Enamelware offers durable and stylish cookware with a smooth, glass-like coating that resists rust and scratches, making it ideal for everyday use. Its vibrant colors and easy-to-clean surface enhance both kitchen aesthetics and functionality. Discover more about how enamelware can transform your cooking experience in the rest of this article.

Table of Comparison

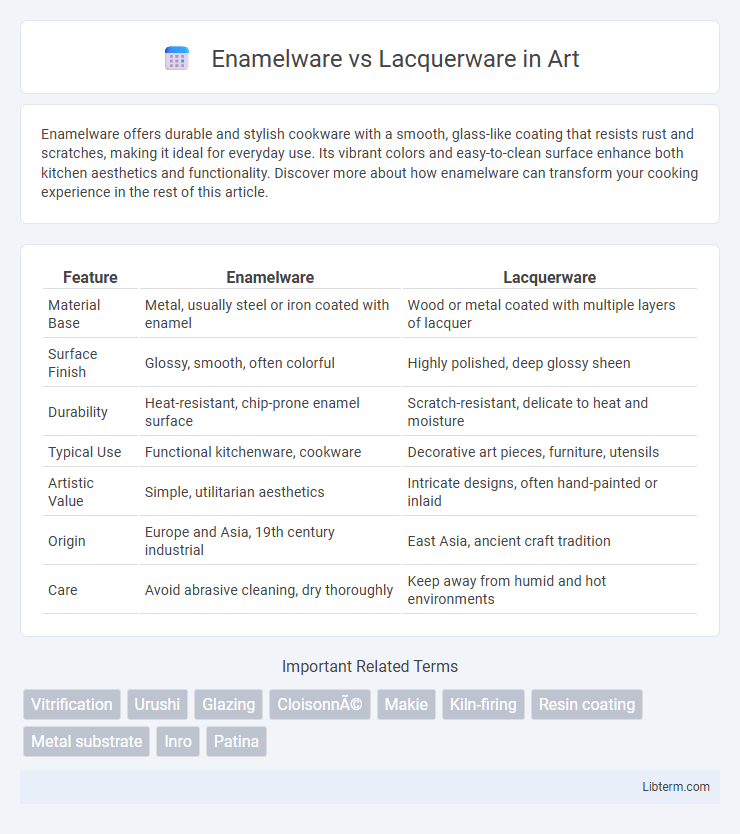

| Feature | Enamelware | Lacquerware |

|---|---|---|

| Material Base | Metal, usually steel or iron coated with enamel | Wood or metal coated with multiple layers of lacquer |

| Surface Finish | Glossy, smooth, often colorful | Highly polished, deep glossy sheen |

| Durability | Heat-resistant, chip-prone enamel surface | Scratch-resistant, delicate to heat and moisture |

| Typical Use | Functional kitchenware, cookware | Decorative art pieces, furniture, utensils |

| Artistic Value | Simple, utilitarian aesthetics | Intricate designs, often hand-painted or inlaid |

| Origin | Europe and Asia, 19th century industrial | East Asia, ancient craft tradition |

| Care | Avoid abrasive cleaning, dry thoroughly | Keep away from humid and hot environments |

Introduction to Enamelware and Lacquerware

Enamelware consists of metal objects coated with a smooth, durable layer of powdered glass fused through high heat, providing resistance to corrosion and attractive glossy finishes. Lacquerware involves applying multiple layers of lacquer derived from tree sap onto wooden or metal surfaces, resulting in a hard, glossy coating that enhances durability and aesthetic appeal. Both crafts offer unique cultural significance and practical uses, with enamelware favored for kitchenware durability and lacquerware prized for artistic decorative pieces.

Historical Background of Enamelware

Enamelware, originating in the early 19th century Europe, gained popularity for its durable and heat-resistant qualities, revolutionizing cookware and household items. Its production involves fusing powdered glass to metal at high temperatures, creating a glossy, protective coating that resists rust and corrosion. This technique contrasts with lacquerware, which uses natural resin coatings predominantly in East Asia, emphasizing artistic craftsmanship over industrial durability.

