Additive manufacturing revolutionizes production by building objects layer by layer, enabling complex designs and reducing material waste. This technology offers unprecedented customization and rapid prototyping, transforming industries from aerospace to healthcare. Discover how additive processes can enhance your manufacturing capabilities by reading the full article.

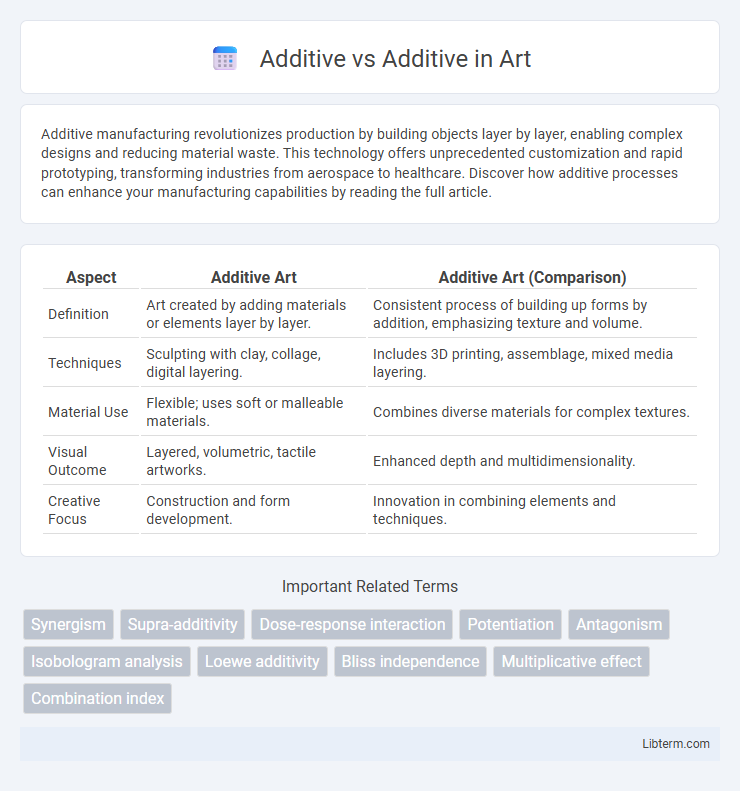

Table of Comparison

| Aspect | Additive Art | Additive Art (Comparison) |

|---|---|---|

| Definition | Art created by adding materials or elements layer by layer. | Consistent process of building up forms by addition, emphasizing texture and volume. |

| Techniques | Sculpting with clay, collage, digital layering. | Includes 3D printing, assemblage, mixed media layering. |

| Material Use | Flexible; uses soft or malleable materials. | Combines diverse materials for complex textures. |

| Visual Outcome | Layered, volumetric, tactile artworks. | Enhanced depth and multidimensionality. |

| Creative Focus | Construction and form development. | Innovation in combining elements and techniques. |

Understanding the Basics: What Does "Additive vs Additive" Mean?

Additive vs Additive refers to comparing two additive processes or materials that combine elements to enhance properties or effects, commonly used in fields like manufacturing and chemistry. This concept involves analyzing how different additives interact, influence composition, and impact the final product's performance or characteristics. Understanding these interactions helps optimize formulations or processes for improved efficiency, durability, or functionality.

Types of Additives in Industry: A Comparative Overview

Additives in industry are broadly categorized into functional additives, processing additives, and performance additives, each serving distinct roles such as enhancing product stability, aiding manufacturing processes, or improving end-use properties. Functional additives include antioxidants, UV stabilizers, and antimicrobial agents that protect materials from degradation. Processing additives like plasticizers and lubricants facilitate easier manufacturing, while performance additives such as fillers and flame retardants enhance material strength, durability, and safety.

Chemical Additives vs Biological Additives: Key Differences

Chemical additives are synthetic compounds introduced in products to enhance shelf life, texture, or flavor through chemical reactions. Biological additives consist of natural microorganisms or enzymes that improve product quality by promoting fermentation, preserving nutrients, or accelerating digestion. Key differences lie in their sources--chemical additives are man-made chemicals, whereas biological additives are living organisms or derivatives that support natural processes.

Performance Comparison: Efficiency of Different Additives

Performance comparison between different additives reveals significant variations in efficiency based on their chemical composition and intended application. For instance, polymer-based additives enhance fuel combustion efficiency by reducing friction and wear, while metal-based additives improve thermal conductivity and oxidation resistance. Evaluating parameters such as viscosity index improvement, corrosion inhibition, and emission reduction provides a comprehensive understanding of each additive's effectiveness in industrial or automotive systems.

Safety Considerations: Evaluating Additive Impacts

Evaluating additive impacts requires thorough safety assessments to identify potential chemical interactions and toxicological effects, ensuring consumer protection. Regulatory guidelines and standardized testing protocols play a critical role in assessing the risks associated with various additives in food, pharmaceuticals, and industrial products. Risk management strategies prioritize minimizing exposure to harmful substances while maintaining product efficacy and compliance with safety standards.

Environmental Implications: Which Additive Is Greener?

Comparing the environmental implications of additives reveals that bio-based additives sourced from renewable materials generally have a lower carbon footprint and reduce dependency on fossil fuels compared to petroleum-based additives. Additives such as natural antioxidants and biodegradable plasticizers minimize toxic emissions and enhance product recyclability, contributing to a greener lifecycle. Evaluating factors like biodegradability, toxicity, and energy consumption during production helps determine the overall ecological impact, with bio-additives often emerging as the more sustainable option.

Cost Analysis: Budgeting for Different Additives

Cost analysis of additives requires evaluating the price per unit, compatibility with existing formulations, and impact on production efficiency. Budgeting should account for the raw material cost, potential savings from enhanced product performance, and any required process modifications. Selecting additives involves balancing upfront expenses against long-term benefits such as durability, effectiveness, and regulatory compliance.

Regulatory Standards for Various Additives

Regulatory standards for additives vary significantly depending on the type and application, with agencies like the FDA, EFSA, and JECFA setting stringent limits on permissible concentrations to ensure consumer safety. Food additives such as preservatives, colorants, and flavor enhancers must comply with specific Codex Alimentarius guidelines and undergo safety assessments based on toxicological data and acceptable daily intake (ADI) levels. Industrial additives like plasticizers and lubricants are regulated under chemical safety frameworks such as REACH in the EU and TSCA in the US, mandating thorough risk evaluations and environmental impact studies.

Application-Specific Additive Selection

Application-specific additive selection depends on the desired material properties and end-use performance criteria, such as thermal stability, mechanical strength, or chemical resistance. Tailoring additives such as plasticizers, stabilizers, or fillers to the target application ensures optimized compatibility with the polymer matrix and enhances product durability. Precise additive formulation improves manufacturing efficiency and meets industry standards for sectors like automotive, aerospace, and electronics.

Future Trends in Additive Technologies

Future trends in additive technologies emphasize advancements in multi-material 3D printing and improvements in speed and precision, driving broader industrial adoption. Innovations in metal additive manufacturing and biofabrication are enabling production of complex components with enhanced mechanical properties and biocompatibility. Integration of AI and machine learning optimizes additive processes, reducing waste and accelerating design-to-production cycles in aerospace, automotive, and healthcare sectors.

Additive Infographic

libterm.com

libterm.com