Binders and fillers play crucial roles in manufacturing and material formulation by enhancing product stability and improving texture. Binders ensure particles adhere together for structural integrity, while fillers add bulk and reduce production costs without compromising quality. Explore the rest of the article to learn how these components impact your product's performance and application.

Table of Comparison

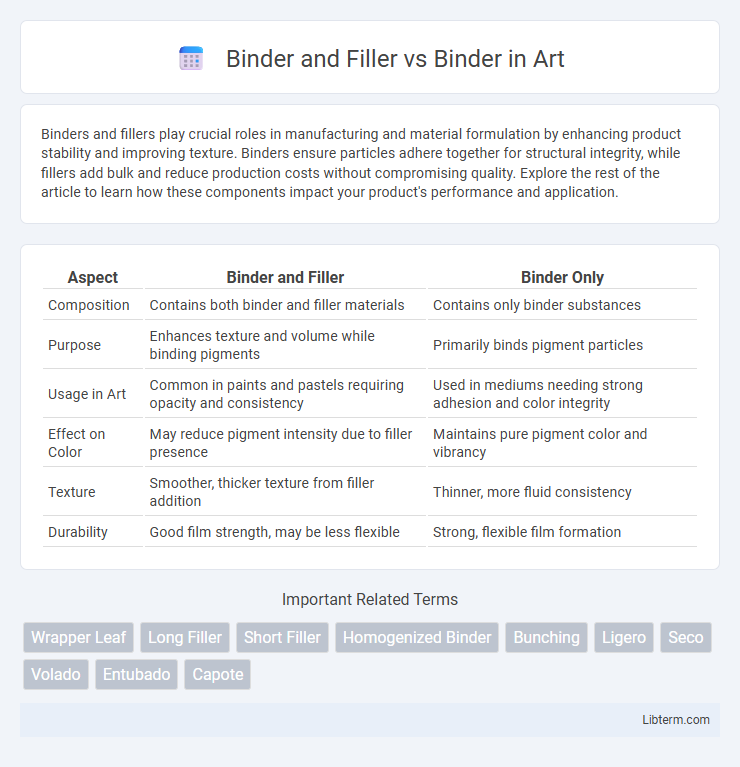

| Aspect | Binder and Filler | Binder Only |

|---|---|---|

| Composition | Contains both binder and filler materials | Contains only binder substances |

| Purpose | Enhances texture and volume while binding pigments | Primarily binds pigment particles |

| Usage in Art | Common in paints and pastels requiring opacity and consistency | Used in mediums needing strong adhesion and color integrity |

| Effect on Color | May reduce pigment intensity due to filler presence | Maintains pure pigment color and vibrancy |

| Texture | Smoother, thicker texture from filler addition | Thinner, more fluid consistency |

| Durability | Good film strength, may be less flexible | Strong, flexible film formation |

Understanding Binder and Filler: Key Definitions

Binder and filler are essential components in pharmaceutical formulations, with the binder acting as a cohesive agent that ensures the powder particles adhere together, providing mechanical strength to tablets. Fillers, also known as diluents, increase the bulk volume of the formulation without affecting its therapeutic activity, making the dosage form easier to handle and manufacture. Understanding the distinct roles and properties of binders and fillers is crucial for optimizing tablet stability, dissolution, and bioavailability.

The Role of Binder in Various Industries

The role of binder in various industries is crucial for combining materials to enhance product strength, cohesion, and durability. In construction and manufacturing, binders such as cement or adhesives provide structural integrity by holding aggregates or components together, while fillers primarily improve texture, reduce costs, and add bulk without significantly contributing to strength. Industries like pharmaceuticals, paints, and plastics rely on binders to ensure uniformity and stability in formulations, whereas fillers serve as secondary agents that modify physical properties or improve processability.

What is a Filler? Functions and Types

A filler is an inert substance added to materials to improve properties, reduce cost, or enhance processing. Common functions of fillers include increasing bulk, improving mechanical strength, enhancing texture, and affecting thermal or electrical conductivity. Types of fillers vary from natural powders like calcium carbonate and talc to synthetic materials such as silica, glass beads, and polymeric microspheres.

Binder and Filler: Essential Differences

Binder and filler differ fundamentally in their functions within composite materials: binders act as adhesives that hold particles together, providing structural integrity, while fillers primarily enhance properties like texture, volume, and cost-efficiency without contributing significant bonding strength. Binders often consist of polymers, resins, or cementitious compounds that chemically or physically bond components, whereas fillers include inert substances like sand, talc, or calcium carbonate that modify density and mechanical behavior. Understanding these essential differences is crucial in material design to optimize performance, durability, and economic value based on application requirements.

Applications of Binder Alone vs Binder and Filler Combination

Binders alone are widely used in pharmaceutical formulations, adhesives, and paint production to provide cohesion and structural integrity, ensuring particle adhesion and improved mechanical strength. The combination of binder and filler enhances this effect by adding bulk, reducing production costs, and improving the texture, durability, and volume of the final product in industries such as construction, cosmetics, and food processing. Applications using both binder and filler benefit from improved compressibility and reduced brittleness, making them ideal for tablets, molded plastics, and composite materials.

Performance Impact: Binder with vs without Filler

Binders with fillers improve mechanical strength, thermal stability, and cost-efficiency by adding materials such as calcium carbonate or silica that enhance composite properties. Binders without fillers generally offer higher purity and better adhesive properties but can lack structural reinforcement, leading to reduced durability under stress. The performance impact shows that incorporating fillers into binders optimizes composite resilience and longevity, making them ideal for heavy-duty applications.

Cost Analysis: Binder Only vs Binder and Filler Blends

Cost analysis reveals that binder-only formulations typically incur higher material expenses due to the exclusive use of specialized binders, whereas binder and filler blends reduce overall costs by incorporating inexpensive fillers that dilute the binder content. Fillers such as calcium carbonate, talc, or clay lower raw material prices and improve processing efficiency without significantly compromising mechanical properties or adhesion strength. Optimizing the ratio of binder to filler enables manufacturers to balance performance requirements with cost-effectiveness, making binder-filler blends an economically advantageous choice in applications like adhesives, coatings, and composites.

Material Properties: Effects of Filler Addition

The addition of fillers to binders significantly enhances the composite's mechanical strength, thermal stability, and dimensional stability by improving load distribution and reducing shrinkage. Fillers influence the material's viscosity and curing behavior, which affects processing and final performance characteristics such as hardness and impact resistance. Optimizing the filler type, size, and concentration tailors the binder's properties for specific applications, ensuring improved durability and cost-efficiency.

Choosing the Right Mixture: Factors to Consider

Choosing the right mixture between binder and filler versus binder alone depends on the desired texture, strength, and cost-efficiency of the final product. Binders provide adhesive properties essential for cohesion in materials like construction composites and adhesives, while fillers can enhance volume, reduce costs, and influence properties like weight and durability. Key factors to consider include the application's mechanical requirements, environmental exposure, and compatibility with other components to ensure optimal performance and longevity.

Future Trends in Binder and Filler Technology

Future trends in binder and filler technology emphasize the development of eco-friendly and sustainable materials, integrating bio-based binders with advanced nano-fillers to enhance mechanical strength and thermal stability. Innovations include smart binders capable of self-healing and responsive behavior, alongside optimized filler dispersion techniques to improve composite performance in automotive and construction industries. Research is accelerating toward multifunctional binder-filler systems that reduce environmental impact while maximizing durability and cost efficiency.

Binder and Filler Infographic

libterm.com

libterm.com