Lost wax casting is an ancient metalworking technique used to create intricate, detailed sculptures and jewelry by pouring molten metal into a mold made from a wax model. This process allows for high precision and fine surface textures that are difficult to achieve with other methods. Discover how lost wax casting can transform your creative ideas into stunning metal masterpieces by reading the full article.

Table of Comparison

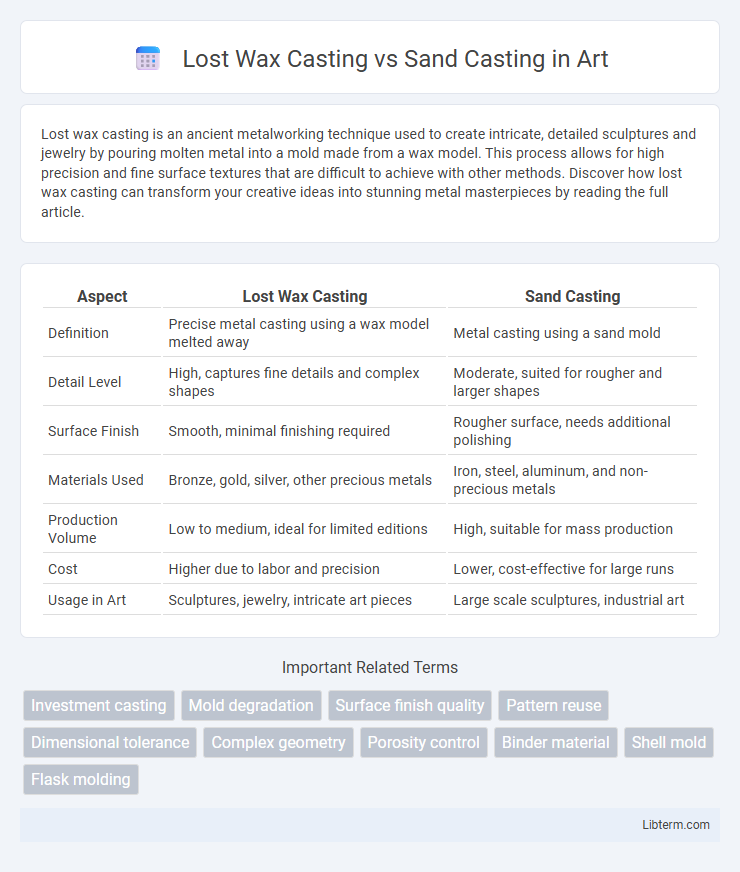

| Aspect | Lost Wax Casting | Sand Casting |

|---|---|---|

| Definition | Precise metal casting using a wax model melted away | Metal casting using a sand mold |

| Detail Level | High, captures fine details and complex shapes | Moderate, suited for rougher and larger shapes |

| Surface Finish | Smooth, minimal finishing required | Rougher surface, needs additional polishing |

| Materials Used | Bronze, gold, silver, other precious metals | Iron, steel, aluminum, and non-precious metals |

| Production Volume | Low to medium, ideal for limited editions | High, suitable for mass production |

| Cost | Higher due to labor and precision | Lower, cost-effective for large runs |

| Usage in Art | Sculptures, jewelry, intricate art pieces | Large scale sculptures, industrial art |

Introduction to Metal Casting Processes

Metal casting processes such as lost wax casting and sand casting serve distinct purposes in manufacturing, each offering unique advantages based on complexity and precision requirements. Lost wax casting excels in producing intricate and finely detailed components by using a wax model coated with ceramic material, whereas sand casting utilizes reusable sand molds ideal for larger, less detailed parts. Both techniques involve melting metal and pouring it into molds, but lost wax casting is preferred for high-precision applications, while sand casting is cost-effective for mass production of bulky items.

Overview of Lost Wax Casting

Lost wax casting, also known as investment casting, is a precise metal casting process where a wax model is coated with refractory ceramic material to create a mold, which is then melted away to leave a cavity for molten metal. This technique enables the production of complex shapes with fine detail and smooth surface finishes, making it ideal for jewelry, aerospace components, and intricate sculptures. The ability to replicate intricate designs with high dimensional accuracy distinguishes lost wax casting from sand casting.

Overview of Sand Casting

Sand casting, a versatile and cost-effective metal casting method, involves creating a mold from compacted sand to shape molten metal into desired forms. This process is ideal for producing large, complex components with intricate designs and varying sizes, commonly used in industries such as automotive, aerospace, and machinery manufacturing. Sand casting offers advantages like quick mold preparation and the ability to reuse sand, making it suitable for both small-scale and mass production runs.

Material Compatibility and Applications

Lost wax casting offers superior compatibility with intricate metals such as gold, silver, and bronze, making it ideal for precise jewelry and detailed art sculptures. Sand casting accommodates a wider range of metals including iron, aluminum, and steel, suited for large industrial components like engine blocks and machinery parts. The choice depends on desired detail level and metal type, with lost wax excelling in fine, complex designs and sand casting favoring robust, large-scale production.

Surface Finish and Detail Precision

Lost wax casting delivers superior surface finish and intricate detail precision due to its ability to replicate fine patterns from wax molds, making it ideal for artistic and highly detailed metal parts. Sand casting offers a rougher surface texture and less precise detail reproduction because the granular sand mold limits the resolution of intricate features, often requiring secondary machining. For applications demanding smooth surfaces and exact details, lost wax casting is preferable, while sand casting suits larger, less detailed components with a cost-effective approach.

Production Speed and Efficiency

Lost wax casting offers faster production cycles for intricate and precise components due to its ability to produce detailed molds directly from wax patterns, reducing finishing time. In contrast, sand casting involves longer mold preparation and cooling times, making it less efficient for high-volume or complex designs. For rapid prototyping and high-precision parts, lost wax casting demonstrates superior production speed and overall efficiency compared to sand casting.

Cost Considerations

Lost wax casting typically involves higher upfront costs due to wax model creation and intricate mold preparation, making it more expensive for small production runs. Sand casting offers lower initial costs with reusable sand molds and simpler processes, providing cost efficiency for large-scale or bulky metal parts. Choosing between these methods depends on balancing the complexity of the design, production volume, and budget constraints.

Design Flexibility and Complexity

Lost wax casting offers superior design flexibility and can produce highly complex and intricate shapes with fine detail, making it ideal for intricate jewelry, aerospace components, and artistic sculptures. Sand casting, while more cost-effective for larger and simpler parts, has limitations in achieving fine details and complex geometries due to the granular nature of the sand mold. The precision of lost wax casting enables thinner walls and smoother surface finishes compared to the rougher texture and reduced design complexity inherent to sand casting.

Environmental Impact and Waste

Lost wax casting generates less solid waste due to the use of reusable molds made from wax, which can be melted and recycled, minimizing environmental impact. In contrast, sand casting produces considerable waste from disposable sand molds that require disposal or restoration, leading to higher landfill contributions. Furthermore, lost wax casting often consumes less energy and releases fewer emissions during the melting and casting process compared to sand casting.

Choosing the Right Casting Method

Lost wax casting offers high precision and intricate detail, making it ideal for complex designs and small production runs. Sand casting is more cost-effective for larger parts and high-volume manufacturing but provides less detail accuracy. Selecting the right method depends on factors like design complexity, production quantity, material type, and budget constraints.

Lost Wax Casting Infographic

libterm.com

libterm.com