Planographic printing is a method where the image and non-image areas are on the same plane, relying on the immiscibility of oil and water for ink adhesion. This technique, commonly used in lithography, enables high-quality reproduction of fine details and smooth tonal variations. Discover how planographic printing can enhance Your creative projects by exploring the rest of this article.

Table of Comparison

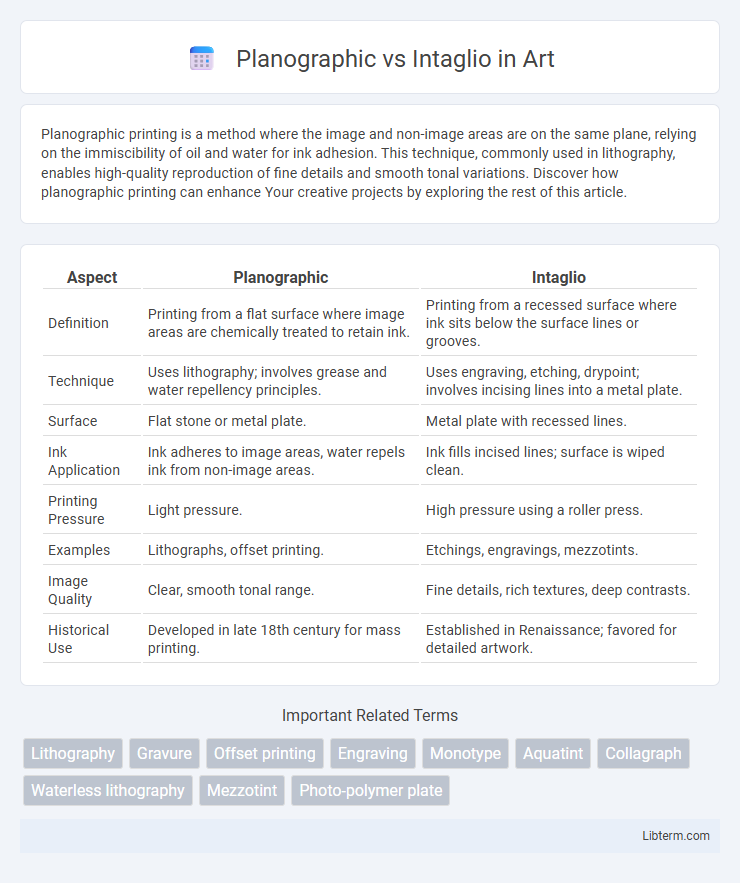

| Aspect | Planographic | Intaglio |

|---|---|---|

| Definition | Printing from a flat surface where image areas are chemically treated to retain ink. | Printing from a recessed surface where ink sits below the surface lines or grooves. |

| Technique | Uses lithography; involves grease and water repellency principles. | Uses engraving, etching, drypoint; involves incising lines into a metal plate. |

| Surface | Flat stone or metal plate. | Metal plate with recessed lines. |

| Ink Application | Ink adheres to image areas, water repels ink from non-image areas. | Ink fills incised lines; surface is wiped clean. |

| Printing Pressure | Light pressure. | High pressure using a roller press. |

| Examples | Lithographs, offset printing. | Etchings, engravings, mezzotints. |

| Image Quality | Clear, smooth tonal range. | Fine details, rich textures, deep contrasts. |

| Historical Use | Developed in late 18th century for mass printing. | Established in Renaissance; favored for detailed artwork. |

Introduction to Printmaking Techniques

Planographic printmaking relies on the principle that oil and water do not mix, using a flat surface such as lithography stones or metal plates where the image area is chemically treated to hold ink while the non-image area repels it. Intaglio printmaking involves engraving or etching into metal plates, where ink settles into recessed lines or textures and is then transferred to paper under high pressure, producing fine details and rich tonal variations. Both techniques serve as fundamental methods in printmaking, each offering distinct textures and artistic effects that have shaped the evolution of the medium.

