Efficiently managing cuts is essential for maintaining the integrity and precision of your project, whether in woodworking, metalworking, or crafting. Proper techniques and tools ensure clean edges and reduce material waste, saving you time and money. Discover expert tips and strategies in the rest of this article to master the art of cutting effectively.

Table of Comparison

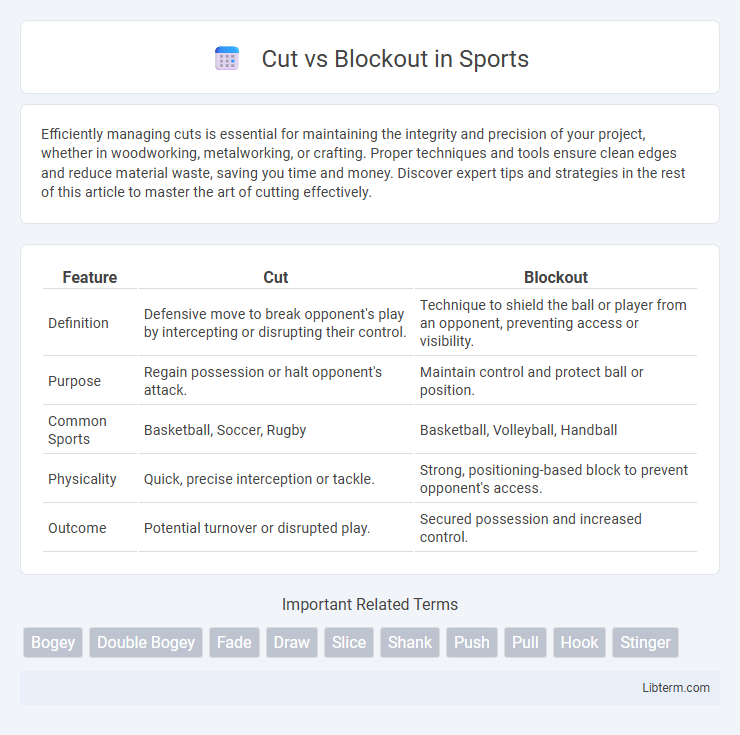

| Feature | Cut | Blockout |

|---|---|---|

| Definition | Defensive move to break opponent's play by intercepting or disrupting their control. | Technique to shield the ball or player from an opponent, preventing access or visibility. |

| Purpose | Regain possession or halt opponent's attack. | Maintain control and protect ball or position. |

| Common Sports | Basketball, Soccer, Rugby | Basketball, Volleyball, Handball |

| Physicality | Quick, precise interception or tackle. | Strong, positioning-based block to prevent opponent's access. |

| Outcome | Potential turnover or disrupted play. | Secured possession and increased control. |

Understanding Cut and Blockout: Key Differences

Cut refers to a technique in graphic design and printing where a specific shape or portion of material is precisely removed or trimmed to create a desired outline or form. Blockout involves applying an opaque layer or material to cover and prevent visibility of underlying elements, often used in signage or packaging to enhance contrast and readability. The key difference lies in cut altering the material's shape by removal, while blockout covers the material without changing its physical boundaries.

The Importance of Precision in Cut and Blockout Processes

Precision in the cut and blockout processes is critical to ensuring accuracy and efficiency in manufacturing and construction. Accurate cuts minimize material waste and reduce the risk of rework, while precise blockouts guarantee proper fitting and alignment of components, preventing structural issues. Advanced measuring tools and computer-aided design (CAD) software enhance precision, contributing to higher quality outcomes and cost savings.

Tools and Techniques for Achieving Accurate Cuts

Precision tools such as utility knives, rotary cutters, and cutting mats are essential for achieving accurate cuts in both Cut and Blockout techniques. Using sharp blades combined with metal rulers or straight edges ensures straight, clean lines while minimizing material waste. For Blockout applications, layering techniques and heat-assisted tools enhance edge sharpness and durability, providing optimal coverage and fit.

Blockout Methods: Materials and Best Practices

Blockout methods primarily utilize materials such as polyethylene, polyurethane, and acrylics to achieve effective masking and protection in manufacturing and painting processes. Best practices emphasize selecting blockout materials based on surface compatibility, curing times, and environmental resistance to ensure clean edges and easy removal without residue. Proper application techniques, including even spreading and secure adhesion, enhance durability and prevent infiltration, optimizing overall performance in surface preparation.

Cut vs Blockout: Applications in Various Industries

Cut materials offer precise shaping and customization, making them ideal for applications in automotive design, aerospace engineering, and tailored packaging solutions. Blockout materials provide complete opacity and durability, commonly used in advertising banners, privacy screens, and outdoor signage to prevent light transmission and ensure content visibility. Both Cut and Blockout are essential across industries requiring specific visual, protective, or structural properties for products and displays.

Common Challenges in Cutting and Blocking Out

Cutting and blocking out processes commonly face challenges such as imprecise measurements leading to misalignment and waste. Material inconsistency can cause uneven cuts or incomplete blockouts, affecting the final product quality. Ensuring the right tools and consistent technique is critical to overcoming issues like edge chipping and inadequate adhesion in blocking out.

Enhancing Efficiency: Tips for Streamlining Cut and Blockout Workflows

Cut and blockout workflows can be streamlined by integrating automated software solutions that optimize material usage and minimize waste, leading to faster processing times. Implementing project management tools tailored for cut and blockout tasks helps coordinate teams and track progress, reducing bottlenecks and errors. Standardizing measurement and marking techniques further enhances accuracy and consistency, improving overall efficiency in construction and manufacturing projects.

Safety Protocols for Cut and Blockout Operations

Cut and blockout operations require strict safety protocols to prevent accidents and ensure worker protection. In cut operations, personal protective equipment (PPE) such as gloves, goggles, and cut-resistant clothing is critical to guard against sharp tools and flying debris. Blockout procedures demand securing the workspace with proper lockout/tagout systems and barricades to prevent unauthorized access and maintain machine isolation during maintenance or installation tasks.

Quality Control: Ensuring Consistency in Cut and Blockout Results

Quality control in cut and blockout processes centers on maintaining uniformity in dimensions, edges, and surface treatments to meet strict industry standards. Implementing precise measurement tools and standardized procedures minimizes variability and defects, ensuring reliable and consistent outcomes. Regular inspections and calibration of equipment enhance repeatability, reducing material waste and improving overall product quality.

Future Trends: Innovations in Cutting and Blockout Technologies

Cutting and blockout technologies are evolving rapidly with innovations such as laser precision cutting and advanced polymer blockout films that enhance durability and environmental resistance. Future trends indicate increased use of AI-driven automation to optimize cutting accuracy and reduce waste in blockout applications. Integration of smart materials that adjust opacity or texture dynamically is expected to revolutionize traditional blockout methods, offering greater control and functionality.

Cut Infographic

libterm.com

libterm.com