A pin is a small, pointed object used to fasten or secure items such as fabric, paper, or hair. Common in sewing, crafts, and everyday organization, pins come in various shapes and materials to suit different purposes. Explore the article to discover the diverse types of pins and their practical uses for your projects.

Table of Comparison

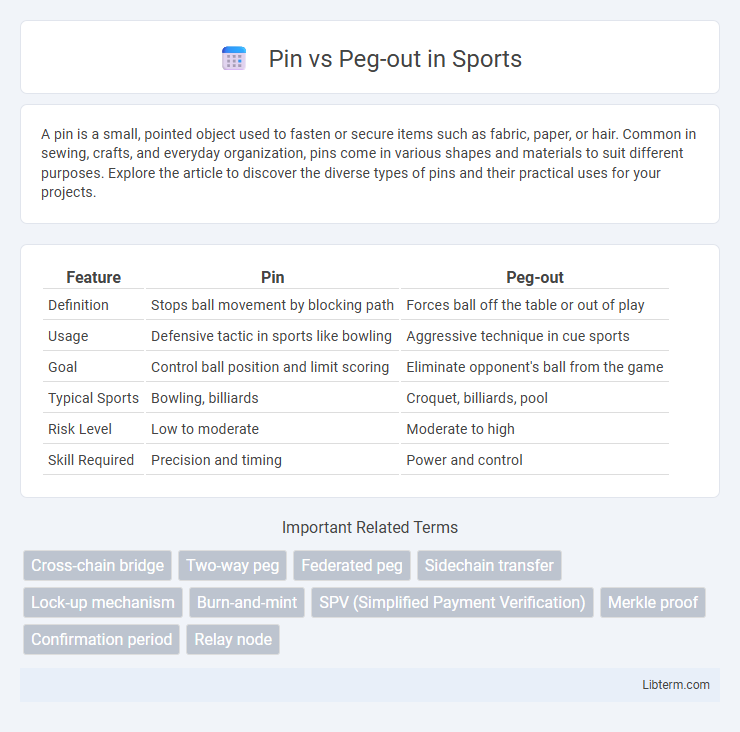

| Feature | Pin | Peg-out |

|---|---|---|

| Definition | Stops ball movement by blocking path | Forces ball off the table or out of play |

| Usage | Defensive tactic in sports like bowling | Aggressive technique in cue sports |

| Goal | Control ball position and limit scoring | Eliminate opponent's ball from the game |

| Typical Sports | Bowling, billiards | Croquet, billiards, pool |

| Risk Level | Low to moderate | Moderate to high |

| Skill Required | Precision and timing | Power and control |

Definition of Pin vs Peg-out

A pin refers to a physical electrical contact point on an electronic component or circuit board used for making connections. Peg-out is the process of assigning and documenting the exact physical positions and designations of pins on a printed circuit board (PCB) layout to ensure proper connectivity and assembly. Pin defines the component's interface, while peg-out details the spatial arrangement of these pins in the PCB design.

Historical Context in Crypto Transactions

Pin and peg-out mechanisms emerged during the early development of blockchain interoperability and cross-chain transactions, addressing the need for secure asset transfers between distinct networks. Pinning refers to the process of anchoring a blockchain's state or checkpoints onto another trusted chain to enhance security and finality, commonly seen in sidechains or layer-2 solutions. Peg-out involves moving assets out of a pegged or wrapped environment back to the original blockchain, a critical step in protocols like Bitcoin's sidechains and wrapped tokens on Ethereum, highlighting the evolving complexity of blockchain composability and trust assumptions over time.

Key Differences Between Pin and Peg-out

Pin refers to a physical electrical contact on a component or PCB used for connectivity, while peg-out is the CAD process of creating the initial footprint outline for that pin on a PCB layout. Pins represent the actual hardware terminals enabling signal or power transmission, whereas peg-outs are temporary CAD markers guiding the placement of these pins during design. The key difference lies in pins being tangible elements in hardware, while peg-outs serve as reference points in PCB design software prior to finalizing the board layout.

The Role of Pin and Peg-out in Blockchain

Pins in blockchain act as cryptographic proofs that anchor transaction batches to a public ledger, enhancing security and verifying data integrity. Peg-outs enable transferring assets from a sidechain back to the main blockchain, ensuring interoperability and fund accessibility. Both mechanisms play crucial roles in maintaining trust, enabling secure cross-chain communication and safeguarding asset movement.

Use Cases for Each Mechanism

Pins provide versatile connection points in electronic circuits, enabling flexible interfacing with various components, sensors, or external devices, commonly used in microcontrollers and integrated circuits. Peg-outs serve as mechanical fixtures on printed circuit boards (PCBs), ensuring precise alignment during assembly or facilitating mounting in enclosures, widely applied in manufacturing processes and device housing. Selecting pins optimizes signal routing and electrical connectivity, while peg-outs enhance mechanical stability and alignment accuracy in complex electronic assemblies.

Security Implications and Considerations

Pin and Peg-out mechanisms differ significantly in security implications; pins provide fixed, hardware-based access points ensuring consistent physical connectivity, while peg-outs offer removable or temporary interfaces prone to unauthorized access risks. Security considerations for pins involve robust physical protection against tampering and electromagnetic interference, whereas peg-outs demand strict access controls, encrypted communication, and monitoring to prevent data leakage and unauthorized device connections. Organizations must assess the threat landscape and implement layered security protocols tailored to the chosen interface to mitigate vulnerabilities effectively.

Technical Process: How Pin Works

Pins function as physical connectors in electronic circuits, facilitating the flow of electrical signals between components or devices. Each pin is designed with specific electrical characteristics such as voltage rating, current capacity, and contact resistance, ensuring reliable signal transmission. In technical processes, pins are soldered onto printed circuit boards (PCBs) or housed within connectors, enabling secure mechanical and electrical interfacing essential for circuit functionality.

Technical Process: How Peg-out Works

Peg-out is a crucial step in the semiconductor manufacturing process where individual chips are separated from the wafer after completion of circuit fabrication. During peg-out, small holes or pegs on the chip's edge align with the mechanical pins on the sawing equipment to ensure precise and damage-free dicing. This mechanical alignment facilitates accurate placement and separation, preserving chip integrity for subsequent packaging and testing stages.

Challenges Facing Pin and Peg-out

Pin and Peg-out signals often face challenges related to signal integrity and timing accuracy due to their critical roles in circuit interfacing and testing processes. Pin assignments can become problematic when overcrowding or improper labeling causes misrouting and electrical interference, leading to malfunction or hardware damage. Peg-out signals encounter difficulties in maintaining consistent external connectivity and reliability, especially in high-density or complex PCB layouts where mechanical stress and environmental factors can degrade contact quality.

Future Trends and Innovations

Pin and Peg-out technologies are evolving with advancements in semiconductor packaging and high-speed testing to enhance signal integrity and minimize parasitic effects. Emerging trends include the integration of pogo pin connectors with adaptive impedance matching and the development of micro-needle probe cards for peg-out, supporting higher frequency testing for 5G and AI applications. Innovations in materials and nano-fabrication techniques are driving increased durability and precision, enabling more reliable and scalable test solutions in next-generation electronics manufacturing.

Pin Infographic

libterm.com

libterm.com