Screenprint offers a cost-effective and durable method for producing vibrant, high-quality images on various materials. The process involves creating a stencil and using it to apply layers of ink, ensuring excellent color saturation and longevity. Discover how screenprinting can elevate Your designs and explore the full potential of this versatile technique in the rest of the article.

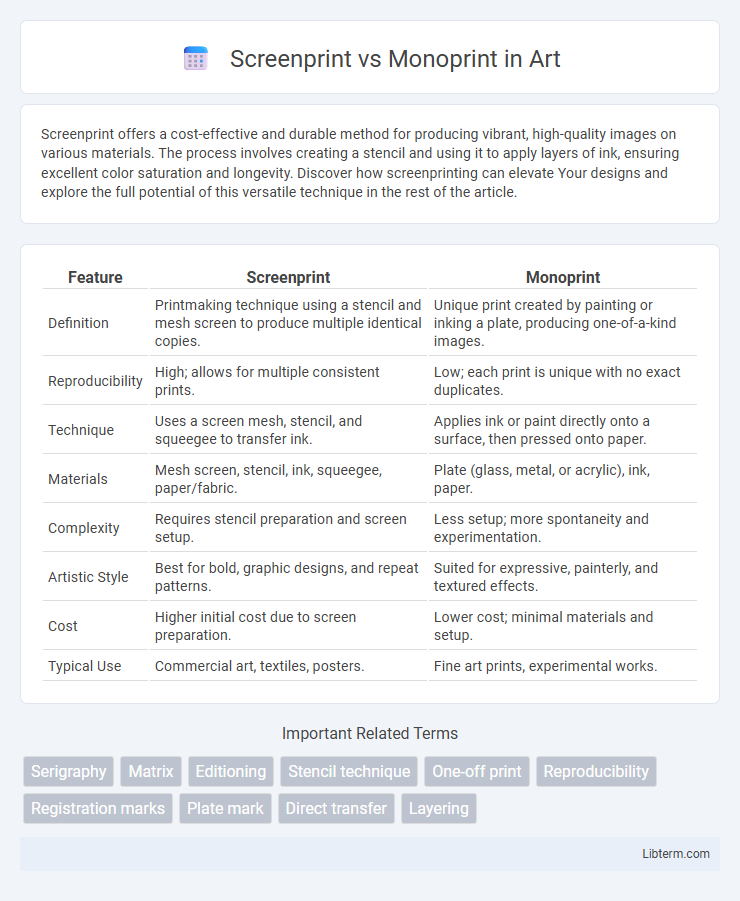

Table of Comparison

| Feature | Screenprint | Monoprint |

|---|---|---|

| Definition | Printmaking technique using a stencil and mesh screen to produce multiple identical copies. | Unique print created by painting or inking a plate, producing one-of-a-kind images. |

| Reproducibility | High; allows for multiple consistent prints. | Low; each print is unique with no exact duplicates. |

| Technique | Uses a screen mesh, stencil, and squeegee to transfer ink. | Applies ink or paint directly onto a surface, then pressed onto paper. |

| Materials | Mesh screen, stencil, ink, squeegee, paper/fabric. | Plate (glass, metal, or acrylic), ink, paper. |

| Complexity | Requires stencil preparation and screen setup. | Less setup; more spontaneity and experimentation. |

| Artistic Style | Best for bold, graphic designs, and repeat patterns. | Suited for expressive, painterly, and textured effects. |

| Cost | Higher initial cost due to screen preparation. | Lower cost; minimal materials and setup. |

| Typical Use | Commercial art, textiles, posters. | Fine art prints, experimental works. |

Understanding Screenprinting: Definition and Process

Screenprinting is a versatile printmaking technique where ink is pushed through a fine mesh stencil onto a substrate, creating sharp and vibrant images. The process involves preparing a screen with a blocked-off design area, applying ink, and using a squeegee to force the ink through the mesh openings onto materials such as fabric, paper, or plastic. This method allows for precise layering of colors and is widely used for producing consistent, high-quality prints in commercial and artistic applications.

