Trusses provide a lightweight yet strong framework commonly used in construction to support roofs, bridges, and towers by efficiently distributing loads. Their triangular design enhances stability and reduces material use, making them both economical and durable. Explore the rest of this article to understand how trusses can benefit your next building project.

Table of Comparison

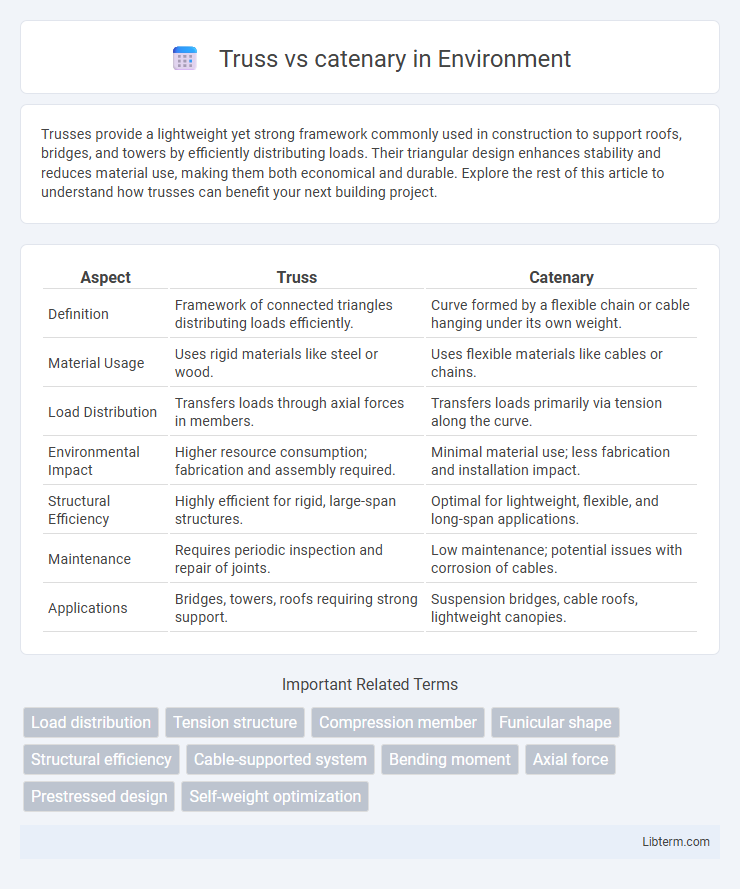

| Aspect | Truss | Catenary |

|---|---|---|

| Definition | Framework of connected triangles distributing loads efficiently. | Curve formed by a flexible chain or cable hanging under its own weight. |

| Material Usage | Uses rigid materials like steel or wood. | Uses flexible materials like cables or chains. |

| Load Distribution | Transfers loads through axial forces in members. | Transfers loads primarily via tension along the curve. |

| Environmental Impact | Higher resource consumption; fabrication and assembly required. | Minimal material use; less fabrication and installation impact. |

| Structural Efficiency | Highly efficient for rigid, large-span structures. | Optimal for lightweight, flexible, and long-span applications. |

| Maintenance | Requires periodic inspection and repair of joints. | Low maintenance; potential issues with corrosion of cables. |

| Applications | Bridges, towers, roofs requiring strong support. | Suspension bridges, cable roofs, lightweight canopies. |

Introduction to Truss and Catenary Structures

Truss structures consist of triangular units connected at joints to efficiently distribute loads through axial forces, providing stability and strength in bridges, roofs, and towers. Catenary structures follow the natural curve formed by a flexible cable or chain under its own weight, optimizing tension and minimizing bending moments, commonly seen in suspension bridges and arches. Understanding these distinct load-bearing principles aids engineers in selecting appropriate designs for specific structural requirements and material efficiencies.

