Assemblage is an artistic technique involving the creation of three-dimensional compositions by combining various found objects and materials. This form of art enhances visual storytelling by integrating textures, colors, and forms that evoke unique emotional responses. Discover how assemblage can transform ordinary items into captivating works of art as you explore the rest of this article.

Table of Comparison

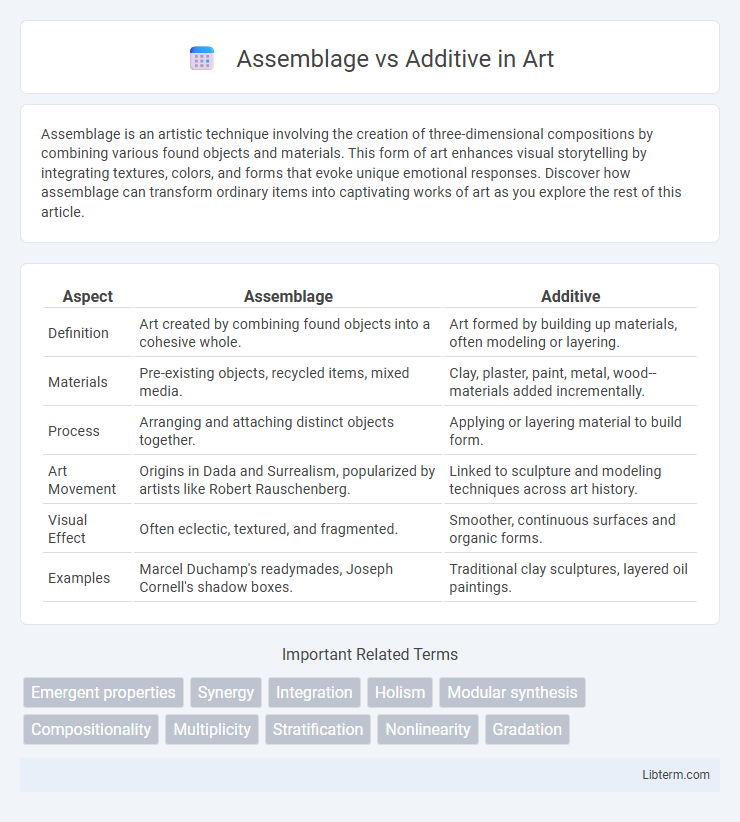

| Aspect | Assemblage | Additive |

|---|---|---|

| Definition | Art created by combining found objects into a cohesive whole. | Art formed by building up materials, often modeling or layering. |

| Materials | Pre-existing objects, recycled items, mixed media. | Clay, plaster, paint, metal, wood--materials added incrementally. |

| Process | Arranging and attaching distinct objects together. | Applying or layering material to build form. |

| Art Movement | Origins in Dada and Surrealism, popularized by artists like Robert Rauschenberg. | Linked to sculpture and modeling techniques across art history. |

| Visual Effect | Often eclectic, textured, and fragmented. | Smoother, continuous surfaces and organic forms. |

| Examples | Marcel Duchamp's readymades, Joseph Cornell's shadow boxes. | Traditional clay sculptures, layered oil paintings. |

Understanding Assemblage and Additive Approaches

Assemblage approaches emphasize the dynamic interrelations and emergent properties of heterogeneous elements within a system, highlighting how components connect and influence each other in complex networks. Additive approaches focus on the cumulative effects of individual parts, often quantifying and summing discrete contributions to understand overall structure or function. Understanding these methodologies involves recognizing assemblage as a framework for interaction and emergence, while additive methods prioritize aggregation and measurable impacts of single elements.

Key Differences Between Assemblage and Additive Methods

Assemblage methods involve creating products by joining or assembling pre-made components, emphasizing mechanical connections and modular construction. Additive methods build objects layer-by-layer from raw materials, often through 3D printing or similar technologies, allowing for complex geometries and reduced material waste. Key differences lie in the manufacturing process, with assemblage focusing on combining parts and additive concentrating on material deposition and fabrication.

