Traditional plastics, derived from petroleum resources, have long been favored for their durability, versatility, and low production costs, making them ubiquitous in packaging, construction, and consumer goods. However, their resistance to degradation contributes significantly to environmental pollution, posing challenges for waste management and marine ecosystems. Explore the rest of this article to understand the impacts of traditional plastics and discover sustainable alternatives that can benefit your lifestyle.

Table of Comparison

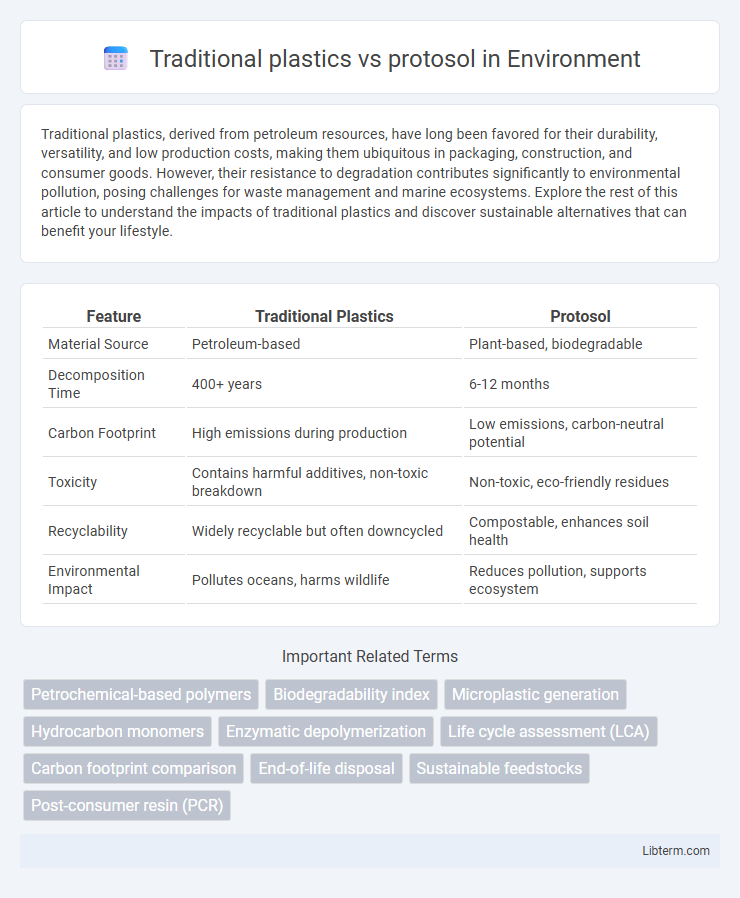

| Feature | Traditional Plastics | Protosol |

|---|---|---|

| Material Source | Petroleum-based | Plant-based, biodegradable |

| Decomposition Time | 400+ years | 6-12 months |

| Carbon Footprint | High emissions during production | Low emissions, carbon-neutral potential |

| Toxicity | Contains harmful additives, non-toxic breakdown | Non-toxic, eco-friendly residues |

| Recyclability | Widely recyclable but often downcycled | Compostable, enhances soil health |

| Environmental Impact | Pollutes oceans, harms wildlife | Reduces pollution, supports ecosystem |

Introduction to Traditional Plastics and Protosol

Traditional plastics, primarily derived from petrochemicals, consist of polymers such as polyethylene, polypropylene, and polystyrene known for their durability and versatility in packaging, construction, and consumer goods. Protosol represents an innovative biodegradable alternative engineered from renewable resources, designed to reduce environmental impact without compromising material performance. The shift from conventional synthetic plastics to biopolymer-based solutions like Protosol is critical in addressing plastic pollution and advancing sustainable materials technology.

Composition and Manufacturing Processes

Traditional plastics primarily consist of petroleum-based polymers such as polyethylene, polypropylene, and polystyrene, produced through polymerization processes like addition or condensation; these manufacturing methods rely heavily on fossil fuels and emit significant greenhouse gases. Protosol, by contrast, is a bio-based material synthesized from renewable resources using a sol-gel process that forms an inorganic-organic hybrid structure, offering enhanced biodegradability and lower environmental impact. The manufacturing of Protosol involves ambient temperature curing and water-based solvents, which reduce energy consumption and toxic byproducts compared to the high-temperature extrusion and molding techniques used for conventional plastics.

