A condensate separator efficiently removes liquids from gas streams, ensuring optimal system performance and preventing equipment damage. Proper maintenance and selection of the right condensate separator can significantly enhance operational reliability and reduce downtime. Discover how choosing the best condensate separator can improve Your processes by exploring the full article.

Table of Comparison

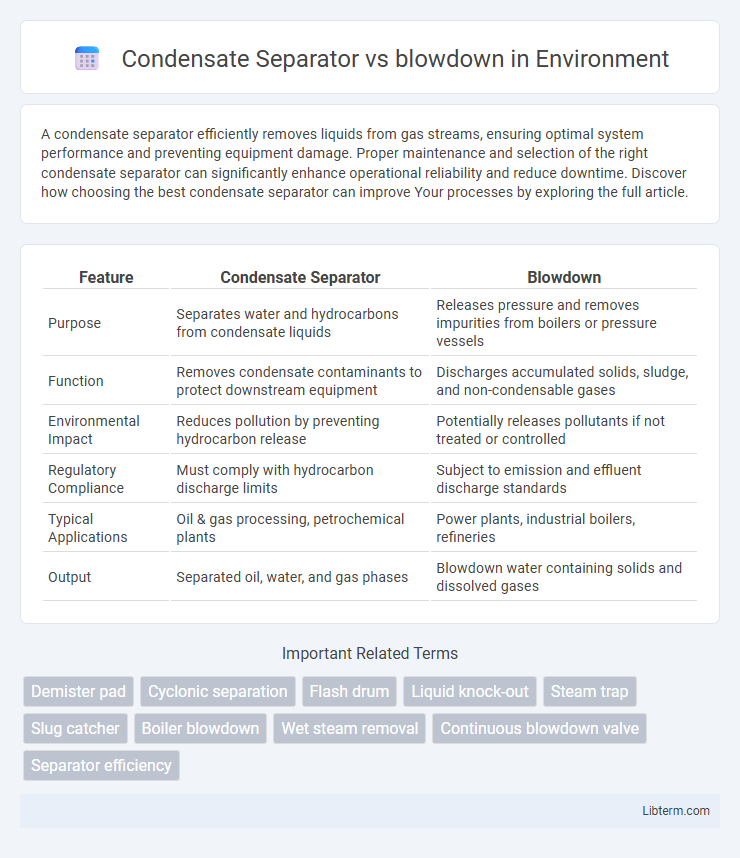

| Feature | Condensate Separator | Blowdown |

|---|---|---|

| Purpose | Separates water and hydrocarbons from condensate liquids | Releases pressure and removes impurities from boilers or pressure vessels |

| Function | Removes condensate contaminants to protect downstream equipment | Discharges accumulated solids, sludge, and non-condensable gases |

| Environmental Impact | Reduces pollution by preventing hydrocarbon release | Potentially releases pollutants if not treated or controlled |

| Regulatory Compliance | Must comply with hydrocarbon discharge limits | Subject to emission and effluent discharge standards |

| Typical Applications | Oil & gas processing, petrochemical plants | Power plants, industrial boilers, refineries |

| Output | Separated oil, water, and gas phases | Blowdown water containing solids and dissolved gases |

Introduction to Condensate Separator and Blowdown

Condensate separators efficiently remove liquid condensate from steam or gas streams, enhancing process safety and equipment longevity by preventing corrosion and water hammer. Blowdown systems control the concentration of impurities in boilers by periodically discharging a portion of the water, maintaining water quality and preventing scale buildup. Both components are essential in steam systems, with condensate separators focusing on liquid removal and blowdown ensuring optimal water chemistry.

Definition and Function of Condensate Separators

Condensate separators are specialized vessels designed to remove liquid condensate from steam or gas lines, preventing water hammer and corrosion in equipment. These separators function by slowing down the steam flow, allowing condensate to coalesce and be drained off efficiently, thus maintaining system integrity and operational efficiency. In contrast, blowdown systems focus on removing impurities and excess water from boilers to control water chemistry and pressure.