Historical Background of Assemblage vs Additive

Assemblage art, emerging prominently in the early 20th century with pioneers like Pablo Picasso and Marcel Duchamp, involves creating three-dimensional compositions from found objects, emphasizing texture and physicality. Additive techniques, rooted in classical sculpture traditions, entail building forms by adding and shaping materials such as clay or metal, tracing back to ancient civilizations including Mesopotamia and Greece. The historical evolution of assemblage reflects a shift from traditional additive methods toward a conceptual and experimental approach in modern and contemporary art.

Applications in Art and Design

Assemblage art integrates diverse found objects to create textured, multidimensional compositions, emphasizing tactile and visual contrasts ideal for expressive, mixed-media installations. Additive techniques build forms layer by layer, commonly used in 3D printing and sculpture for precise control over shape and detail, enabling innovative, complex designs in contemporary art. Both methods influence modern design by offering unique approaches to materiality and spatial interaction, with assemblage fostering organic creativity and additive processes supporting digital fabrication scalability.

Assemblage in Architecture: Concepts and Examples

Assemblage in architecture involves the combination of diverse materials, forms, and spatial elements to create complex structures that emphasize heterogeneity and interconnectivity. Unlike additive construction, which builds progressively by layering, assemblage encourages non-linear composition and adaptive reuse, fostering innovative design solutions. Notable examples include the Centre Pompidou in Paris, where exposed structural components highlight an assemblage approach, and the High Line in New York City, which transforms industrial remnants into dynamic public spaces.

Additive Manufacturing: Principles and Innovations

Additive manufacturing revolutionizes production by building objects layer by layer directly from digital models, enabling complex geometries and material efficiency unattainable with traditional assemblage methods. Innovations in additive manufacturing include multi-material printing, real-time process monitoring, and advanced feedstock materials, driving customization and reducing waste in industries such as aerospace and healthcare. Principles such as precise layer adhesion, controlled thermal management, and integration of design for additive manufacturing (DfAM) optimize performance and structural integrity of printed parts.

Advantages and Challenges of Assemblage Techniques

Assemblage techniques in manufacturing offer advantages such as enhanced structural integrity and the ability to combine diverse materials, leading to innovative product designs with improved functionality. These methods also enable precise alignment and joining of complex components, facilitating customization and scalability in production processes. However, assemblage faces challenges including the need for specialized tools, potential increases in assembly time, and difficulties in managing cyclic loads or thermal expansion between different joined materials.

Benefits and Limitations of Additive Processes

Additive manufacturing offers significant benefits such as design flexibility, material efficiency, and rapid prototyping, enabling complex geometries that traditional assemblage processes cannot achieve. However, limitations include slower production speeds for large volumes, material constraints, and higher initial costs for equipment and materials compared to conventional assembly methods. Balancing these factors is crucial for industries leveraging additive processes to optimize performance and cost-effectiveness.

Comparing Assemblage and Additive in Industrial Contexts

Assemblage in industrial contexts involves combining diverse components or materials to create a complex product, emphasizing integration and functionality, whereas additive manufacturing focuses on layer-by-layer material deposition to build parts directly from digital models, enhancing design flexibility and reducing waste. Assemblage processes typically require extensive assembly lines and human or robotic labor for joining parts, while additive techniques leverage 3D printing technologies to produce intricate geometries with minimal tooling. Comparing these methods reveals that assemblage suits mass production of standardized products, whereas additive manufacturing excels in rapid prototyping and customized, low-volume manufacturing.

Future Trends: Integrating Assemblage and Additive Approaches

Future trends in manufacturing highlight the integration of assemblage and additive approaches to enhance production efficiency and customization. Combining additive manufacturing's precision layering with assemblage's modular construction allows for scalable, sustainable, and flexible design solutions. Advanced materials and AI-driven automation are expected to further streamline this hybrid process, enabling rapid prototyping and on-demand manufacturing across industries.

Assemblage Infographic

libterm.com

libterm.com