Vermicomposting accelerates organic waste decomposition using earthworms, producing nutrient-rich compost ideal for enriching soil fertility and promoting healthy plant growth. This eco-friendly technique reduces landfill waste while enhancing soil structure and moisture retention. Discover how vermicomposting can transform your gardening practices by reading the rest of the article.

Table of Comparison

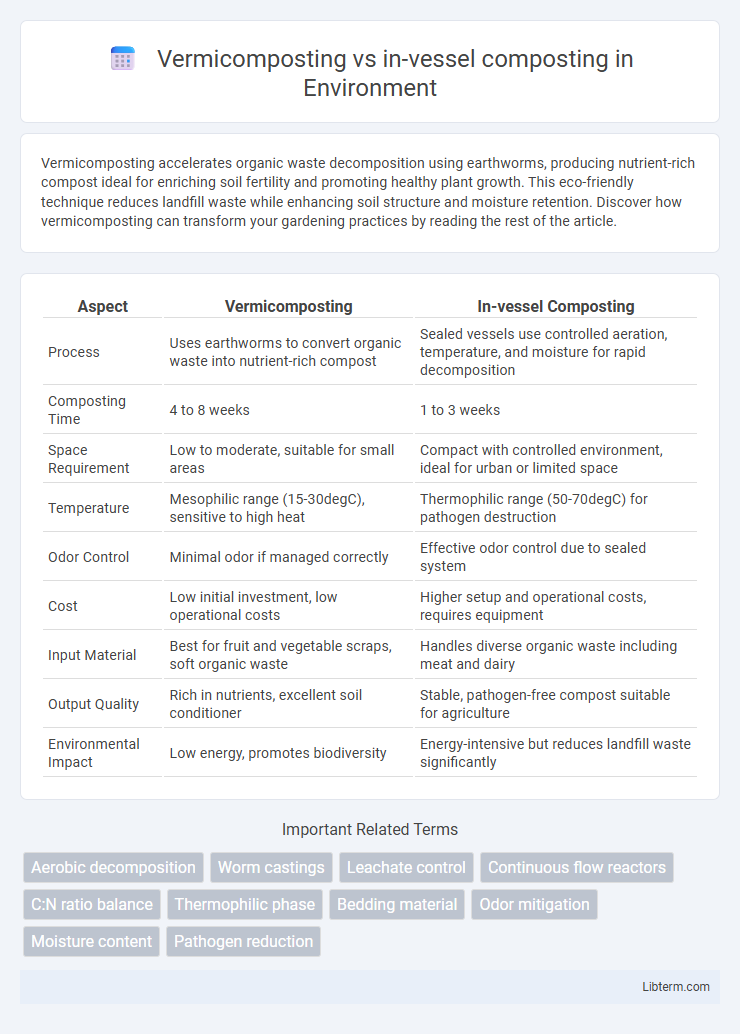

| Aspect | Vermicomposting | In-vessel Composting |

|---|---|---|

| Process | Uses earthworms to convert organic waste into nutrient-rich compost | Sealed vessels use controlled aeration, temperature, and moisture for rapid decomposition |

| Composting Time | 4 to 8 weeks | 1 to 3 weeks |

| Space Requirement | Low to moderate, suitable for small areas | Compact with controlled environment, ideal for urban or limited space |

| Temperature | Mesophilic range (15-30degC), sensitive to high heat | Thermophilic range (50-70degC) for pathogen destruction |

| Odor Control | Minimal odor if managed correctly | Effective odor control due to sealed system |

| Cost | Low initial investment, low operational costs | Higher setup and operational costs, requires equipment |

| Input Material | Best for fruit and vegetable scraps, soft organic waste | Handles diverse organic waste including meat and dairy |

| Output Quality | Rich in nutrients, excellent soil conditioner | Stable, pathogen-free compost suitable for agriculture |

| Environmental Impact | Low energy, promotes biodiversity | Energy-intensive but reduces landfill waste significantly |

Introduction to Vermicomposting and In-Vessel Composting

Vermicomposting utilizes earthworms to convert organic waste into nutrient-rich compost, enhancing soil fertility and structure through microbial activity. In-vessel composting is a controlled aerobic process conducted within sealed containers, allowing precise regulation of temperature, moisture, and airflow for rapid decomposition. Both methods offer sustainable waste management solutions but differ in scale, operational complexity, and ideal feedstock types.