Understanding Planographic Printing

Planographic printing relies on the principle of oil and water repelling each other, where the image and non-image areas coexist on the same flat surface. Lithography is the primary example of planographic printing, using a smooth limestone or metal plate, making it ideal for producing high-quality images with fine detail and rich tonal range. This process contrasts with intaglio printing, which involves engraving or etching below the surface, emphasizing the importance of surface chemistry in planographic techniques.

Key Features of Intaglio Printing

Intaglio printing is characterized by its engraved or etched recessed lines on a metal plate, which hold the ink and transfer detailed, high-resolution images onto paper. It produces rich, textured prints with deep tonal variations and fine line work, commonly used for currency, stamps, and fine art. Unlike planographic techniques, intaglio requires high pressure to push paper into the ink-filled grooves, resulting in a distinctive embossed effect on the final print.

Historical Development of Planographic Methods

Planographic printing methods originated in the late 18th century with Alois Senefelder's invention of lithography in 1796, revolutionizing image reproduction by exploiting the immiscibility of oil and water on a flat stone surface. Unlike intaglio, which relies on incised lines, planographic techniques maintain a smooth printing plate that holds ink only on treated non-image areas, enabling faster and more cost-effective mass production during the 19th century. The historical development of planographic methods includes significant refinements such as offset lithography in the early 20th century, which enhanced print quality and efficiency, firmly establishing planography as a dominant commercial printing process.

Evolution and Importance of Intaglio Processes

Intaglio printmaking evolved from early engraving techniques into complex processes like etching, mezzotint, and aquatint, allowing artists to achieve finer details and richer tonal variations than planographic methods. The importance of intaglio lies in its ability to produce high-quality prints with deep lines that hold ink, offering superior texture and depth compared to the flat surface of planographic prints such as lithography. This technical advancement made intaglio essential in producing detailed artworks, currency, and secure documents, marking a significant evolution in printmaking history.

Core Differences: Planographic vs Intaglio

Planographic printing relies on a flat printing surface where ink adheres to the image area due to chemical differences, while intaglio printing uses a recessed surface where ink fills engraved lines or grooves. In planographic methods such as lithography, the image and non-image areas coexist on the same plane, but intaglio involves etching or engraving grooves that hold the ink below the surface level. The core difference lies in how ink is applied and transferred: planographic prints use surface tension and repellents, whereas intaglio prints depend on ink trapped in incised areas to produce detailed, textured impressions.

Materials and Tools Used in Each Method

Planographic printmaking relies on a flat surface where images are created using oil-based inks repelling water, typically utilizing lithographic stones or aluminum plates as materials. Tools for planographic techniques include greasy crayons or tusche for drawing, along with rollers and brushes for ink application. Intaglio printmaking involves incising designs into metal plates, often made of copper or zinc, employing specialized tools such as burins, etching needles, and acid baths for creating grooves that hold ink.

Common Artistic Applications

Planographic printing, commonly used in lithography, excels in producing detailed, flat-surface images ideal for posters, fine art prints, and commercial artwork. Intaglio printing, including techniques like etching and engraving, is favored for its ability to create rich textures and intricate line work, making it popular for banknotes, high-end art prints, and detailed illustrations. Both methods serve distinct artistic purposes, with planographic techniques emphasizing smooth gradations and intaglio providing depth and tactile quality in artistic applications.

Advantages and Limitations of Each Technique

Planographic printing, such as lithography, enables high-speed production with vivid color and fine detail, benefiting from a flat printing surface that simplifies plate preparation. However, it struggles with reproducing deep textures and requires careful chemical treatments to maintain image integrity. Intaglio printing excels in producing rich textures and intricate lines by engraving beneath the plate surface, offering superior durability for high-quality, detailed prints but involves more complex and time-consuming plate preparation and higher production costs.

Choosing the Right Printmaking Method

Choosing between planographic and intaglio printmaking depends on desired texture and detail. Planographic methods like lithography use a flat surface for smooth, subtle tonal variations, ideal for delicate and expressive imagery. Intaglio techniques, including etching and engraving, create rich, precise lines and deep contrasts by printing from incised surfaces, making them suited for intricate detail and strong visual impact.

Planographic Infographic

libterm.com

libterm.com