Viscoelastic materials exhibit both viscous and elastic characteristics when undergoing deformation, allowing them to absorb energy like a fluid and recover shape like a solid. These properties make them essential in industries ranging from automotive to medical devices for vibration damping and shock absorption. Discover how viscoelasticity impacts your daily life and various technologies in the rest of this article.

Table of Comparison

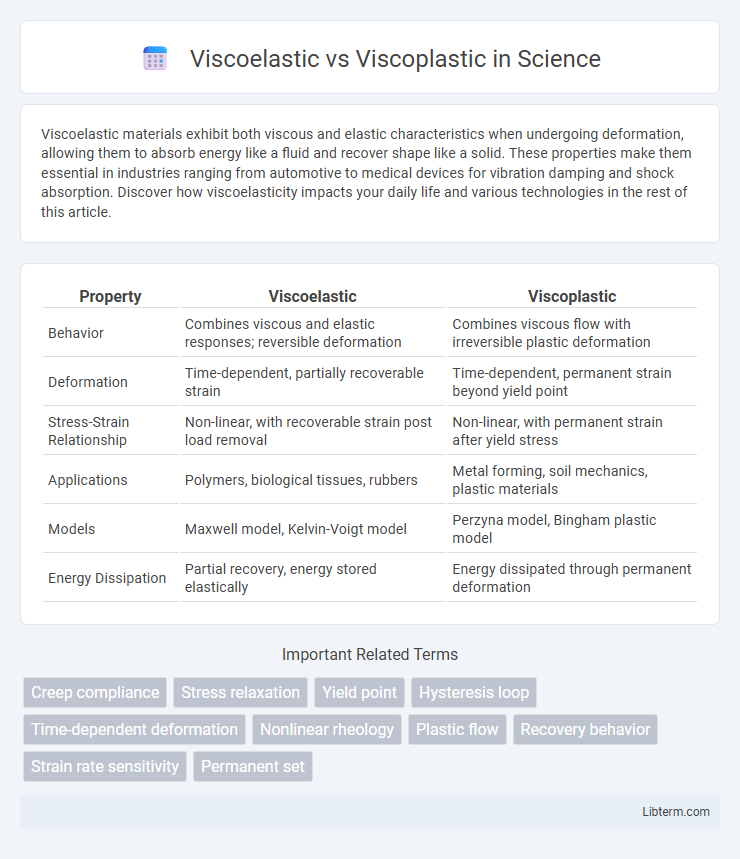

| Property | Viscoelastic | Viscoplastic |

|---|---|---|

| Behavior | Combines viscous and elastic responses; reversible deformation | Combines viscous flow with irreversible plastic deformation |

| Deformation | Time-dependent, partially recoverable strain | Time-dependent, permanent strain beyond yield point |

| Stress-Strain Relationship | Non-linear, with recoverable strain post load removal | Non-linear, with permanent strain after yield stress |

| Applications | Polymers, biological tissues, rubbers | Metal forming, soil mechanics, plastic materials |

| Models | Maxwell model, Kelvin-Voigt model | Perzyna model, Bingham plastic model |

| Energy Dissipation | Partial recovery, energy stored elastically | Energy dissipated through permanent deformation |

Introduction to Viscoelastic and Viscoplastic Materials

Viscoelastic materials exhibit both viscous and elastic characteristics when undergoing deformation, allowing them to store and dissipate energy through time-dependent strain. Viscoplastic materials combine viscous flow and plastic deformation, displaying permanent shape change after a yield stress is surpassed. Understanding these behaviors is critical in applications such as polymers, metals, and biological tissues, where stress-strain responses impact material performance and durability.

Fundamental Definitions: Viscoelasticity vs Viscoplasticity

Viscoelasticity refers to a material property where deformation exhibits both viscous and elastic characteristics, allowing the material to recover its original shape over time after stress removal. Viscoplasticity, however, involves irreversible deformation where the material behaves as a viscous fluid after yielding, without recovering its initial shape. The fundamental difference lies in the reversible strain recovery in viscoelastic materials versus permanent strain in viscoplastic materials.

