Lithography is a printing technique that relies on the immiscibility of oil and water to transfer images from a flat surface to paper or other materials. This process allows for the precise reproduction of artwork and text with high detail and quality. Explore the full article to discover how lithography has evolved and its applications in modern printing.

Table of Comparison

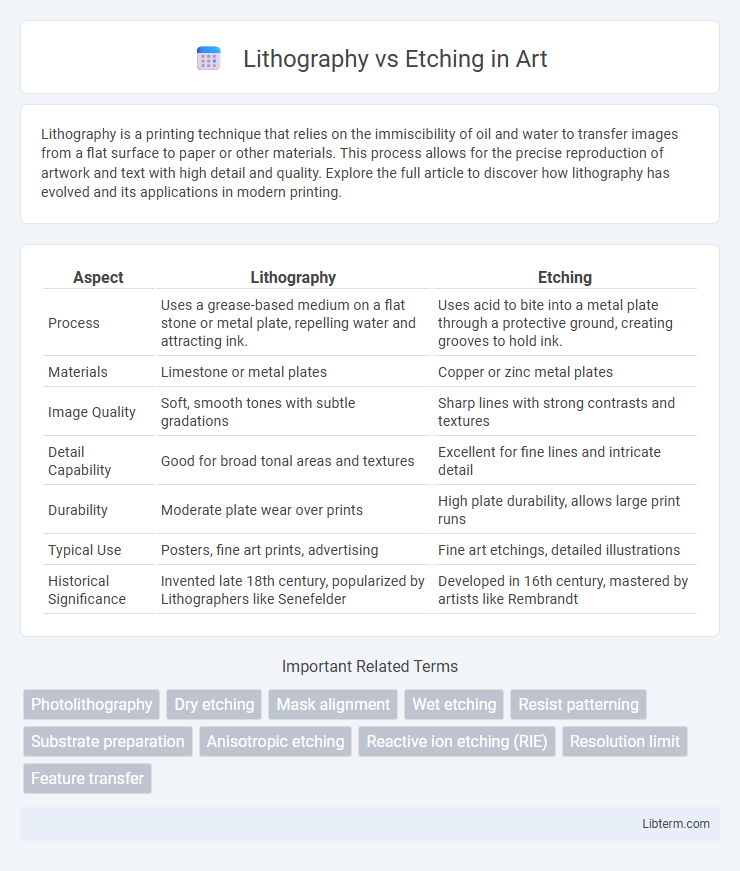

| Aspect | Lithography | Etching |

|---|---|---|

| Process | Uses a grease-based medium on a flat stone or metal plate, repelling water and attracting ink. | Uses acid to bite into a metal plate through a protective ground, creating grooves to hold ink. |

| Materials | Limestone or metal plates | Copper or zinc metal plates |

| Image Quality | Soft, smooth tones with subtle gradations | Sharp lines with strong contrasts and textures |

| Detail Capability | Good for broad tonal areas and textures | Excellent for fine lines and intricate detail |

| Durability | Moderate plate wear over prints | High plate durability, allows large print runs |

| Typical Use | Posters, fine art prints, advertising | Fine art etchings, detailed illustrations |

| Historical Significance | Invented late 18th century, popularized by Lithographers like Senefelder | Developed in 16th century, mastered by artists like Rembrandt |

Introduction to Lithography and Etching

Lithography is a printing technique that uses a flat surface treated to repel ink except where it is required for printing, relying on the immiscibility of oil and water. Etching is an intaglio printmaking process where acid is used to bite into a metal plate, creating recessed lines that hold ink for printing. Both methods are foundational in art and manufacturing, offering distinct approaches to image creation through surface preparation and ink application.

Overview of Lithography Techniques

Lithography techniques primarily involve transferring patterns onto a substrate using light-sensitive chemicals, with key methods including photolithography, electron-beam lithography, and nanoimprint lithography. Photolithography utilizes ultraviolet light to create fine circuit patterns, making it the foundation of semiconductor manufacturing. Electron-beam lithography offers higher resolution by directly writing patterns with a focused electron beam, suitable for prototype and research applications.

Fundamentals of Etching Processes

Etching processes fundamentally involve the controlled removal of material from a substrate surface through chemical or physical means, essential for pattern transfer in microfabrication. Common etching types include wet etching, using liquid chemicals to dissolve specific materials, and dry etching, which employs plasma or reactive gases to achieve anisotropic profiles. Precise control over etching parameters such as time, temperature, and etchant concentration ensures high-resolution pattern fidelity and selective material removal, critical in semiconductor device manufacturing.

Key Differences Between Lithography and Etching

Lithography involves transferring a pattern onto a surface through a chemical process using a photosensitive resist, while etching removes material by chemical or physical means to create the desired pattern. Lithography primarily defines the image on the substrate with high precision, whereas etching physically alters the substrate to produce the design. The main difference lies in lithography being a patterning technique and etching being a material removal process, essential in semiconductor manufacturing and microfabrication.

Applications in Microfabrication

Lithography enables high-resolution patterning crucial for microelectronic device fabrication and integrated circuits by transferring intricate designs onto substrates. Etching complements this process by selectively removing material to create the desired microstructures, essential for MEMS devices and semiconductor manufacturing. Together, lithography and etching define feature dimensions and shapes, driving advancements in microfabrication technologies.

Materials Used in Lithography and Etching

Lithography primarily utilizes photoresist materials such as positive and negative resists, which are sensitive to UV light and allow pattern transfer onto silicon wafers. Etching involves materials like acids (e.g., hydrofluoric acid for silicon dioxide) or plasma gases (e.g., CF4, SF6) for removing or sculpting specific layers on the substrate. These chemical and plasma etchants are selected based on the material compatibility and desired precision in pattern definition during semiconductor fabrication.

Advantages and Limitations

Lithography offers high precision and the ability to create intricate patterns at nanoscale, making it essential for semiconductor manufacturing and microfabrication. Its limitations include high cost, complex equipment, and sensitivity to environmental factors such as dust and vibrations. Etching provides versatility by enabling selective material removal with chemical or plasma processes, but it can suffer from issues like undercutting, limited resolution, and potential damage to underlying layers.

Process Workflow Comparison

Lithography involves creating patterns on a substrate using a photoresist layer exposed to light through a mask, followed by development to form a precise template for subsequent processing. Etching removes material from the substrate either through chemical (wet etching) or plasma-based (dry etching) methods guided by the lithographically defined patterns. The workflow starts with lithographic patterning to define specific areas, then moves to etching to transfer that pattern into the substrate, highlighting lithography's role in pattern creation and etching's function in material removal.

Innovations and Future Trends

Innovations in lithography, such as extreme ultraviolet (EUV) lithography, enable semiconductor manufacturing with feature sizes below 5 nanometers, significantly advancing chip performance and density. Etching techniques have evolved with atomic layer etching (ALE), offering precise material removal at the atomic scale, crucial for next-generation device fabrication. Future trends indicate integration of AI-driven process controls in both lithography and etching to enhance accuracy, reduce defects, and enable complex 3D nanostructures for applications in quantum computing and advanced photonics.

Choosing the Right Technique: Factors to Consider

Choosing the right technique between lithography and etching depends on factors such as the desired level of detail, production volume, and material type. Lithography excels in producing high volumes with consistent detail on smooth surfaces, while etching allows for deeper textures and is ideal for intricate designs on metals. Consideration of cost, time efficiency, and final aesthetic also plays a crucial role in determining the most suitable method.

Lithography Infographic

libterm.com

libterm.com