Origins and Evolution of Lacquerware

Lacquerware originated over 7,000 years ago in ancient China and has evolved through intricate techniques involving layers of resin derived from the lacquer tree (Toxicodendron vernicifluum). Unlike enamelware, which uses powdered glass fused to metal surfaces, lacquerware's evolution highlights cultural significance across East Asia, reflecting artistic craftsmanship in Japan, Korea, and Vietnam. The enduring use of natural lacquer and hand-crafted decoration distinguishes lacquerware's traditional heritage and preservation of artisanal methods.

Material Composition: Enamelware vs Lacquerware

Enamelware consists of a metal base, typically steel or cast iron, coated with a vitreous enamel layer made from powdered glass fused at high temperatures, providing a durable, non-porous surface resistant to heat and corrosion. Lacquerware is crafted from wood, bamboo, or metal substrates coated with multiple layers of natural or synthetic lacquer derived from tree sap, forming a glossy, protective finish that is lightweight yet prone to chipping. The fundamental difference lies in enamelware's inorganic glass coating versus lacquerware's organic resin-based surface, impacting durability, heat resistance, and care requirements.

Manufacturing Processes Compared

Enamelware manufacturing involves coating metal, typically steel or cast iron, with a layer of powdered glass fused through high-temperature firing, which creates a durable, heat-resistant surface. Lacquerware production requires applying multiple thin layers of lacquer derived from the sap of lacquer trees onto wood or metal substrates, with each layer carefully dried and polished to achieve a glossy, protective finish. The enamelware process emphasizes high heat and chemical bonding, while lacquerware relies on meticulous hand-layering and curing for its characteristic appearance and resilience.

Durability and Maintenance Differences

Enamelware, made from metal coated with a layer of enamel, offers high durability due to its resistance to scratches, heat, and corrosion, making it ideal for everyday use and outdoor cooking. Lacquerware, crafted from wood or metal coated with lacquer, is more delicate and prone to chipping or cracking, requiring careful handling and avoidance of abrasive cleaning methods. Maintenance for enamelware is straightforward with simple hand washing or dishwasher compatibility, whereas lacquerware demands gentle cleaning with mild soap and soft cloths to preserve its glossy finish and prevent damage.

Aesthetic Appeal and Design Varieties

Enamelware boasts a glossy, vibrant finish with a broad spectrum of colors and retro-inspired patterns that enhance kitchen aesthetics and vintage decor themes. Lacquerware offers a sophisticated, polished surface often featuring intricate hand-painted designs and rich, deep hues like reds, blacks, and golds emblematic of East Asian craftsmanship. Both materials provide unique aesthetic appeal, with enamelware favoring bold, modern or nostalgic looks while lacquerware excels in elegant, artistic expressions and cultural motifs.

Practical Uses in Modern Homes

Enamelware offers durability and heat resistance, making it ideal for cookware, bakeware, and outdoor dining in modern homes. Lacquerware's lightweight, glossy finish suits decorative items, serving trays, and storage containers, adding aesthetic appeal without compromising function. Both materials complement contemporary kitchens by balancing practical use with stylish presentation.

Environmental Impact and Sustainability

Enamelware is made by fusing powdered glass to metal at high temperatures, resulting in a durable, non-toxic, and recyclable product that reduces environmental waste. Lacquerware, created from natural resins applied to wood or bamboo, is biodegradable and often handcrafted, supporting sustainable forestry practices and minimal chemical use. Both materials offer eco-friendly options, but enamelware's recyclability and longevity provide a lower environmental footprint in mass production contexts.

Choosing Between Enamelware and Lacquerware

Choosing between enamelware and lacquerware depends on durability and aesthetic preferences. Enamelware offers a robust, heat-resistant surface ideal for everyday kitchen use, while lacquerware provides a glossy, decorative finish suited for serving and display purposes. Consider enamelware for practical, long-lasting cookware and lacquerware for elegant, traditional table settings.

Enamelware Infographic

libterm.com

libterm.com