Key Differences in Material Behavior

Viscoelastic materials exhibit time-dependent strain, combining elastic recovery with viscous flow, allowing them to deform under stress and gradually return to their original shape. Viscoplastic materials demonstrate irreversible deformation after a yield stress, flowing like a viscous material but maintaining permanent shape changes. The key difference lies in viscoelasticity's reversible strain with delayed recovery, whereas viscoplasticity involves permanent deformation once the yield threshold is exceeded.

Stress-Strain Relationships: Viscoelastic vs Viscoplastic

Viscoelastic materials exhibit time-dependent stress-strain relationships characterized by reversible deformation combining both elastic and viscous behavior, where strain recovers after stress removal. Viscoplastic materials demonstrate permanent deformation with a yield stress threshold, showing no strain recovery once the stress exceeds this limit. Stress relaxation and creep are prominent in viscoelasticity, whereas viscoplasticity involves irreversible flow beyond the yield point.

Time-Dependent Properties Compared

Viscoelastic materials exhibit time-dependent strain recovery, showing both elastic and viscous behavior that allows deformation to partially reverse after stress removal. Viscoplastic materials demonstrate irreversible deformation over time under stress, combining viscous flow with a permanent plastic strain once the yield stress is exceeded. The key difference lies in viscoelasticity's recoverable time-dependent deformation versus viscoplasticity's permanent, time-dependent flow beyond the yield point.

Common Applications of Viscoelastic Materials

Viscoelastic materials are widely used in applications requiring energy dissipation and shock absorption, such as automotive engine mounts, vibration dampers, and protective sports gear. These materials exhibit time-dependent strain, allowing for reversible deformation under stress, making them ideal for medical devices like prosthetics and orthodontic aligners. In contrast, viscoplastic materials undergo permanent deformation, finding use in metal forming and plastic flow processes where irrecoverable shape change is essential.

Practical Uses of Viscoplastic Materials

Viscoplastic materials, characterized by irreversible deformation under stress, are essential in applications requiring permanent shape change, such as metal forming, soil mechanics, and crash energy absorption in automotive safety. Their ability to undergo plastic flow while exhibiting time-dependent behavior makes them ideal for manufacturing processes like extrusion and forging, where controlled deformation enhances product quality. These properties also facilitate designing materials that can dissipate energy and resist permanent damage under cyclic loading conditions.

Experimental Methods for Characterizing Each Type

Viscoelastic materials are characterized using dynamic mechanical analysis (DMA), stress relaxation tests, and creep experiments to assess their time-dependent strain under applied stress and their ability to recover shape. Viscoplastic materials require experimental methods like yield stress measurements, uniaxial compression or tension tests, and cyclic loading to determine irreversible deformation and flow behavior beyond the elastic limit. Rheometers equipped for controlled stress or strain loading provide critical data differentiating viscoelastic and viscoplastic responses by capturing both recoverable and permanent deformations under varying conditions.

Factors Influencing Viscoelastic and Viscoplastic Properties

Temperature significantly impacts viscoelastic properties by altering molecular mobility and relaxation times, while stress magnitude influences viscoplastic behavior by initiating irreversible deformation. Material microstructure, including polymer chain length and crosslink density, plays a crucial role in determining both viscoelastic stiffness and viscoplastic yield strength. Time-dependent loading conditions also affect viscoelastic creep and stress relaxation, in contrast to viscoplastic strain accumulation under sustained high stresses.

Choosing the Right Material for Engineering Applications

Viscoelastic materials exhibit time-dependent strain with partial recovery upon unloading, making them ideal for applications requiring energy dissipation and damping, such as vibration isolators and shock absorbers. Viscoplastic materials undergo irreversible deformation under stress, providing permanent strain useful in applications like metal forming and structural components that must absorb impact without failure. Selecting the right material depends on balancing the need for recoverable deformation in viscoelastic materials against the permanent strain behavior of viscoplastic materials, guided by application-specific stress, strain rate, and durability requirements.

Viscoelastic Infographic

libterm.com

libterm.com