Basic Principles of Vermicomposting

Vermicomposting involves the use of specific earthworm species, such as Eisenia fetida, to decompose organic waste, converting it into nutrient-rich castings through their digestive process. This method requires maintaining optimal conditions like moisture levels between 70-90%, temperatures ranging from 15-25degC, and adequate aeration to ensure worm activity and efficient decomposition. Unlike in-vessel composting, which relies on mechanical aeration and controlled environmental factors in a closed system, vermicomposting depends primarily on biological processes driven by earthworm metabolism.

Core Features of In-Vessel Composting

In-vessel composting features a controlled environment where organic waste is enclosed in a drum, silo, or vessel, optimizing temperature, moisture, and aeration to accelerate decomposition. This method enables efficient management of odor, pests, and pathogens, producing high-quality compost in a shorter timeframe compared to vermicomposting. Its core advantage lies in scalability and suitability for processing diverse organic materials in both small-scale and industrial applications.

Efficiency and Processing Time Comparison

Vermicomposting utilizes earthworms to rapidly break down organic waste, achieving efficient nutrient-rich compost within 2 to 6 weeks, making it ideal for small to medium-scale operations. In-vessel composting accelerates decomposition by controlling temperature, moisture, and aeration, processing large volumes of waste in as little as 1 to 3 weeks with high pathogen kill rates. While vermicomposting excels in producing high-quality humus with lower energy inputs, in-vessel composting offers superior speed and scalability for industrial applications.

Material Inputs and Acceptable Waste Types

Vermicomposting primarily accepts organic kitchen waste, fruit and vegetable scraps, coffee grounds, and paper products, relying on earthworms to break down these materials efficiently. In-vessel composting accommodates a wider range of inputs, including food waste, yard debris, agricultural residues, and some non-organic materials like meat and dairy, due to its controlled, enclosed environment. The ability of in-vessel systems to process diverse and sometimes more challenging waste types contrasts with vermicomposting's preference for finely shredded, non-toxic organic matter optimal for worm digestion.

Environmental Impact and Sustainability

Vermicomposting utilizes earthworms to break down organic waste, producing nutrient-rich vermicast that enhances soil fertility and reduces landfill use, thereby lowering greenhouse gas emissions. In-vessel composting accelerates decomposition within a controlled environment, minimizing odor and pathogen risks while enabling efficient waste processing on a larger scale. Both methods contribute to sustainability by recycling organic waste, but vermicomposting offers greater benefits for soil health and biodiversity, while in-vessel composting supports high-volume waste management and emission control.

Space, Infrastructure, and Cost Considerations

Vermicomposting requires minimal space with simple infrastructure, making it ideal for small-scale or urban settings, and involves low upfront and maintenance costs due to the natural use of earthworms. In-vessel composting demands larger space and specialized, often costly, enclosed systems with controlled aeration, temperature, and moisture, suitable for high-volume organic waste processing. The choice hinges on budget availability, spatial constraints, and the scale of organic waste management needs.

End Product Quality and Nutrient Value

Vermicomposting produces high-quality end products rich in essential nutrients such as nitrogen, phosphorus, and potassium, enhanced by microbial activity and worm castings that improve soil aeration and water retention. In-vessel composting generates stabilized compost with consistent nutrient levels due to controlled temperature and moisture, but it may lack the microbial diversity found in vermicompost. The nutrient value in vermicompost is often superior for promoting plant growth and soil health, whereas in-vessel composting offers faster processing times with predictable results.

Scalability for Home and Commercial Use

Vermicomposting offers scalable solutions for home use due to its low space requirements and ability to process small to moderate organic waste volumes efficiently. In-vessel composting provides high scalability for commercial operations, featuring enclosed systems that accelerate decomposition and manage large waste quantities with controlled temperature and moisture levels. Both methods support sustainable waste management but differ in capacity and operational complexity tailored to residential or industrial-scale composting needs.

Choosing the Right Method for Your Needs

Vermicomposting uses worms to break down organic waste into nutrient-rich castings, ideal for small-scale or indoor setups with kitchen scraps. In-vessel composting accelerates decomposition through controlled temperature and aeration, suitable for larger volumes and commercial applications. Choosing the right method depends on waste type, available space, processing time, and desired output quality.

Vermicomposting Infographic

libterm.com

libterm.com