Suspension systems play a crucial role in vehicle performance by absorbing shocks from uneven road surfaces, enhancing ride comfort, and ensuring better handling and stability. Proper maintenance and timely repairs of suspension components like springs, shock absorbers, and struts can significantly improve Your driving experience and safety. Explore the rest of the article to understand how suspension works and tips for keeping it in optimal condition.

Table of Comparison

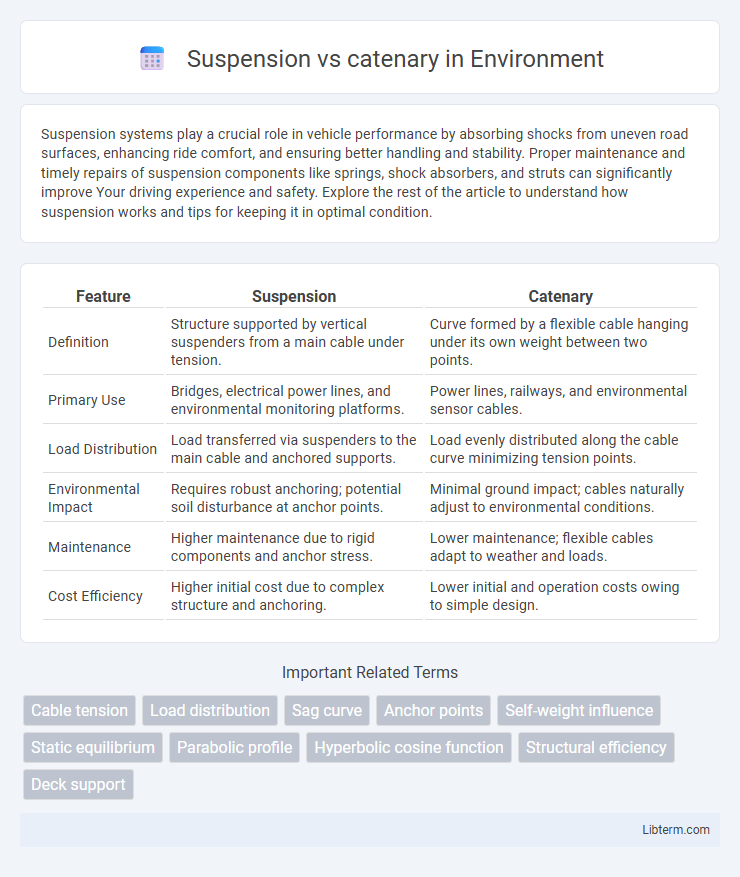

| Feature | Suspension | Catenary |

|---|---|---|

| Definition | Structure supported by vertical suspenders from a main cable under tension. | Curve formed by a flexible cable hanging under its own weight between two points. |

| Primary Use | Bridges, electrical power lines, and environmental monitoring platforms. | Power lines, railways, and environmental sensor cables. |

| Load Distribution | Load transferred via suspenders to the main cable and anchored supports. | Load evenly distributed along the cable curve minimizing tension points. |

| Environmental Impact | Requires robust anchoring; potential soil disturbance at anchor points. | Minimal ground impact; cables naturally adjust to environmental conditions. |

| Maintenance | Higher maintenance due to rigid components and anchor stress. | Lower maintenance; flexible cables adapt to weather and loads. |

| Cost Efficiency | Higher initial cost due to complex structure and anchoring. | Lower initial and operation costs owing to simple design. |

Introduction to Suspension and Catenary Structures

Suspension structures use cables suspended between towers to support loads through tension, efficiently spanning long distances with minimal material. Catenary structures follow the natural curve of a flexible cable hanging under its own weight, distributing loads evenly and minimizing bending moments. Both systems optimize material strength and stability, making them ideal for bridges, roofs, and other large-scale architectural applications.

Defining Suspension Bridges

Suspension bridges are defined by their distinctive design, where the roadway is hung from cables draped over towers and anchored firmly at both ends, allowing them to span long distances with minimal support below. The main cables follow a catenary curve, which naturally distributes the weight, but in suspension bridges, these cables are tightly tensioned and connected to vertical suspenders that hold the deck. This combination differentiates suspension bridges from pure catenary structures, optimizing load distribution and enabling flexibility for heavy traffic and environmental forces.

