Hardboard is a dense, engineered wood product made from compressed wood fibers, offering superior strength and durability compared to traditional plywood or particleboard. It is commonly used in furniture, cabinetry, and wall paneling due to its smooth surface and resistance to warping or cracking. Discover how hardboard can enhance your next project by exploring the full details in this article.

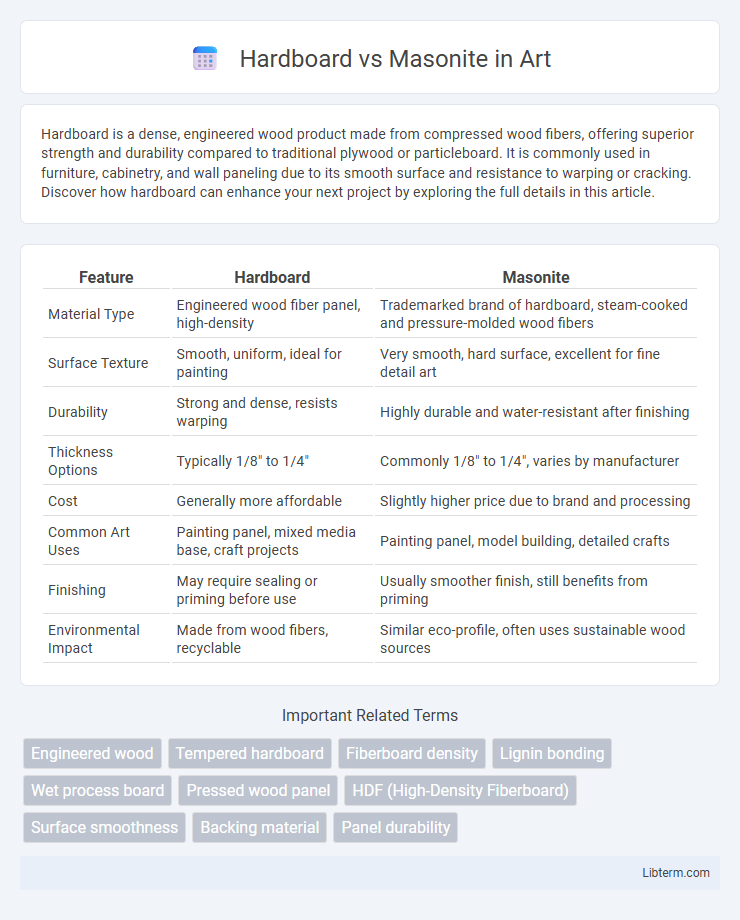

Table of Comparison

| Feature | Hardboard | Masonite |

|---|---|---|

| Material Type | Engineered wood fiber panel, high-density | Trademarked brand of hardboard, steam-cooked and pressure-molded wood fibers |

| Surface Texture | Smooth, uniform, ideal for painting | Very smooth, hard surface, excellent for fine detail art |

| Durability | Strong and dense, resists warping | Highly durable and water-resistant after finishing |

| Thickness Options | Typically 1/8" to 1/4" | Commonly 1/8" to 1/4", varies by manufacturer |

| Cost | Generally more affordable | Slightly higher price due to brand and processing |

| Common Art Uses | Painting panel, mixed media base, craft projects | Painting panel, model building, detailed crafts |

| Finishing | May require sealing or priming before use | Usually smoother finish, still benefits from priming |

| Environmental Impact | Made from wood fibers, recyclable | Similar eco-profile, often uses sustainable wood sources |

Introduction to Hardboard and Masonite

Hardboard, a dense engineered wood product made from wood fibers compressed under high heat and pressure, offers excellent durability and smooth surface finish ideal for furniture and cabinetry. Masonite, a specific brand of hardboard developed in the 1920s, is known for its consistent density and water-resistant properties, making it popular for doors, paneling, and construction applications. Both materials provide versatile, cost-effective solutions with differences primarily in manufacturing processes and performance characteristics.