What is Monoprinting? Technique and Characteristics

Monoprinting is a unique printmaking technique that produces a single, original impression by applying ink or paint onto a smooth surface such as glass or metal and then transferring it to paper or fabric. The process allows for spontaneous creativity and variations in texture and color, making each print one-of-a-kind unlike screenprinting, which uses a stencil and mesh screen to create multiple consistent copies. Characteristics of monoprints include visible brushstrokes, irregular patterns, and a painterly quality that emphasizes the artist's hand and improvisation.

Key Differences Between Screenprint and Monoprint

Screenprint involves transferring ink through a stencil on a mesh screen, producing multiple identical copies with consistent designs and vibrant colors. Monoprint, by contrast, creates unique, one-of-a-kind prints by applying ink directly onto a smooth surface and pressing paper onto it, resulting in varied textures and unpredictable effects. Screenprint excels in durability and repeatability, while monoprint is valued for its spontaneity and artistic originality.

Materials Required for Screenprinting vs Monoprinting

Screenprinting requires materials such as a mesh screen, squeegee, stencil, and specialized inks designed for fabric or paper surfaces. Monoprinting involves a printing plate or matrix, like a glass or metal sheet, along with inks, a brayer for ink application, and paper to transfer the image, emphasizing unique one-off prints. The distinct materials highlight the repeatability of screenprinting versus the singular creativity of monoprinting processes.

Artistic Outcomes: Repeatability and Uniqueness

Screenprinting offers high repeatability, enabling artists to produce multiple identical copies with consistent color and detail, ideal for limited editions and commercial art. Monoprinting emphasizes uniqueness, as each print results from one-time, spontaneous application of ink, creating rich textures and unpredictable effects that cannot be exactly replicated. Artists often choose screenprinting for precision and uniformity, while monoprinting appeals to those seeking expressive, singular artistic outcomes.

Popular Applications of Screenprint and Monoprint

Screenprint is widely used in commercial applications such as textile printing, poster production, and packaging due to its ability to produce vibrant colors and sharp details at high volume. Monoprint, favored by fine artists, is commonly applied in unique art pieces, experimental prints, and customized greeting cards, emphasizing one-of-a-kind textures and spontaneous imagery. Both techniques offer distinct creative potentials: screenprint excels in mass replication, whereas monoprint serves artistic individuality and limited editions.

Pros and Cons of Screenprinting

Screenprinting offers high durability and vibrant color reproduction, making it ideal for mass production of posters, textiles, and signage. Its main drawbacks include longer setup times and higher initial costs compared to monoprint, which is better suited for unique, one-off artworks. The precision of screenprinting allows for consistent replication, but it lacks the spontaneity and texture variation found in monoprint techniques.

Pros and Cons of Monoprinting

Monoprinting offers unique artistic expression through one-of-a-kind prints that cannot be exactly duplicated, fostering creativity and experimentation. Its flexibility allows the artist to combine different textures and materials, but the process can be time-consuming and less predictable compared to screenprinting. However, the inability to produce consistent multiple copies makes monoprinting less practical for commercial or large-scale projects.

Choosing the Right Printing Method for Your Project

Screenprint offers vibrant colors and durability, making it ideal for bulk printing on textiles and posters where consistency is key. Monoprint provides unique, one-of-a-kind prints perfect for artistic projects requiring individuality and texture variations. Selecting the right method depends on the project's goals, volume needs, and desired aesthetic effects.

Cost Comparison: Screenprinting vs Monoprinting

Screenprinting generally involves higher upfront costs due to the need for screens, specialized inks, and setup time, making it more cost-effective for large production runs. Monoprinting requires fewer materials and minimal setup, resulting in lower initial expenses but higher per-print costs due to its one-off nature. For budget-conscious projects with limited quantities, monoprinting offers a more affordable option, whereas screenprinting is preferable for economies of scale.

Screenprint Infographic

libterm.com

libterm.com