Blowdown is a critical process in industrial boilers used to remove impurities and sediment from the system, ensuring optimal performance and extending equipment lifespan. Properly managing blowdown reduces scaling and corrosion, which can lead to costly repairs and downtime. Discover how the right blowdown techniques can protect your boiler and improve efficiency by reading the full article.

Table of Comparison

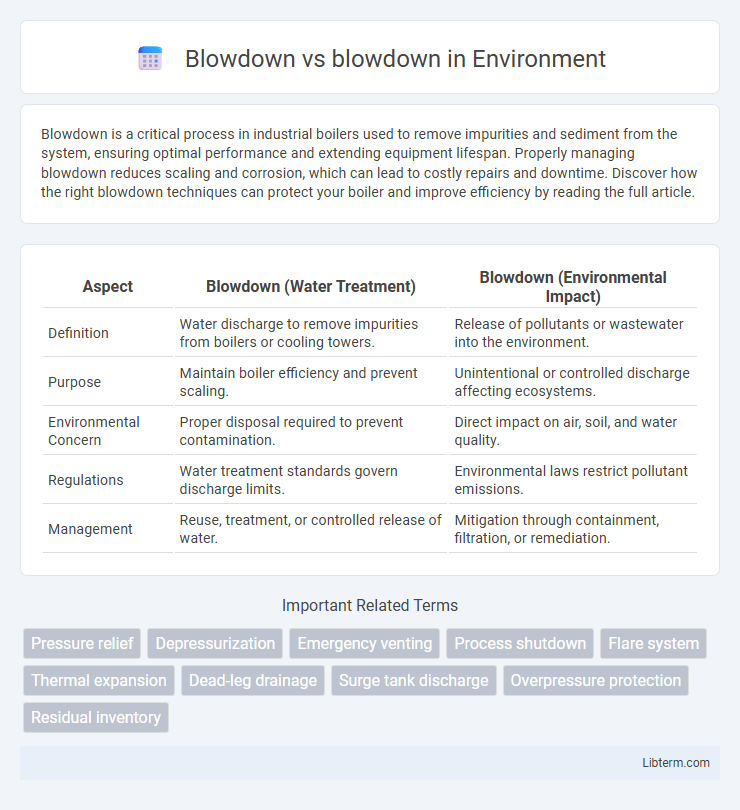

| Aspect | Blowdown (Water Treatment) | Blowdown (Environmental Impact) |

|---|---|---|

| Definition | Water discharge to remove impurities from boilers or cooling towers. | Release of pollutants or wastewater into the environment. |

| Purpose | Maintain boiler efficiency and prevent scaling. | Unintentional or controlled discharge affecting ecosystems. |

| Environmental Concern | Proper disposal required to prevent contamination. | Direct impact on air, soil, and water quality. |

| Regulations | Water treatment standards govern discharge limits. | Environmental laws restrict pollutant emissions. |

| Management | Reuse, treatment, or controlled release of water. | Mitigation through containment, filtration, or remediation. |

Understanding Blowdown: Definition and Purpose

Blowdown is a controlled process used to remove impurities and maintain the proper concentration of dissolved solids in boiler systems, preventing scale and corrosion. Effective blowdown ensures system efficiency, safety, and longevity by discharging concentrated water and replacing it with fresh makeup water. Understanding blowdown parameters and techniques is essential for optimizing boiler operation and reducing operational costs.

Types of Blowdown: Intermittent vs Continuous

Blowdown refers to the controlled removal of water or steam from boilers and pressure vessels to manage impurities and maintain optimal pressure levels. Intermittent blowdown is performed periodically to remove sludge and sediments, preserving water quality and preventing corrosion, while continuous blowdown operates constantly to control dissolved solids levels and maintain consistent boiler water chemistry. Understanding the specific requirements and operational conditions determines the appropriate choice between intermittent and continuous blowdown for efficient boiler maintenance.

Key Differences Between Blowdown Methods

Blowdown methods in industrial boilers primarily differ in the approach and purpose: continuous blowdown involves a steady removal of water to control concentration of dissolved solids, while intermittent blowdown is performed periodically to eliminate sludge and sediment buildup. Continuous blowdown maintains water quality for efficient heat transfer and prevents scale formation, whereas intermittent blowdown targets the settling of impurities at the bottom of the boiler drum. Selecting the appropriate blowdown technique depends on boiler design, operational parameters, and water quality management requirements.

Applications in Industrial Systems

Blowdown in industrial systems refers to the controlled removal of water or steam containing impurities to maintain system efficiency and prevent corrosion or scaling. Blowdown processes are critical in boilers, cooling towers, and heat exchangers to regulate concentration cycles and protect equipment integrity. Effective blowdown applications optimize energy consumption, enhance operational safety, and extend the lifespan of industrial machinery.

Blowdown in Boilers: Processes and Benefits

Blowdown in boilers involves the controlled removal of water to eliminate dissolved solids and sludge, preventing scale formation and corrosion within the boiler system. This process enhances boiler efficiency, extends equipment lifespan, and reduces maintenance costs by maintaining optimal water chemistry. Regular blowdown ensures safer operation by managing steam quality and minimizing the risk of boiler tube failure.

Cooling Tower Blowdown Explained

Cooling tower blowdown refers to the process of removing a portion of water from the cooling system to control the concentration of dissolved solids, such as calcium, silica, and chloride. Effective blowdown management reduces scale formation, corrosion, and biological growth, ensuring optimal heat transfer efficiency and prolonging equipment lifespan. Differentiating between continuous and intermittent blowdown strategies allows plants to balance water conservation with system performance requirements.

Environmental Impact and Water Management

Blowdown in industrial water systems, particularly in boilers and cooling towers, involves discharging concentrated water containing dissolved solids to control water quality, which can lead to environmental pollution if not properly treated. Managing blowdown requires advanced water treatment technologies and recycling methods to minimize freshwater consumption and reduce the release of contaminants into natural water bodies. Effective blowdown management improves environmental sustainability by lowering chemical usage, conserving water resources, and preventing harmful thermal and chemical discharges.

Safety Considerations During Blowdown

Blowdown in industrial settings involves depressurizing equipment or pipelines to safely release excess pressure, preventing catastrophic failures. Safety considerations during blowdown emphasize controlled venting, proper placement of blowdown valves, and ensuring personnel are clear of discharge areas to avoid exposure to high-pressure fluids or hazardous gases. Implementing adequate monitoring systems and emergency shutdown protocols minimizes risks associated with rapid depressurization and potential equipment damage.

Cost Implications of Different Blowdown Strategies

Blowdown strategies significantly impact operational costs in industrial systems by balancing water quality maintenance and energy consumption. Frequent blowdown reduces scaling and corrosion risks, minimizing long-term maintenance expenses but increases water and chemical usage costs. Conversely, reduced blowdown frequency lowers immediate resource costs yet can escalate equipment degradation and repair expenditure due to higher impurity concentration.

Best Practices for Efficient Blowdown Control

Blowdown control in industrial systems requires precise management to maintain optimal pressure and remove contaminants effectively without wasting resources. Implementing best practices such as real-time monitoring, automated control valves, and routine maintenance ensures efficient blowdown processes that reduce water and energy consumption. Optimizing blowdown intervals based on system conductivity and pressure data maximizes operational efficiency while minimizing environmental impact and operational costs.

Blowdown Infographic

libterm.com

libterm.com