Embossing enhances materials by creating raised designs that add texture and visual interest, commonly used in paper, leather, and metal products. This technique not only improves the aesthetic appeal but also increases the tactile experience, making your items stand out with a professional and elegant finish. Explore the rest of the article to learn how embossing can transform your projects with unique and lasting impressions.

Table of Comparison

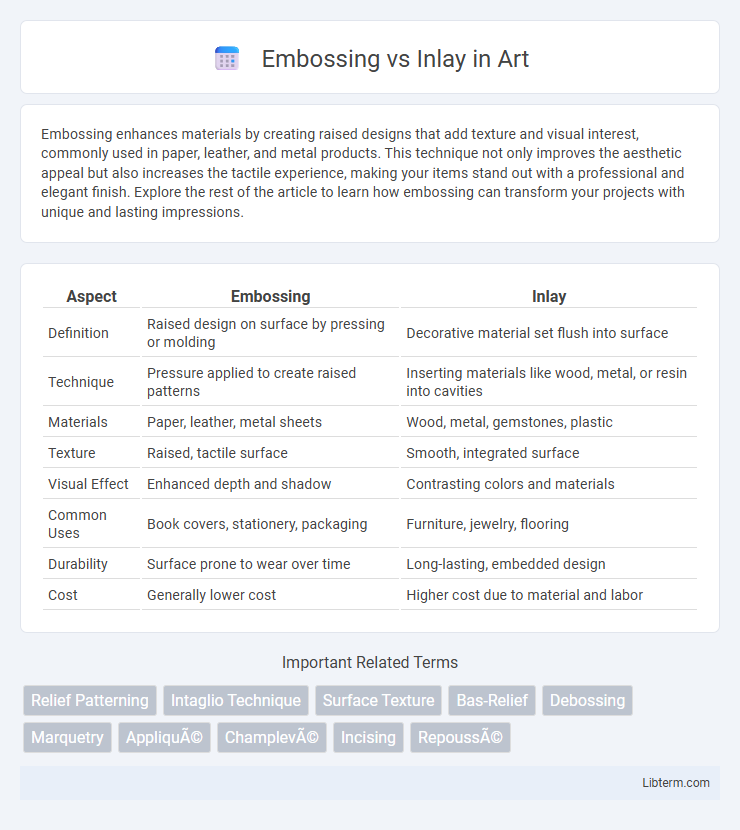

| Aspect | Embossing | Inlay |

|---|---|---|

| Definition | Raised design on surface by pressing or molding | Decorative material set flush into surface |

| Technique | Pressure applied to create raised patterns | Inserting materials like wood, metal, or resin into cavities |

| Materials | Paper, leather, metal sheets | Wood, metal, gemstones, plastic |

| Texture | Raised, tactile surface | Smooth, integrated surface |

| Visual Effect | Enhanced depth and shadow | Contrasting colors and materials |

| Common Uses | Book covers, stationery, packaging | Furniture, jewelry, flooring |

| Durability | Surface prone to wear over time | Long-lasting, embedded design |

| Cost | Generally lower cost | Higher cost due to material and labor |

Introduction to Embossing and Inlay

Embossing is a printing technique that creates a raised design on paper or other materials by pressing them between two engraved plates, adding texture and a tactile dimension. Inlay involves embedding a contrasting material or color into a recessed area of a surface, producing a smooth and often multicolored decorative effect. Both methods enhance visual appeal and tactile interest, commonly used in luxury packaging, book covers, and stationery.

Defining Embossing: Techniques and Applications

Embossing is a technique that creates raised designs on materials such as paper, leather, or metal by pressing a shaped die into the surface, enhancing texture and visual appeal. Common applications include stationery, packaging, and book covers, where tactile elements add sophistication and brand distinction. This method differs from inlay, which involves embedding contrasting materials into a surface for decorative effect rather than merely raising the texture.

Understanding Inlay: Process and Uses

Inlay involves embedding materials such as wood, metal, or shell into a base surface to create intricate, decorative patterns that are flush with the surface. This process requires precision cutting of both the inlay pieces and the base material to ensure a seamless fit, often used in furniture, musical instruments, and fine jewelry for enhancing aesthetic appeal. Unlike embossing, which raises the design above the surface, inlay maintains a smooth texture while adding contrasting colors and materials for visual depth.

Key Differences Between Embossing and Inlay

Embossing creates a raised design on a surface by pressing a pattern into paper, leather, or metal, enhancing texture and visual depth without adding color or materials. Inlay involves embedding different materials, such as wood, metal, or resin, into a base surface to form a contrasting, flush design, resulting in both color and texture variation. The main difference lies in embossing's reliance on surface deformation versus inlay's incorporation of additional materials for decorative effect.

Material Compatibility: Embossing vs Inlay

Embossing works effectively on softer materials like leather, paper, and thin metals, creating raised patterns by pressing a design into the surface. Inlay involves embedding pieces of contrasting material such as wood, metal, or resin into a base substrate, requiring a precise cutout for a flush and durable finish. Material compatibility for embossing depends on pliability and thickness, while inlay demands hardness and depth tolerance to securely hold the inserted elements.

Visual and Tactile Effects: Aesthetic Comparison

Embossing raises designs above the surface, creating a three-dimensional texture that enhances visual depth and tactile engagement, often used in luxury packaging and stationery for a sophisticated look. Inlay involves embedding materials into a recessed area, resulting in a smooth, flush finish with contrasting colors or textures that offer a refined, polished aesthetic. Both techniques provide distinct visual and tactile effects, with embossing emphasizing raised patterns and inlay highlighting smooth, integrated designs.

Durability and Longevity: Which Lasts Longer?

Embossing creates a raised design on materials by pressing them from underneath, providing subtle texture that can wear down over time with heavy use or exposure to elements. Inlay involves embedding materials such as metals, wood, or resin into the surface, resulting in a design that is more integrated and resistant to abrasion and fading. Typically, inlay offers superior durability and longevity compared to embossing, making it a preferred choice for items requiring enduring visual appeal.

Cost Considerations: Embossing vs Inlay

Embossing generally incurs lower costs than inlay due to simpler production processes and fewer materials required, making it ideal for high-volume, budget-sensitive projects. Inlay techniques involve embedding different materials into the base surface, increasing labor, material expenses, and overall complexity, which drives up costs. Choosing between embossing and inlay depends on budget constraints and desired visual impact, as inlays offer richer detail but at a premium price.

Choosing the Right Method for Your Project

Embossing creates raised designs on materials by pressing them with a patterned die, adding texture and elegance ideal for paper, leather, and metal projects. Inlay involves embedding different materials or colors into a base surface for a contrasting, detailed effect often used in woodworking and jewelry. Choosing the right method depends on project goals, material compatibility, desired aesthetic, and durability requirements.

Conclusion: Embossing or Inlay—Which Is Better?

Embossing offers a textured, raised effect ideal for adding tactile dimension and elegance, while inlay creates a smooth, flush finish with contrasting colors or materials for intricate designs. The choice between embossing and inlay depends on the desired aesthetic, material compatibility, and application purpose. For projects prioritizing subtlety and color contrast, inlay is preferred, whereas embossing suits designs emphasizing texture and depth.

Embossing Infographic

libterm.com

libterm.com