Understanding Catenary Bridges

Catenary bridges leverage cables shaped in a natural catenary curve to efficiently distribute tension forces, optimizing load-bearing capacity with minimal material use. Unlike suspension bridges that rely on parabolic main cables and vertical suspenders, catenary structures emphasize cable tension that follows the true curve of a freely hanging cable under uniform load. Understanding this distinction aids in designing bridges with enhanced structural stability and precise stress management in engineering applications.

Key Differences Between Suspension and Catenary

Suspension and catenary systems differ primarily in their structural behavior and applications; suspension bridges use vertical hangers to transfer loads from the deck to main cables, creating a curved shape due to the deck's weight, while catenary systems refer to cables hanging freely under their own weight forming a pure catenary curve. Suspension cables experience tension influenced by external loads, whereas catenary cables primarily support self-weight with minimal external forces. The key difference lies in load distribution: suspension bridges carry dynamic loads across large spans, while catenary forms are ideal for static applications like electrical wiring or cable-supported roofing.

Engineering Principles Involved

Suspension bridges utilize vertical suspenders connected to main cables that transfer loads directly to towers and anchorages, optimizing tensile forces and minimizing bending moments. Catenary systems rely on the natural curve formed by a uniformly loaded flexible cable, distributing tension efficiently along the cable's length with minimal compressive stresses. Both systems exploit gravity and tension mechanics, but suspension bridges incorporate stiffening elements to resist dynamic loads and provide stability.

Load Distribution and Structural Behavior

Suspension bridges transfer loads primarily through cables in tension, distributing weight evenly to the towers and anchorages, resulting in flexible structures capable of spanning long distances with minimal material. In contrast, catenary systems, often seen in overhead power lines or arches, form natural curves under uniform load, balancing compression and tension forces along the curve for efficient load transfer. The suspension design allows for dynamic load adaptability, while catenary structures emphasize geometric stability, affecting their respective structural behaviors and load management strategies.

Construction Methods Compared

Suspension bridges use main cables anchored at both ends, supporting vertical suspenders that hold the deck, allowing for longer spans and flexible load distribution. Catenary systems feature cables hanging freely in a natural curve between two anchor points, often used in lightweight structural applications or overhead power lines, with simpler construction but limited load capacity. Construction of suspension bridges involves complex anchorage and tower erection, whereas catenary methods rely on tensioning cables under gravity, resulting in faster installation and lower material demands.

Advantages and Disadvantages

Suspension bridges offer significant advantages such as the ability to span long distances with fewer piers, providing ample clearance below for navigation, and flexibility under dynamic loads like wind and traffic. However, they require substantial anchorages and are susceptible to oscillations and higher maintenance costs due to exposed cables. Catenary structures efficiently distribute loads through their naturally curved cables, minimizing bending moments and material use, but they typically have limited span length and require precise tensioning to maintain structural integrity.

Common Applications in Modern Infrastructure

Suspension bridges dominate modern long-span applications such as the Golden Gate Bridge and Akashi Kaikyo Bridge, where their ability to support heavy loads and withstand dynamic forces is crucial. Catenary structures are frequently employed in overhead electrical lines, cable-supported roofs, and large-scale pedestrian bridges, leveraging the natural curve of cables to optimize tension distribution. Both systems enhance infrastructure durability and performance, with suspension suited for vehicular traffic and catenary forms ideal for lightweight and flexible architectural designs.

Future Trends in Bridge Design

Future trends in bridge design emphasize advanced materials and hybrid structures that combine suspension and catenary principles to enhance load distribution and resilience. Emerging technologies like smart sensors and AI-driven monitoring systems optimize structural health and maintenance efficiency. Innovations in aerodynamic shaping and dynamic response control further contribute to the sustainability and longevity of modern bridge solutions.

Suspension Infographic

libterm.com

libterm.com