Historical Development of Truss and Catenary Designs

Truss designs originated in ancient civilizations, with early examples like the wooden roof trusses of Greek and Roman architecture, evolving through the Industrial Revolution to include steel frameworks that enabled large-scale bridges and buildings. The catenary curve concept emerged from the study of hanging chains and cables, first mathematically described by Leibniz and Johann Bernoulli in the late 17th century, influencing the design of arches and suspension bridges such as Antoni Gaudi's architectural works and the iconic Gateway Arch. Both structural systems reflect advancements in engineering principles, where trusses distribute loads through interconnected triangles, and catenaries optimize the natural shape of tensioned elements under gravity.

Fundamental Principles: Truss vs. Catenary

Trusses rely on a network of straight members connected at nodes, distributing loads primarily through axial tension and compression, which allows for rigid structural frameworks. Catenary structures form naturally curved shapes under uniform gravitational loading, where the load is transferred solely through tension along the cable or chain, optimizing material efficiency. Understanding the fundamental principles reveals trusses excel in resisting bending moments, while catenaries achieve minimal bending stress by following pure tension paths.

Structural Efficiency and Load Distribution

Truss structures offer high structural efficiency by distributing loads through interconnected triangular units that ensure rigidity and minimize material use while effectively handling both compression and tension forces. Catenary systems excel in load distribution by naturally following the shape of uniform gravitational loads, creating pure tension structures that efficiently carry distributed loads with minimal bending moments. Comparing both, trusses are advantageous for spanning longer distances with complex load paths, whereas catenaries optimize material usage under consistent load conditions by leveraging their geometric form for uniform stress distribution.

Common Applications in Modern Construction

Trusses are widely used in modern construction for bridges, roof supports, and towers due to their high strength-to-weight ratio and ease of prefabrication. Catenary structures are commonly applied in suspension bridges, long-span roofs, and cable-supported systems where flexible, tensile elements efficiently distribute loads. Both systems offer unique advantages: trusses excel in compressive and bending-resistant applications, while catenaries provide optimal solutions for tensile stress and aesthetic, lightweight designs.

Material Requirements and Cost Implications

Trusses generally require more material due to numerous interconnected members, increasing both weight and cost, but this structure offers high strength-to-weight ratios suitable for shorter spans. Catenary designs use tensioned cables that require less material overall, leading to lower material costs and lighter structures ideal for longer spans like suspension bridges. However, catenary systems often incur higher installation and maintenance expenses because of specialized cable hardware and anchoring needs.

Design Flexibility and Architectural Aesthetics

Truss systems offer significant design flexibility through their modular and geometric framework, allowing architects to create a wide variety of shapes and spans suitable for both traditional and modern structures. Catenary designs excel in architectural aesthetics by naturally forming elegant, catenary curves that distribute load efficiently and provide visually striking, minimalistic profiles ideal for open, airy spaces. The choice between truss and catenary depends on the project's structural requirements and desired aesthetic impact, with trusses favoring engineered complexity and catenaries showcasing organic simplicity.

Maintenance, Durability, and Lifespan

Truss bridges require regular inspections and occasional replacement of individual members due to potential corrosion and fatigue at connection points, impacting long-term maintenance efforts. Catenary structures, often found in suspension bridges, offer enhanced durability with fewer stress concentrations, reducing frequent repairs and extending overall lifespan. Both designs benefit from corrosion-resistant materials, but catenary systems generally provide superior longevity and reduced upkeep costs over time.

Environmental Impact and Sustainability

Truss structures often require more material and produce higher carbon emissions during manufacturing and construction due to the extensive use of steel or timber. Catenary designs, characterized by their natural curve, minimize material use and optimize load distribution, leading to lower environmental footprints and enhanced sustainability. The adoption of catenary systems promotes resource efficiency and aligns with green building practices through reduced energy consumption and waste generation.

Choosing the Right Structure: Truss or Catenary?

Selecting the right structure between truss and catenary depends on factors such as span length, load distribution, and material efficiency. Truss structures excel in providing rigid support for shorter spans with concentrated loads, utilizing interconnected triangles for optimal strength and minimal material use. Catenary designs suit longer spans and flexible loads, leveraging the natural curve of hanging cables to evenly distribute tension forces and reduce bending moments.

Truss Infographic

libterm.com

libterm.com