Aerated static pile composting utilizes forced air to maintain optimal oxygen levels, accelerating the breakdown of organic materials and reducing odors. This method enhances microbial activity, leading to faster, more efficient compost production compared to traditional windrow systems. Discover how this innovative approach can improve Your composting process by reading the full article.

Table of Comparison

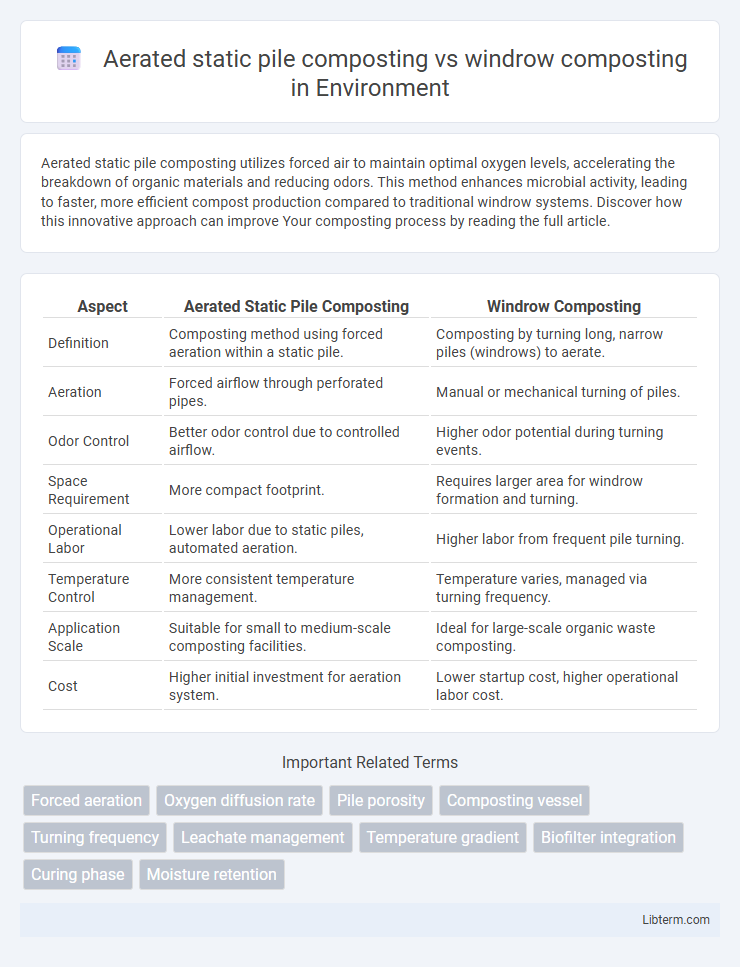

| Aspect | Aerated Static Pile Composting | Windrow Composting |

|---|---|---|

| Definition | Composting method using forced aeration within a static pile. | Composting by turning long, narrow piles (windrows) to aerate. |

| Aeration | Forced airflow through perforated pipes. | Manual or mechanical turning of piles. |

| Odor Control | Better odor control due to controlled airflow. | Higher odor potential during turning events. |

| Space Requirement | More compact footprint. | Requires larger area for windrow formation and turning. |

| Operational Labor | Lower labor due to static piles, automated aeration. | Higher labor from frequent pile turning. |

| Temperature Control | More consistent temperature management. | Temperature varies, managed via turning frequency. |

| Application Scale | Suitable for small to medium-scale composting facilities. | Ideal for large-scale organic waste composting. |

| Cost | Higher initial investment for aeration system. | Lower startup cost, higher operational labor cost. |

Introduction to Composting Methods

Aerated static pile composting uses forced aeration to maintain oxygen levels within a stationary pile, promoting faster decomposition and reducing odor emissions. Windrow composting involves turning elongated piles regularly to introduce oxygen, which supports microbial activity but requires more labor and space. Both methods convert organic waste into nutrient-rich compost but differ in operational efficiency, odor control, and spatial requirements.

