Relational databases organize data into tables with rows and columns, making it easy to manage and retrieve structured information efficiently. By using keys to establish relationships between tables, they ensure data integrity and reduce redundancy. Explore the rest of the article to discover how relational databases can optimize your data management strategy.

Table of Comparison

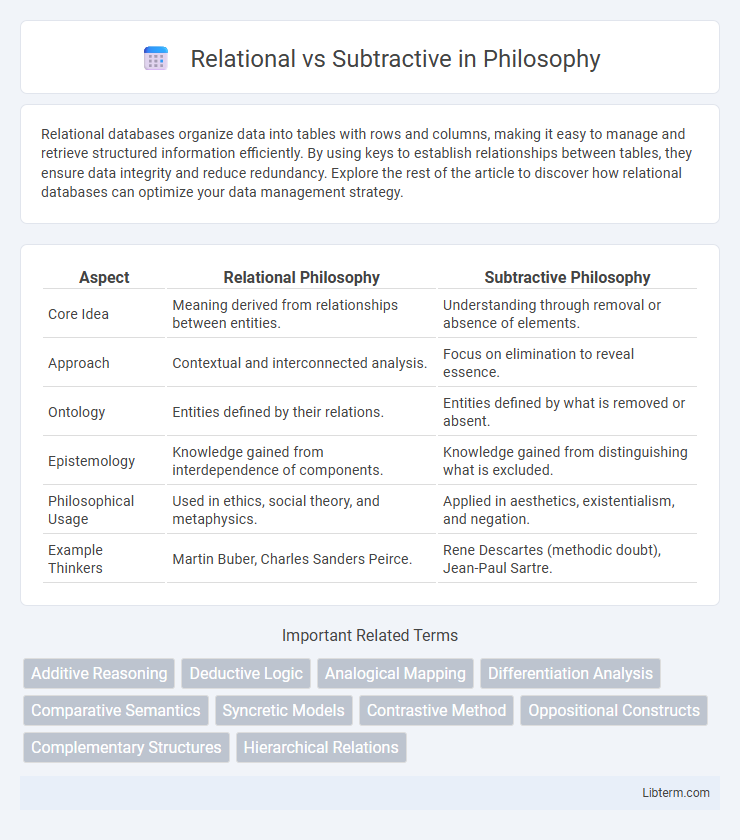

| Aspect | Relational Philosophy | Subtractive Philosophy |

|---|---|---|

| Core Idea | Meaning derived from relationships between entities. | Understanding through removal or absence of elements. |

| Approach | Contextual and interconnected analysis. | Focus on elimination to reveal essence. |

| Ontology | Entities defined by their relations. | Entities defined by what is removed or absent. |

| Epistemology | Knowledge gained from interdependence of components. | Knowledge gained from distinguishing what is excluded. |

| Philosophical Usage | Used in ethics, social theory, and metaphysics. | Applied in aesthetics, existentialism, and negation. |

| Example Thinkers | Martin Buber, Charles Sanders Peirce. | Rene Descartes (methodic doubt), Jean-Paul Sartre. |

Introduction to Relational and Subtractive Approaches

Relational and subtractive approaches represent two distinct methods in data analysis and modeling, with relational approaches focusing on the connections and associations between entities within a dataset. Subtractive methods emphasize the identification and removal of irrelevant or redundant data to enhance clarity and improve computational efficiency. Understanding these foundational differences is critical for selecting appropriate techniques in database management, machine learning, and pattern recognition tasks.

Defining Relational Methods

Relational methods focus on analyzing relationships and structures within data, emphasizing connections between entities rather than isolated attributes, to uncover patterns and associations. These methods use techniques such as graph theory, network analysis, and relational algebra to model complex interactions and dependencies. Defining relational methods involves understanding how data points relate contextually, which can improve decision-making in fields like social network analysis, bioinformatics, and database management.

Understanding Subtractive Techniques

Subtractive techniques in design and manufacturing involve removing material to shape the final product, commonly used in processes like CNC machining, milling, and laser cutting. Understanding subtractive methods requires knowledge of tools, material properties, and precision control to achieve desired dimensions and surface finishes. These techniques contrast with relational or additive methods by focusing on material removal rather than layering or assembling components.

Key Differences Between Relational and Subtractive Models

Relational models focus on establishing and managing relationships between data tables through keys, enabling complex queries and data integrity. Subtractive models, commonly used in design and manufacturing, emphasize removing material or data elements to refine a product or dataset, prioritizing elimination over association. Key differences include the relational model's foundation on data interconnectivity and referential integrity, whereas subtractive models concentrate on reduction processes without inherently maintaining data relationships.

Advantages of Relational Approaches

Relational approaches in data management offer significant advantages by enabling seamless integration and retrieval of complex, interconnected data through structured query languages like SQL. These methods enhance data consistency and integrity via normalization, reducing redundancy and improving storage efficiency. Additionally, relational models support scalability and flexibility, allowing businesses to adapt rapidly to evolving data requirements while ensuring accurate and reliable information access.

Benefits of Subtractive Processes

Subtractive processes offer precise material removal, enabling intricate design details and tight tolerances critical for advanced manufacturing sectors like aerospace and medical devices. These methods reduce waste by using computer-controlled machining to optimize cutting paths and material usage, enhancing overall cost-efficiency. The adaptability of subtractive techniques supports a wide variety of materials, including metals, plastics, and composites, making it a versatile choice for prototyping and small to medium production runs.

Practical Applications of Relational Methods

Relational methods excel in practical applications such as database management, where they enable efficient organization, retrieval, and manipulation of interconnected data sets through structured query languages like SQL. They are pivotal in business intelligence systems, supporting complex data analytics and reporting by modeling real-world relationships between entities. In contrast, subtractive approaches are less suited for relational data contexts, as they focus on elimination or reduction rather than establishing meaningful data connections.

Common Use Cases for Subtractive Techniques

Subtractive techniques are commonly used in manufacturing processes such as CNC machining, laser cutting, and milling to precisely remove material from a workpiece to create complex shapes and components. These methods are ideal for producing high-precision parts in automotive, aerospace, and electronics industries where tight tolerances and intricate details are required. Subtractive manufacturing excels in prototyping and small-to-medium batch production due to its accuracy and ability to work with a wide range of materials including metals, plastics, and composites.

Choosing Between Relational and Subtractive Strategies

Choosing between relational and subtractive strategies depends on the specific goals of data management and analysis. Relational strategies optimize data connectivity and integrity through structured relationships and normalized tables, enhancing query efficiency and scalability. Subtractive strategies streamline datasets by removing redundant or irrelevant information, improving processing speed and reducing storage needs in environments with large, noisy data.

Future Trends in Relational vs Subtractive Approaches

Future trends in relational vs subtractive approaches emphasize the growing integration of advanced additive manufacturing technologies with traditional subtractive methods to enhance precision and material efficiency. Hybrid systems combining CNC machining with 3D printing are increasingly adopted in aerospace and automotive industries for complex, lightweight components. Innovations in AI-driven process optimization are expected to drive faster, more cost-effective production cycles by dynamically switching between relational and subtractive techniques based on design requirements.

Relational Infographic

libterm.com

libterm.com