Leading edge technology drives innovation by pushing boundaries and setting new standards in various industries. It empowers businesses to stay competitive and adapt swiftly to market changes, enhancing overall efficiency and growth. Explore the rest of this article to discover how adopting leading edge solutions can transform your operations.

Table of Comparison

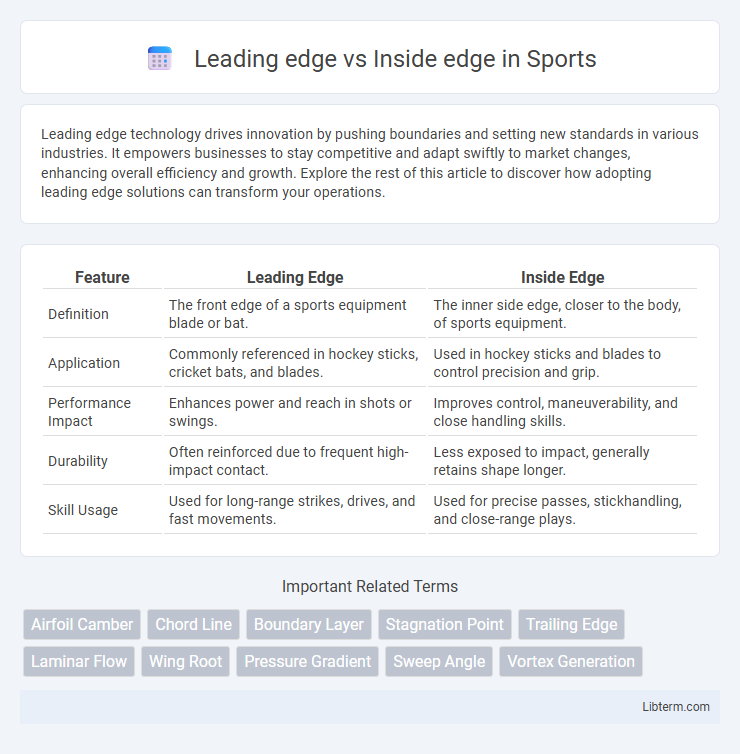

| Feature | Leading Edge | Inside Edge |

|---|---|---|

| Definition | The front edge of a sports equipment blade or bat. | The inner side edge, closer to the body, of sports equipment. |

| Application | Commonly referenced in hockey sticks, cricket bats, and blades. | Used in hockey sticks and blades to control precision and grip. |

| Performance Impact | Enhances power and reach in shots or swings. | Improves control, maneuverability, and close handling skills. |

| Durability | Often reinforced due to frequent high-impact contact. | Less exposed to impact, generally retains shape longer. |

| Skill Usage | Used for long-range strikes, drives, and fast movements. | Used for precise passes, stickhandling, and close-range plays. |

Introduction: Understanding Leading Edge vs Inside Edge

Leading edge refers to the front part of an object or surface that first contacts the surrounding medium, often critical in aerodynamics and engineering for optimizing performance and reducing drag. Inside edge denotes the interior boundary or edge of a structure, frequently relevant in design contexts such as blade technology and sports equipment for enhancing control and precision. Differentiating between leading edge and inside edge is essential for applications requiring aerodynamic efficiency and structural functionality.

Defining Leading Edge and Inside Edge

The leading edge refers to the front part of an object, particularly in aerodynamics or sports like cricket, where it interacts first with the airflow or ball. The inside edge is the edge closest to the body or central axis, commonly used in cricket or skiing contexts to describe the part of the bat or ski facing inward. Understanding the difference between leading edge and inside edge is crucial for optimizing performance and technique in fields such as aviation, sports, and engineering.

Key Differences Between Leading Edge and Inside Edge

Leading edge refers to the foremost part of an object, such as an aircraft wing or turbine blade, that first meets the airflow, significantly influencing aerodynamic performance and efficiency. Inside edge, often related to sports or gear design, denotes the inner margin closest to the body's centerline, affecting control and stability in movements or equipment fit. Key differences between leading edge and inside edge hinge on their positional context and functional impact, with the leading edge critical for initial contact and airflow management, while the inside edge primarily contributes to balance and precision in handling.

Importance of Edge Selection in Performance

Choosing between the leading edge and inside edge of a skate blade significantly impacts overall performance and maneuverability. The leading edge allows for sharper turns and quicker acceleration, while the inside edge offers better stability and control during glides. Proper edge selection enhances speed, precision, and efficiency, crucial for competitive skating success.

Applications Across Various Industries

Leading edge technology drives innovation in industries such as aerospace, healthcare, and automotive by enabling faster data processing, enhanced machine learning, and real-time analytics. Inside edge solutions optimize operational efficiency in retail, finance, and manufacturing through improved edge computing protocols, localized data storage, and reduced latency. Both approaches play critical roles in advancing IoT infrastructure, enabling smart city implementations, and supporting autonomous systems across diverse sectors.

Technological Innovations in Edge Design

Leading edge and inside edge innovations drive aerodynamic efficiency and control in modern airfoils and turbine blades. Advanced materials like carbon composites enable lighter, stronger leading edges, reducing drag and improving performance, while inside edge designs incorporate sensor integration for real-time monitoring and adaptive response. Computational fluid dynamics (CFD) and additive manufacturing further optimize edge geometries, enhancing turbulence management and structural resilience in aerospace and renewable energy sectors.

Advantages and Disadvantages of Each Edge Type

Leading edge blades offer superior aerodynamic efficiency by reducing drag and enhancing lift, resulting in better overall performance in applications like turbines and propellers. However, they are more susceptible to erosion and impact damage due to their exposure, requiring frequent maintenance. Inside edge designs provide improved structural strength and easier maintenance access but may experience higher turbulence and reduced aerodynamic efficiency compared to leading edge configurations.

Factors Influencing Edge Choice

Leading edge choice depends heavily on aircraft design, speed, and aerodynamic goals, as it affects airflow control and lift generation during takeoff and landing. Inside edge selection focuses on structural strength, ease of maintenance, and integration with internal wing components like slats or flaps. Engineers weigh factors such as drag reduction, wing loading distribution, and manufacturing complexity to optimize performance and safety outcomes.

Real-World Examples of Leading and Inside Edges

Leading edge technology in solar panels, such as bifacial modules used by Tesla's Solar Roof, captures sunlight on both sides, enhancing energy output in real-world conditions. Inside edge innovation is evident in Apple's M1 chip, which integrates CPU, GPU, and RAM on a single die, delivering superior performance and efficiency within compact hardware. Companies like Boeing utilize leading edge composite materials in aircraft wings for reduced weight and increased fuel efficiency, while smartphone manufacturers like Samsung optimize inside edge software algorithms to improve camera performance and battery life.

Conclusion: Choosing the Right Edge for Your Needs

Selecting between leading edge and inside edge technologies depends on your specific application and performance requirements. Leading edge offers innovative features and higher adaptability for cutting-edge solutions, while inside edge provides stability and cost-effectiveness for traditional setups. Evaluating factors such as scalability, integration, and long-term maintenance ensures the optimal choice for your operational needs.

Leading edge Infographic

libterm.com

libterm.com