Understanding Blowdown in Steam Systems

Blowdown in steam systems is the controlled removal of water containing high levels of dissolved solids to prevent scale and corrosion in boilers. A condensate separator plays a critical role by separating condensate from steam, ensuring clean condensate returns without contaminants that necessitate frequent blowdown. Understanding blowdown rates and methods optimizes boiler efficiency, prolongs equipment life, and maintains system integrity.

Key Differences Between Condensate Separators and Blowdown

Condensate separators efficiently remove liquid condensate from steam or gas streams, preventing equipment damage and improving system efficiency, while blowdown systems primarily manage boiler water quality by discharging impurities and dissolved solids to control boiler pressure and maintain safe operation. Condensate separators operate continuously to separate and collect condensate for reuse or disposal, whereas blowdown is performed periodically to reduce the concentration of contaminants in the boiler. The key difference lies in their function: condensate separators focus on phase separation of liquids from steam, and blowdown focuses on water chemistry control within boilers.

Applications of Condensate Separators

Condensate separators are primarily used in natural gas processing and steam systems to efficiently remove liquid condensate from gas streams, ensuring the protection of downstream equipment and improving the overall system performance. Applications of condensate separators include gas transmission pipelines, gas processing plants, and HVAC systems where separating water and hydrocarbons from gas flow prevents corrosion and piping damage. Blowdown systems, by contrast, are mainly designed for pressure relief and removal of contaminants, making condensate separators essential for maintaining gas quality and operational safety in continuous gas and steam flow environments.

Typical Uses of Blowdown Processes

Blowdown processes are typically used to remove impurities, solids, and sludge from boiler water to maintain water quality and prevent corrosion or scaling. These procedures help control dissolved solids concentration, ensuring operational efficiency and extending equipment lifespan. In contrast, condensate separators focus on separating condensate from steam lines to protect downstream equipment and optimize steam system performance.

Efficiency Impact: Condensate Separator vs Blowdown

Condensate separators enhance efficiency by effectively removing liquid droplets from gas streams, minimizing corrosion and equipment damage while optimizing downstream process performance. Blowdown systems, though necessary for pressure control and safety, can lead to higher operational inefficiencies due to energy loss and increased emissions when releasing pressurized fluids. Comparing both, condensate separators provide superior efficiency impact by enabling energy recovery and reducing maintenance costs associated with blowdown cycles.

Maintenance and Operational Considerations

Condensate separators require regular inspection to prevent liquid carryover and ensure efficient phase separation, while blowdown systems demand routine cleaning to avoid scale and corrosion buildup within blowdown tanks and piping. Operational considerations emphasize optimizing pressure and temperature settings in condensate separators to maintain separation efficiency, whereas blowdown operations focus on controlled pressure release to protect system integrity and reduce environmental impact. Effective maintenance schedules and operational protocols for both systems are critical for minimizing downtime and extending equipment lifespan in steam and condensate handling processes.

Cost Implications of Each System

Condensate separators typically involve higher upfront costs due to complex equipment and installation requirements but offer long-term savings by efficiently recovering valuable condensate and reducing wastewater treatment expenses. Blowdown systems generally have lower initial investment costs but may incur increased operational expenses from energy losses and handling larger volumes of contaminated water. Choosing between the two hinges on balancing initial capital expenditures against ongoing operational and maintenance costs associated with water treatment and resource recovery.

Choosing the Right Solution: Factors to Consider

Selecting between a condensate separator and blowdown system hinges on operational requirements, fluid characteristics, and environmental regulations. Condensate separators excel in removing oil and water mixtures from steam condensate, enhancing equipment protection and reducing emissions, while blowdown systems primarily manage boiler water quality by expelling concentrated impurities. Evaluating factors such as system pressure, contaminant levels, disposal methods, and maintenance complexity ensures optimal performance and compliance with industry standards.

Condensate Separator Infographic

libterm.com

libterm.com