Screen printing offers vibrant, long-lasting designs by pushing ink through a mesh stencil onto various surfaces, making it ideal for apparel, posters, and promotional items. This technique ensures sharp, vivid colors and durability, perfect for both small and large production runs. Discover how screen printing can elevate Your brand's visibility in the rest of this article.

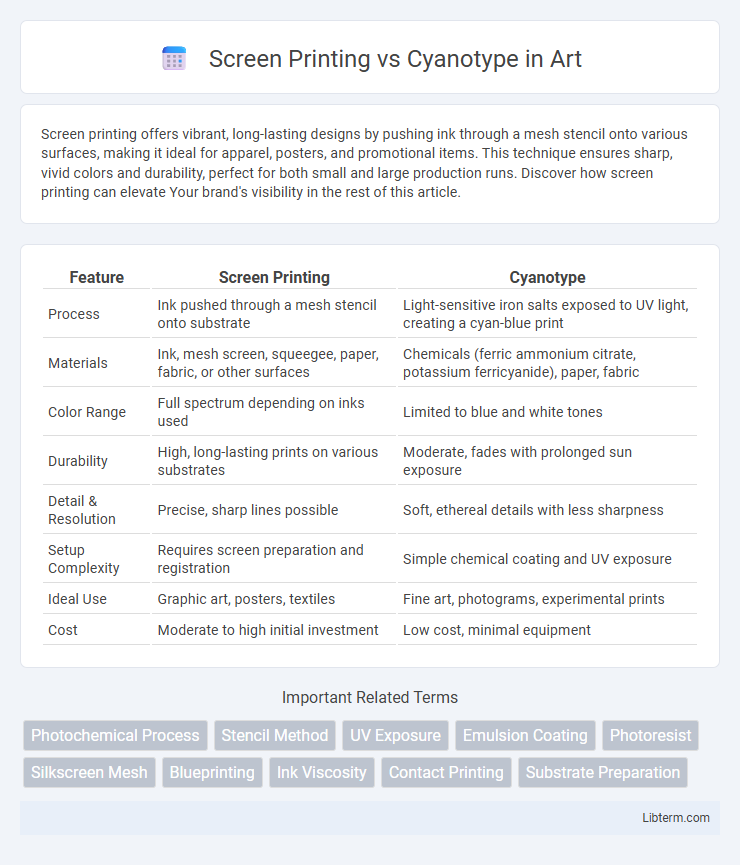

Table of Comparison

| Feature | Screen Printing | Cyanotype |

|---|---|---|

| Process | Ink pushed through a mesh stencil onto substrate | Light-sensitive iron salts exposed to UV light, creating a cyan-blue print |

| Materials | Ink, mesh screen, squeegee, paper, fabric, or other surfaces | Chemicals (ferric ammonium citrate, potassium ferricyanide), paper, fabric |

| Color Range | Full spectrum depending on inks used | Limited to blue and white tones |

| Durability | High, long-lasting prints on various substrates | Moderate, fades with prolonged sun exposure |

| Detail & Resolution | Precise, sharp lines possible | Soft, ethereal details with less sharpness |

| Setup Complexity | Requires screen preparation and registration | Simple chemical coating and UV exposure |

| Ideal Use | Graphic art, posters, textiles | Fine art, photograms, experimental prints |

| Cost | Moderate to high initial investment | Low cost, minimal equipment |

Introduction to Screen Printing and Cyanotype

Screen printing is a versatile printing technique that uses a mesh screen, ink, and a squeegee to transfer designs onto various surfaces like fabric, paper, and plastic. Cyanotype is a photographic printing process that creates distinctive blueprints by exposing treated paper to UV light through a negative or objects. Both methods offer unique artistic results, with screen printing excelling in vibrant, multi-colored designs and cyanotype producing ethereal, monochromatic images.

Historical Background of Both Techniques

Screen printing originated in ancient China during the Song Dynasty, with modern techniques refined in early 20th-century America for commercial and artistic applications. Cyanotype was invented in 1842 by Sir John Herschel as a photographic printing process using iron salts to create distinctive blueprints, becoming popular for scientific and artistic purposes in the late 19th century. Both methods represent pioneering innovations in image reproduction, with screen printing evolving from stencil-based techniques and cyanotype stemming from early photochemical discoveries.

