Ceramic shell casting offers precise metal casting with complex geometries and superior surface finishes, making it ideal for aerospace, automotive, and art applications. This process combines ceramic materials to create a durable mold that withstands high temperatures and produces detailed, defect-free components. Discover how ceramic shell casting can enhance your manufacturing projects by reading the full article.

Table of Comparison

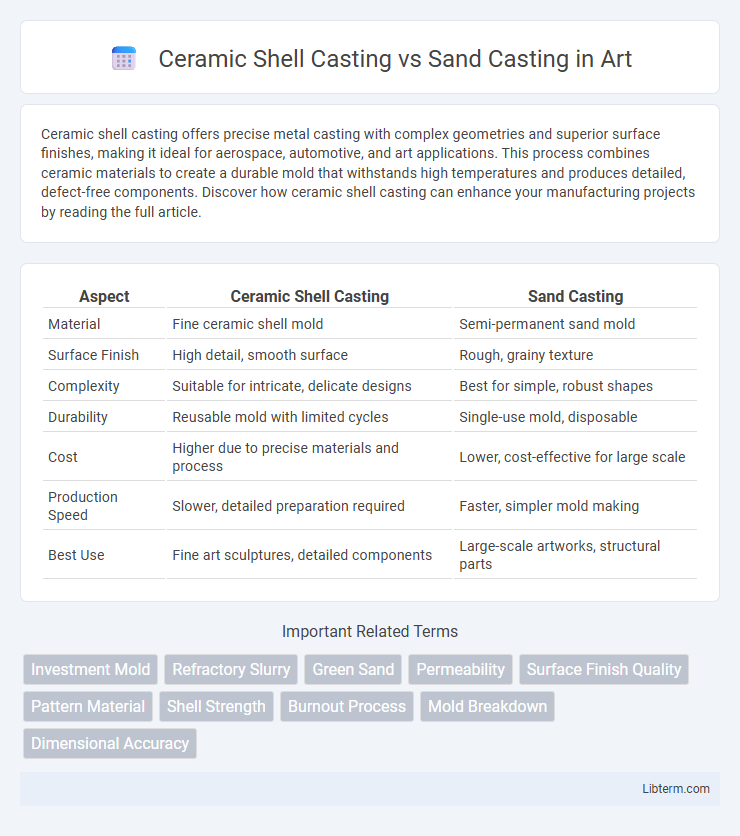

| Aspect | Ceramic Shell Casting | Sand Casting |

|---|---|---|

| Material | Fine ceramic shell mold | Semi-permanent sand mold |

| Surface Finish | High detail, smooth surface | Rough, grainy texture |

| Complexity | Suitable for intricate, delicate designs | Best for simple, robust shapes |

| Durability | Reusable mold with limited cycles | Single-use mold, disposable |

| Cost | Higher due to precise materials and process | Lower, cost-effective for large scale |

| Production Speed | Slower, detailed preparation required | Faster, simpler mold making |

| Best Use | Fine art sculptures, detailed components | Large-scale artworks, structural parts |

Introduction to Metal Casting Methods

Metal casting methods like ceramic shell casting and sand casting are essential for producing complex metal parts with high precision and durable properties. Ceramic shell casting uses thin ceramic layers to create detailed molds, offering superior surface finish and dimensional accuracy compared to sand casting, which employs compacted sand molds for versatility and cost-effectiveness. Understanding these differences enables manufacturers to select the ideal process based on factors such as production volume, part complexity, and material type.

Overview of Ceramic Shell Casting

Ceramic shell casting involves creating a thin, ceramic-based mold around a wax pattern, offering superior surface finish and dimensional accuracy compared to sand casting. This process is commonly used for complex and high-precision metal parts in aerospace and automotive industries, where intricate details and tight tolerances are critical. The ceramic shell mold also withstands higher temperatures, enabling the casting of high-melting-point alloys not feasible with traditional sand molds.

Overview of Sand Casting

Sand casting is a versatile and cost-effective metal casting process that uses a sand-based mold to create intricate and large components with excellent dimensional accuracy. This method supports a wide range of metals and alloys, making it popular in industries such as automotive, aerospace, and machinery manufacturing. Its relatively low tooling cost and ability to handle complex geometries make sand casting ideal for both prototype and mass production runs.

Material Compatibility: Metals and Alloys

Ceramic shell casting excels in compatibility with high-melting-point metals and superalloys such as titanium, Inconel, and stainless steel, due to its superior refractory properties. Sand casting is better suited for ferrous and non-ferrous metals like cast iron, steel, aluminum, and brass, providing flexibility but with coarser surface finishes. The choice between these methods depends on the alloy's melting temperature and required casting precision.

Surface Finish and Dimensional Accuracy

Ceramic shell casting provides superior surface finish with fine detail replication and minimal roughness compared to sand casting, which typically results in a coarser texture due to the granular nature of sand molds. The dimensional accuracy of ceramic shell casting is higher, achieving tighter tolerances and minimal shrinkage, making it ideal for complex geometries and precision components. Sand casting, while more cost-effective for large, simple parts, usually exhibits greater dimensional variation and surface irregularities.

Complexity and Design Capabilities

Ceramic shell casting offers superior complexity and design capabilities compared to sand casting, enabling the production of intricate shapes with fine details and thin walls unattainable by traditional sand molds. The ceramic shell's high strength and heat resistance allow for precise replication of complex geometries and tight tolerances, making it ideal for aerospace and turbine components. In contrast, sand casting is limited by coarser mold textures and lower dimensional accuracy, restricting its ability to produce highly detailed or delicate parts.

Production Speed and Efficiency

Ceramic shell casting offers higher production speed and efficiency due to its ability to produce intricate and thin-walled components with less tooling time compared to sand casting. Sand casting requires longer mold preparation and cooling periods, which slows down overall production cycles. The precision of ceramic shell molds reduces finishing work, enhancing efficiency in high-volume manufacturing settings.

Cost Comparison: Ceramic Shell vs Sand Casting

Ceramic shell casting generally incurs higher initial costs due to the elaborate mold-making process and the use of advanced materials, making it suitable for complex, high-precision components. Sand casting offers lower upfront expenses and greater flexibility for larger, less intricate parts, ideal for short production runs. Over time, ceramic shell casting can reduce overall expenses by minimizing machining and finishing requirements, whereas sand casting may increase post-casting labor costs.

Environmental Impact and Waste Management

Ceramic shell casting generates less waste compared to sand casting due to its reusable ceramic molds and precise material usage, minimizing environmental pollution. Sand casting produces significant amounts of spent sand, often requiring specialized disposal or recycling processes to manage silica dust and binders, which can impact soil and water quality negatively. The high energy consumption in sand casting during mold preparation and cleanup contrasts with the more energy-efficient ceramic shell process, making the latter a greener choice for metal casting industries focused on sustainability.

Choosing the Right Casting Process for Your Project

Ceramic shell casting offers superior surface finish and dimensional accuracy, making it ideal for complex geometries and high-temperature alloys, whereas sand casting excels in cost-efficiency and versatility for larger, simpler parts. Selecting the right casting process depends on factors such as production volume, material type, design complexity, and budget constraints. Evaluating these parameters ensures optimal performance, quality, and cost-effectiveness tailored to specific project requirements.

Ceramic Shell Casting Infographic

libterm.com

libterm.com