Subtractive manufacturing removes material to create precise parts, offering excellent accuracy and surface finish for complex designs. This process is ideal for producing prototypes and components with tight tolerances in industries like aerospace and automotive. Discover how subtractive methods can enhance your production workflow by reading the full article.

Table of Comparison

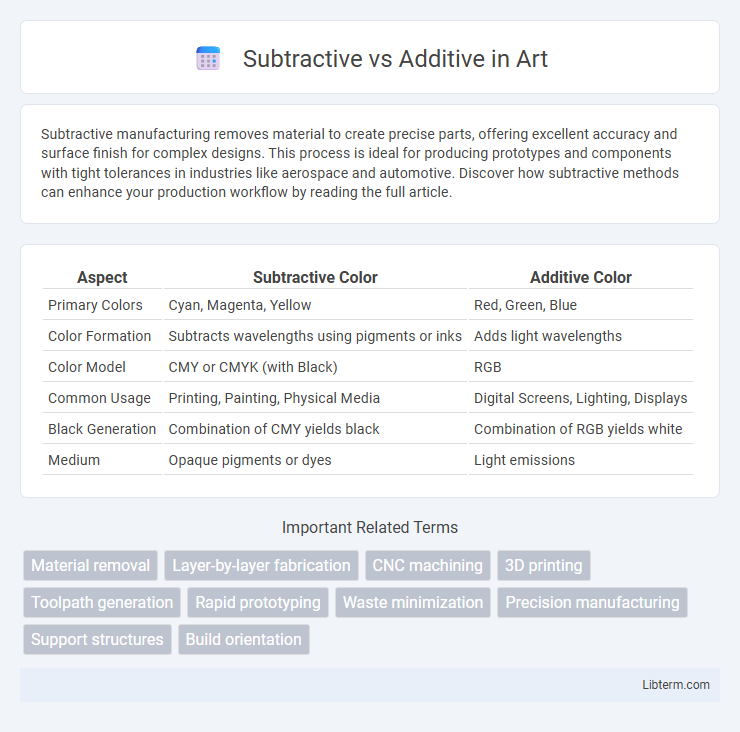

| Aspect | Subtractive Color | Additive Color |

|---|---|---|

| Primary Colors | Cyan, Magenta, Yellow | Red, Green, Blue |

| Color Formation | Subtracts wavelengths using pigments or inks | Adds light wavelengths |

| Color Model | CMY or CMYK (with Black) | RGB |

| Common Usage | Printing, Painting, Physical Media | Digital Screens, Lighting, Displays |

| Black Generation | Combination of CMY yields black | Combination of RGB yields white |

| Medium | Opaque pigments or dyes | Light emissions |

Introduction to Subtractive and Additive Processes

Subtractive and additive processes are fundamental techniques in manufacturing and digital imaging that involve different approaches to creating objects and colors. Subtractive processes remove material from a solid block, like carving or milling, often used in machining metals and woodworking. Additive processes build objects layer by layer, primarily seen in 3D printing and digital displays, where colors are created by mixing light rather than pigments.

Defining Subtractive Manufacturing

Subtractive manufacturing is a process that removes material from a solid block to create a desired shape using tools such as mills, lathes, or CNC machines. This method achieves precise dimensions and surface finishes by cutting, drilling, or grinding raw materials like metal, plastic, or wood. Unlike additive manufacturing, subtractive techniques start with excess material and shape parts through material removal, making it ideal for producing durable components with tight tolerances.

Overview of Additive Manufacturing

Additive manufacturing builds objects layer by layer from digital models, using materials such as plastics, metals, or resins to create complex geometries with minimal waste. This process contrasts with subtractive manufacturing, which removes material from a solid block through machining or cutting, often resulting in higher material loss. Additive techniques enable rapid prototyping, customization, and efficient production of lightweight structures difficult to achieve with traditional subtractive methods.

Core Differences Between Subtractive and Additive Methods

Subtractive methods involve removing material from a solid block using tools like mills or lathes to shape the final product, focusing on precision and surface finish. Additive methods build objects layer by layer, primarily through techniques like 3D printing, enabling complex geometries and material efficiency. The core difference lies in subtractive manufacturing reducing material, while additive manufacturing builds up material to create parts.

Materials Used in Each Manufacturing Process

Subtractive manufacturing primarily uses solid materials such as metal blocks, plastic sheets, and wood, which are shaped by removing excess material through milling, drilling, or cutting. Additive manufacturing, or 3D printing, relies on materials like thermoplastic filaments, photopolymers, metal powders, and resins that are deposited layer by layer to build the final object. The selection of materials in subtractive processes is limited by machinability and density, while additive processes allow for greater material diversity, including composites and biomaterials, due to controlled layering techniques.

Advantages of Subtractive Manufacturing

Subtractive manufacturing offers precise material removal, enabling the creation of complex geometries with high accuracy and smooth surface finishes. It supports a wide range of materials, including metals, plastics, and composites, making it versatile for industries such as aerospace, automotive, and medical devices. The process ensures consistency and repeatability in production, which reduces waste and lowers overall manufacturing costs.

Benefits of Additive Manufacturing

Additive manufacturing offers significant benefits including complex geometries production that traditional subtractive methods cannot achieve, leading to material efficiency by minimizing waste. It enables rapid prototyping, accelerating product development cycles and reducing time-to-market. Customization and on-demand production further enhance operational flexibility and reduce inventory costs.

Applications and Industry Use Cases

Subtractive manufacturing is widely used in industries such as aerospace, automotive, and tooling for producing precise metal and plastic components through machining processes like milling and turning. Additive manufacturing, or 3D printing, finds application in prototyping, medical implants, and customized consumer products by building parts layer-by-layer from digital models. Both methods optimize production efficiency, with subtractive suited for high-volume, complex geometry parts and additive enabling rapid iteration and lightweight designs in sectors like healthcare and aerospace.

Sustainability and Environmental Impact

Subtractive manufacturing typically involves material removal processes that generate waste and consume significant energy, leading to a higher environmental footprint compared to additive manufacturing. Additive manufacturing, or 3D printing, builds objects layer-by-layer using only necessary material, reducing waste and energy usage, making it a more sustainable option in production. Industries adopting additive techniques experience improved resource efficiency and lower carbon emissions, advancing circular economy goals and environmental sustainability.

Future Trends: Subtractive vs Additive Technologies

Future trends in manufacturing indicate a significant shift towards additive technologies due to their ability to produce complex geometries with less material waste and faster prototyping cycles compared to traditional subtractive methods. The rise of industry 4.0 and advancements in 3D printing materials are accelerating the adoption of additive manufacturing in aerospace, automotive, and healthcare sectors. Despite this, subtractive techniques remain essential for high-precision machining, necessitating hybrid approaches that combine the strengths of both methods for optimized production efficiency.

Subtractive Infographic

libterm.com

libterm.com