Environmental Impact: A Comparative Overview

Traditional plastics, derived from fossil fuels, contribute significantly to environmental pollution through non-biodegradability and toxic chemical leaching, resulting in soil and water contamination. Protosol, a biodegradable alternative, decomposes naturally within months, reducing landfill accumulation and lowering greenhouse gas emissions during degradation. The shift from conventional plastics to Protosol supports sustainable waste management and mitigates long-term ecological damage.

Durability and Lifespan Differences

Traditional plastics typically exhibit durability ranging from 5 to 100 years, depending on the polymer type and environmental exposure, with common materials like polyethylene and polypropylene degrading relatively faster under UV light. Protosol, an innovative biodegradable polymer, offers enhanced lifespan control by breaking down within 12 to 24 months under composting conditions, balancing functional durability with environmental sustainability. This controlled degradation differentiates Protosol from conventional plastics' long persistence, addressing issues of microplastic pollution and landfill accumulation.

Biodegradability and End-of-Life Solutions

Traditional plastics, derived from petrochemicals, are notorious for their slow biodegradability, often persisting in the environment for hundreds of years and contributing significantly to plastic pollution. Protosol, a novel biodegradable material, is engineered to break down rapidly through natural microbial processes, offering a scalable end-of-life solution that reduces landfill accumulation and marine debris. Unlike conventional plastics, protosol supports circular economy principles by enabling composting and efficient waste management, thereby mitigating long-term environmental impact.

Applications across Industries

Traditional plastics dominate sectors like packaging, automotive, and construction due to their durability, moldability, and cost-effectiveness. Protosol, a biodegradable alternative, is gaining traction in medical devices, agriculture, and consumer goods, offering enhanced environmental sustainability without compromising performance. Industry adoption of Protosol accelerates as regulatory pressures and consumer demand for eco-friendly materials increase.

Economic Considerations and Cost Effectiveness

Traditional plastics dominate the market due to low production costs derived from abundant petroleum resources and established manufacturing processes. Protosol, an emerging alternative, offers potential long-term savings through biodegradability and reduced environmental remediation expenses despite higher initial production costs. Cost-effectiveness of protosol improves with increasing scale and regulatory incentives targeting plastic pollution mitigation.

Regulatory and Safety Standards

Traditional plastics are subject to stringent regulatory frameworks such as the Toxic Substances Control Act (TSCA) and the European REACH regulation, which monitor chemical safety, environmental impact, and human health risks. Protosol, being a novel biopolymer, is often evaluated under emerging standards that emphasize biodegradability, non-toxicity, and reduced ecological footprint, aligning with more sustainable safety protocols. Compliance with FDA food-contact regulations and ASTM biodegradability tests positions Protosol as a safer alternative in markets demanding eco-friendly certifications.

Consumer Perceptions and Adoption Trends

Consumer perceptions of traditional plastics often highlight concerns over environmental impact and non-biodegradability, driving a shift toward more sustainable alternatives like Protosol. Adoption trends reveal increasing preference for Protosol due to its biodegradable properties and eco-friendly production methods, aligning with growing demand for green products. Market data indicate that consumers prioritize materials that reduce plastic waste, positioning Protosol as a favorable choice for environmentally conscious buyers.

Future Prospects for Sustainable Materials

Traditional plastics, derived primarily from fossil fuels, pose significant environmental challenges due to their non-biodegradability and high carbon footprint. Protosol, a bio-based, biodegradable alternative, offers promising future prospects for sustainable materials with its potential to reduce plastic pollution and greenhouse gas emissions. Continued innovation and large-scale adoption of Protosol could revolutionize packaging and manufacturing industries, aligning with global sustainability goals and a circular economy.

Traditional plastics Infographic

libterm.com

libterm.com