Overview of Aerated Static Pile Composting

Aerated static pile composting utilizes forced aeration through a network of pipes beneath the compost pile, enhancing oxygen distribution for efficient microbial activity without requiring frequent turning. This method maintains controlled temperature and moisture levels, accelerating the breakdown of organic materials and reducing odors compared to traditional windrow composting. It is ideal for large-scale operations with consistent waste input, promoting stable decomposition and higher-quality compost output.

Overview of Windrow Composting

Windrow composting involves forming organic materials into long rows or piles that are regularly turned to maintain aerobic conditions, promoting efficient microbial breakdown. This method is widely used in agricultural and municipal waste management due to its simplicity, scalability, and cost-effectiveness, especially for processing large volumes of yard waste, manure, and food scraps. Effective temperature control and oxygen supply in windrow composting accelerate decomposition and minimize odors compared to passive composting methods.

Key Differences Between ASP and Windrow Composting

Aerated Static Pile (ASP) composting uses forced air to maintain oxygen levels and temperature control, enabling faster and more efficient organic matter decomposition than windrow composting, which relies on periodic turning of elongated heaps. ASP systems typically require less labor and space, producing less odor and leachate due to controlled airflow, whereas windrow composting is more suitable for large-scale, lower-cost operations with simpler infrastructure. Temperature monitoring in ASP allows consistent thermophilic conditions, enhancing pathogen reduction compared to the more variable temperature profiles in windrows.

Aeration Techniques: Static vs. Turning

Aerated static pile composting utilizes forced aeration through perforated pipes or blowers to maintain oxygen levels without physically turning the pile, enabling continuous microbial activity and reduced labor. In contrast, windrow composting relies on periodic turning to introduce oxygen, which can be labor-intensive and cause fluctuations in temperature and moisture. The static aeration method offers more controlled oxygen distribution and temperature stability, improving composting efficiency and odor management.

Space and Infrastructure Requirements

Aerated static pile composting requires less space compared to windrow composting due to its vertical pile structure and controlled aeration systems, making it suitable for facilities with limited land availability. Windrow composting demands extensive land area to accommodate long, linear piles with sufficient spacing for machinery access and airflow. Infrastructure for aerated static pile systems includes blowers, piping, and temperature monitoring devices, whereas windrow methods primarily rely on aerating machinery and larger open areas for pile turning.

Labor and Operational Efficiency

Aerated static pile composting requires less manual turning and aeration, significantly reducing labor intensity compared to windrow composting, which demands frequent physical turning to maintain adequate oxygen levels. Operational efficiency is higher in aerated static piles due to controlled airflow systems that optimize microbial activity and composting time, while windrow composting depends heavily on weather conditions and manual intervention, leading to variable processing times. Consequently, aerated static pile systems offer more consistent temperature regulation and moisture control, minimizing labor costs and enhancing overall process reliability.

Compost Quality and Maturity

Aerated static pile composting enhances compost quality and maturity by providing consistent oxygen flow, which accelerates microbial activity and ensures uniform decomposition, resulting in a stable and nutrient-rich end product. Windrow composting, while effective, often leads to uneven aeration and temperature distribution, potentially causing slower maturation and variability in compost quality. The controlled environment of aerated static piles typically produces compost with lower pathogen levels and fewer phytotoxic compounds compared to windrow methods.

Environmental Impact and Emissions

Aerated static pile composting significantly reduces greenhouse gas emissions by providing controlled aeration, minimizing methane production compared to the traditional windrow method, which often leads to higher methane and nitrous oxide emissions due to uneven oxygen distribution. This method also decreases odor and leachate risks by maintaining optimal moisture and temperature levels throughout the composting process. Windrow composting, while cost-effective, typically results in greater environmental pollution due to aerobic and anaerobic zones that promote increased emissions and potential nutrient runoff.

Choosing the Right Composting Method

Aerated static pile composting offers precise oxygen control through forced aeration, enabling faster decomposition and reduced odor, making it ideal for large-scale operations with space constraints. Windrow composting relies on periodic turning for aeration, which is simpler and less costly but requires more land area and labor, suitable for smaller farms or community projects. Selecting the right method depends on factors such as available space, budget, desired processing speed, and odor management needs.

Aerated static pile composting Infographic

libterm.com

libterm.com