Core Principles: How Screen Printing Works

Screen printing operates by forcing ink through a stencil on a fine mesh screen, creating a precise and vibrant image on various surfaces. The core principle involves blocking out areas on the screen where ink should not pass, allowing ink to transfer only in the desired design regions. This method offers exceptional control over color layering and opacity, making it ideal for high-quality, repeatable prints on textiles, paper, and other materials.

Core Principles: How Cyanotype Works

Cyanotype is a photographic printing process that uses a mixture of ferric ammonium citrate and potassium ferricyanide, which reacts to ultraviolet light to create a cyan-blue print. Exposure to UV light reduces the ferric ions to ferrous ions, triggering an insoluble blue pigment called Prussian blue to form on the paper or fabric. Unlike screen printing, which relies on stencils and ink pushed through a mesh screen, cyanotype produces images through a chemical light-sensitive reaction, making it ideal for capturing detailed negative images and botanicals.

Materials and Equipment Required

Screen printing requires a mesh screen, squeegee, stencil or emulsion, and specialized inks designed for fabric or paper printing, while cyanotype relies on light-sensitive chemicals such as ferric ammonium citrate and potassium ferricyanide, along with UV light exposure and contact printing materials like translucent negatives or natural objects. Screen printing demands a sturdy frame and a controlled workspace for precise ink application, whereas cyanotype needs trays for chemical coatings, a drying area, and sunlight or UV lamps for consistent exposure. The materials in screen printing offer vibrant, durable prints suitable for mass production, while cyanotype provides unique, blue-toned photographic prints with a more experimental and organic process.

Visual Results: Colors, Textures, and Detail

Screen printing delivers vibrant, opaque colors with sharp edges and consistent texture, ideal for bold graphic designs and fine detail reproduction. Cyanotype produces a characteristic blue-toned image with soft gradients and organic textures, offering unique, vintage aesthetics but less color variety and precision. The choice hinges on desired visual impact: screen printing excels in color richness and detail clarity, while cyanotype emphasizes tonal depth and artistic texture.

Durability and Longevity of Prints

Screen printing produces prints with high durability due to its use of thick layers of ink that resist fading and wear over time, making it ideal for long-lasting applications on textiles and posters. Cyanotype prints, while appreciated for their unique blue tones and aesthetic, are more susceptible to fading when exposed to light and environmental factors, limiting their longevity. For projects requiring enduring and robust prints, screen printing is the preferred method, whereas cyanotype suits artistic or decorative purposes where longevity is less critical.

Artistic Applications and Popular Uses

Screen printing excels in producing vibrant, precise images on textiles, posters, and merchandise, making it a favorite for commercial art and fashion design. Cyanotype, known for its characteristic blue hues and photographic quality, is popular in experimental art, educational projects, and botanical prints. Artists choose screen printing for mass production and sharp detail, while cyanotype appeals for its unique aesthetic and hands-on, chemical-based process.

Environmental Impact and Sustainability

Screen printing typically uses plastisol inks containing PVC and phthalates, which are harmful to the environment and require chemical solvents for cleanup, increasing ecological footprint. Cyanotype employs iron-based, non-toxic chemicals and water for development, producing minimal waste and biodegradable byproducts, making it a more sustainable and eco-friendly process. The environmental impact of cyanotype is significantly lower, positioning it as a greener alternative to traditional screen printing methods.

Choosing the Right Technique for Your Project

Screen printing offers vibrant, durable prints ideal for bold designs on textiles and posters, while cyanotype produces unique, blue-toned images perfect for artistic and photographic projects. Consider factors like material compatibility, color complexity, production volume, and desired aesthetic when selecting between these techniques. Choosing screen printing suits high-volume, multi-color projects, whereas cyanotype is better for low-volume, handcrafted, and experimental works.

Screen Printing Infographic

libterm.com

libterm.com