MDF (Medium-Density Fiberboard) offers a smooth, uniform surface ideal for painting or veneering, making it a popular choice in furniture and cabinetry. Its engineered composition ensures stability and resistance to warping compared to natural wood, providing durability for various interior applications. Discover more about MDF's benefits, uses, and care tips to enhance your next woodworking project by reading the full article.

Table of Comparison

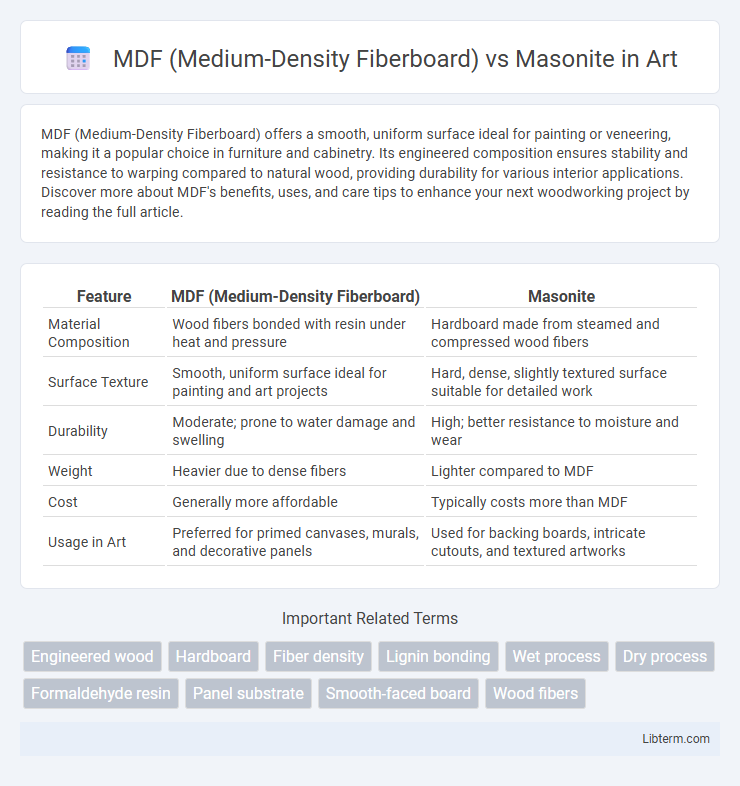

| Feature | MDF (Medium-Density Fiberboard) | Masonite |

|---|---|---|

| Material Composition | Wood fibers bonded with resin under heat and pressure | Hardboard made from steamed and compressed wood fibers |

| Surface Texture | Smooth, uniform surface ideal for painting and art projects | Hard, dense, slightly textured surface suitable for detailed work |

| Durability | Moderate; prone to water damage and swelling | High; better resistance to moisture and wear |

| Weight | Heavier due to dense fibers | Lighter compared to MDF |

| Cost | Generally more affordable | Typically costs more than MDF |

| Usage in Art | Preferred for primed canvases, murals, and decorative panels | Used for backing boards, intricate cutouts, and textured artworks |

What is MDF?

MDF (Medium-Density Fiberboard) is an engineered wood product made by compressing wood fibers with resin under heat and pressure, resulting in a smooth, dense panel ideal for cabinetry, furniture, and molding. Its uniform texture allows for easy machining, painting, and finishing compared to natural wood, making it a versatile choice in construction and interior design. Unlike Masonite, which is produced by steam-cooking and pressure-molding wood fibers into hard boards, MDF offers a finer surface and greater density for detailed work and consistent durability.

What is Masonite?

Masonite is a type of hardboard made from wood fibers that are steam-cooked and then formed into dense, smooth panels using high pressure and temperature. It offers a durable, moisture-resistant surface often used for doors, wall paneling, and furniture backing. Unlike MDF, which is made from wood fibers bonded with resin, Masonite provides greater strength and better resistance to warping and swelling.

Composition and Manufacturing Differences

MDF (Medium-Density Fiberboard) is composed of fine wood fibers bonded together with resin under heat and pressure, creating a dense, smooth panel ideal for precision woodworking. Masonite, also known as hardboard, is made by steaming and pressing wood fibers, resulting in a highly compressed, durable, and smooth surface with a unique hard, glossy finish. The key manufacturing difference lies in MDF's use of synthetic resin adhesives and the wet process for fiber bonding, while Masonite is produced through a dry process with natural lignin acting as a binder during high heat and pressure.

Strength and Durability Comparison

MDF (Medium-Density Fiberboard) offers consistent strength and smooth surface ideal for detailed woodworking but is less moisture-resistant and prone to swelling when exposed to water. Masonite, a type of hardboard made from wood fibers, provides superior impact resistance and durability, especially in exterior or high-traffic applications due to its high-density and moisture-resistant properties. When comparing strength and durability, Masonite outperforms MDF in resisting wear, impact, and moisture damage, making it a more robust choice for long-lasting, heavy-duty projects.

Moisture Resistance: MDF vs Masonite

MDF (Medium-Density Fiberboard) typically exhibits lower moisture resistance compared to Masonite, as it is prone to swelling and warping when exposed to high humidity or water. Masonite, made through a steam-cooked and pressure-molded process of wood fibers, features a harder, denser surface that provides superior resistance to moisture and water damage. For applications involving exposure to damp environments, Masonite is generally the preferred choice due to its enhanced durability and water-resistant properties.

Workability and Machining

MDF (Medium-Density Fiberboard) offers superior workability due to its uniform density and smooth surface, enabling precise machining and easy cutting, drilling, and shaping without splintering. Masonite, a hardboard made from compressed wood fibers, is denser and more brittle, making it less forgiving during machining and more prone to chipping or cracking when cut or routed. For projects requiring detailed work and clean edges, MDF is generally preferred for its consistent machinability and ease of sanding.

Surface Finish and Paintability

MDF (Medium-Density Fiberboard) offers a smooth, uniform surface that is highly ideal for paint application, allowing for a flawless finish with minimal preparation. Masonite, made from hardboard, has a denser, harder surface that may require sanding or priming to achieve comparable paint adhesion and durability. Both materials respond well to paint, but MDF's consistent surface texture enhances the final coat's appearance, making it a preferred choice for detailed painting projects.

Typical Uses and Applications

MDF (Medium-Density Fiberboard) is commonly used in furniture manufacturing, cabinetry, and interior paneling due to its smooth surface and ease of machining, making it ideal for painted finishes and intricate detailing. Masonite, a type of hardboard made from steam-cooked and pressure-molded wood fibers, is frequently utilized for door skins, wall panels, and underlayment because of its strength, moisture resistance, and durability. Both materials serve distinct functions in construction and woodworking, with MDF preferred for precision work indoors and Masonite favored for structural and protective applications.

Cost Comparison: MDF vs Masonite

MDF (Medium-Density Fiberboard) typically costs less than Masonite per sheet, making it a budget-friendly option for many woodworking and furniture projects. Masonite, known for its durability and smooth surface, can be priced higher due to its manufacturing process and density. When comparing costs, MDF offers affordability and consistency, while Masonite may justify its higher price with enhanced strength and moisture resistance.

Which is Better for Your Project?

MDF (Medium-Density Fiberboard) offers a smooth, consistent surface ideal for painting and precise cutting, making it excellent for indoor furniture and cabinetry. Masonite, known for its durability and water-resistant properties, is better suited for exterior projects or applications requiring impact resistance. Choosing between MDF and Masonite depends on the project's environment, with MDF preferred for detailed interior work and Masonite favored for robust, weather-exposed surfaces.

MDF (Medium-Density Fiberboard) Infographic

libterm.com

libterm.com