Defining Hardboard: Key Features

Hardboard, also known as high-density fiberboard (HDF), is a wood-based panel product made by compressing wood fibers under high pressure and heat, resulting in a dense, smooth surface with high strength and durability. Its key features include resistance to warping, excellent nail-holding ability, and a smooth finish that is ideal for painting or laminating. Hardboard is typically thicker and denser than Masonite, making it suitable for structural applications, furniture backing, and cabinetry where rigidity and impact resistance are essential.

What Is Masonite? Overview and Characteristics

Masonite is a type of hardboard made from wood fibers that are steam-cooked and then pressure-molded into dense, smooth panels. Known for its durability, smooth surface, and versatility, Masonite is commonly used in furniture, doors, and cabinetry applications. Its dense composition provides excellent resistance to impact and warping, making it a popular choice in construction and woodworking projects.

Manufacturing Processes: Hardboard vs Masonite

Hardboard is manufactured by compressing wood fibers under high heat and pressure without adhesives, resulting in a dense, smooth panel with superior strength and durability. Masonite is produced through the Mason method, where steamed wood chips are pressure-cooked to break down fibers, then formed into a hardboard sheet with a smooth finish; the process also relies on natural lignin as a binder. Both manufacturing processes influence the board's density, moisture resistance, and surface texture, determining their suitability for various construction and furniture applications.

Strength and Durability Comparison

Hardboard offers superior strength and durability due to its dense fiber composition and high-pressure manufacturing process, making it resistant to impact and wear. Masonite, while also durable, tends to be less dense and more prone to swelling or warping when exposed to moisture compared to hardboard. The enhanced structural integrity of hardboard makes it a preferred choice for heavy-duty applications requiring long-lasting performance.

Surface Texture and Finish Differences

Hardboard features a smooth, dense surface with a fine texture ideal for painting and laminating, while Masonite offers a slightly rougher finish due to its tempered hardboard manufacturing process. The surface of Masonite is often more porous and fibrous, making it better suited for applications requiring adhesion of finishes or coatings. Hardboard's uniform surface texture ensures a sleek, consistent finish, contrasting with Masonite's natural grain patterns and robust feel.

Common Applications of Hardboard and Masonite

Hardboard is commonly used in furniture backing, cabinetry, and underlayment due to its high density and smooth surface, offering durability and a stable base. Masonite, often employed in doors, wall paneling, and craft projects, provides a versatile, smooth finish ideal for painting and decorative applications. Both materials find extensive use in construction and woodworking but are chosen based on specific requirements like strength and aesthetic finish.

Environmental Impact and Sustainability

Hardboard and Masonite both originate from wood fibers, but Hardboard typically uses denser, more compressed fibers, resulting in a more energy-intensive production process. Masonite production employs a steam pressure process that uses fewer chemicals and allows for more efficient recycling of wood materials, enhancing its sustainability profile. Lifecycle analyses indicate Masonite often has a lower carbon footprint and greater potential for biodegradability compared to conventional Hardboard.

Cost Analysis: Hardboard vs Masonite

Hardboard typically costs less than Masonite, making it a budget-friendly option for projects requiring a smooth, dense panel. Masonite, known for its durability and resistance to moisture, carries a higher price due to its manufacturing process that involves steam-cooked wood fibers. When comparing Hardboard vs Masonite in terms of cost analysis, Hardboard offers savings upfront, but Masonite's enhanced performance may justify the investment for applications needing long-term durability.

Choosing the Best Material: Which Is Right for Your Project?

Hardboard offers a dense, smooth surface ideal for furniture, cabinetry, and wall paneling, providing durability and moisture resistance suitable for interior applications. Masonite, a type of hardboard formed by steam-cooking and pressure-molding wood fibers, features a smoother finish and higher density, making it better for precise crafts, doors, and decorative paneling. Selecting the right material depends on project requirements like strength, finish, moisture exposure, and budget, with hardboard favored for structural uses and Masonite preferred for aesthetic and fine-detail work.

Hardboard Infographic

libterm.com

libterm.com