Industrial wastewater contains contaminants that can harm ecosystems and human health if not properly treated. Effective management and treatment processes are essential to remove pollutants and comply with environmental regulations. Discover how advanced strategies can help protect your environment by reading the rest of this article.

Table of Comparison

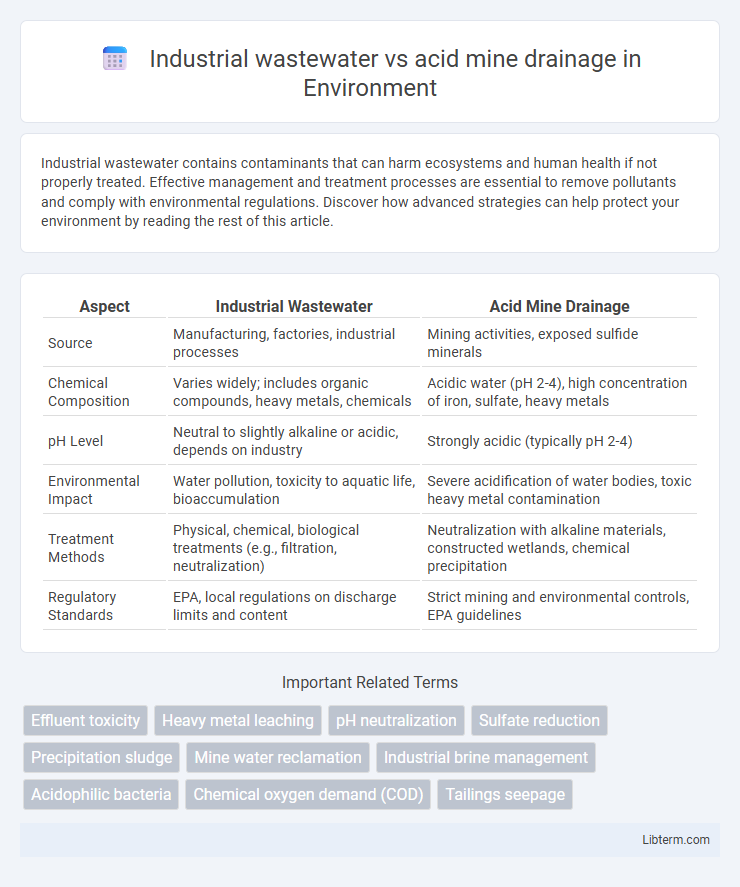

| Aspect | Industrial Wastewater | Acid Mine Drainage |

|---|---|---|

| Source | Manufacturing, factories, industrial processes | Mining activities, exposed sulfide minerals |

| Chemical Composition | Varies widely; includes organic compounds, heavy metals, chemicals | Acidic water (pH 2-4), high concentration of iron, sulfate, heavy metals |

| pH Level | Neutral to slightly alkaline or acidic, depends on industry | Strongly acidic (typically pH 2-4) |

| Environmental Impact | Water pollution, toxicity to aquatic life, bioaccumulation | Severe acidification of water bodies, toxic heavy metal contamination |

| Treatment Methods | Physical, chemical, biological treatments (e.g., filtration, neutralization) | Neutralization with alkaline materials, constructed wetlands, chemical precipitation |

| Regulatory Standards | EPA, local regulations on discharge limits and content | Strict mining and environmental controls, EPA guidelines |

Introduction to Industrial Wastewater and Acid Mine Drainage

Industrial wastewater consists of liquid waste generated from manufacturing processes, containing contaminants such as heavy metals, organic compounds, and suspended solids that require specialized treatment before discharge. Acid mine drainage results from the oxidation of sulfide minerals in mining operations, producing highly acidic water rich in iron, aluminum, and toxic metals that severely impact aquatic ecosystems. Both wastewaters pose significant environmental challenges, necessitating distinct remediation approaches tailored to their unique chemical compositions and sources.

Key Sources and Origins of Contaminants

Industrial wastewater primarily originates from manufacturing processes, chemical production, and metal finishing, releasing contaminants such as heavy metals, organic compounds, and toxic chemicals. Acid mine drainage stems from the exposure of sulfide minerals to air and water during mining activities, producing sulfuric acid and mobilizing heavy metals like iron, lead, and arsenic. Both sources contribute significantly to water pollution but differ in their contaminant profiles and environmental impacts due to distinct origins and chemical reactions.

Chemical Composition Differences

Industrial wastewater typically contains a complex mixture of organic compounds, heavy metals, and nutrients such as nitrogen and phosphorus, varying widely based on the specific industry. Acid mine drainage is characterized by high acidity (low pH) and elevated concentrations of dissolved metals like iron, aluminum, and manganese, along with sulfate ions resulting from the oxidation of sulfide minerals. The primary chemical difference lies in acid mine drainage's strong acidity and sulfate dominance compared to the more heterogeneous chemical profile and variable pH of industrial wastewater.

Environmental Impacts

Industrial wastewater often contains heavy metals, toxic chemicals, and organic pollutants that can severely disrupt aquatic ecosystems and contaminate groundwater sources. Acid mine drainage, characterized by acidic water rich in dissolved iron and sulfates, leads to significant soil degradation and acidification of nearby water bodies, causing widespread harm to aquatic life and biodiversity. Both pollution types contribute to long-term environmental damage, threatening water quality and ecosystem health in mining and industrial regions.

Regulatory Frameworks and Standards

Industrial wastewater and acid mine drainage (AMD) are subject to distinct regulatory frameworks due to their differing chemical compositions and environmental impacts. Industrial wastewater regulations, such as the Clean Water Act (CWA) in the United States, establish effluent limits based on pollutant types specific to manufacturing processes, while AMD is regulated under mining-specific statutes like the Surface Mining Control and Reclamation Act (SMCRA) and subject to stringent pH and heavy metals standards. Compliance monitoring for AMD often requires additional parameters, including metals such as iron, aluminum, and sulfates, reflecting its acidic nature and toxic runoff potential compared to more diverse industrial effluents.

Treatment Technologies Comparison

Industrial wastewater treatment primarily utilizes physical, chemical, and biological processes such as sedimentation, coagulation-flocculation, activated sludge, and membrane filtration to remove contaminants including heavy metals, organic compounds, and suspended solids. Acid mine drainage treatment often involves neutralization of acidic pH using lime or alkaline materials, followed by metal precipitation and constructed wetlands for residual metal and sulfate removal. Advanced technologies like chemical precipitation and bioremediation are common to both, but acid mine drainage treatment requires specialized acid neutralization and long-term passive treatment systems due to its persistent acidity and metal toxicity.

Challenges in Monitoring and Management

Industrial wastewater and acid mine drainage (AMD) present distinct challenges in monitoring and management due to their complex chemical compositions and fluctuating pollutant loads. Industrial wastewater often contains a variety of synthetic chemicals and heavy metals that require advanced real-time sensing technologies for accurate detection and treatment optimization. AMD is characterized by low pH and high concentrations of iron, sulfur, and toxic metals, demanding continuous monitoring with specialized equipment to prevent environmental damage and ensure compliance with strict regulatory standards.

Case Studies: Industrial vs Mining Sites

Case studies comparing industrial wastewater and acid mine drainage reveal distinct contamination profiles and remediation challenges, with industrial sites often generating heavy metals, organic compounds, and high biochemical oxygen demand, while acid mine drainage predominantly releases sulfuric acid and dissolved metals like iron, copper, and arsenic. Research at mining sites such as the Iron Mountain Mine illustrates persistent acidic effluents contaminating nearby water bodies, contrasted by industrial zones like textile manufacturing plants, where treatment processes target dye pollutants and chemical oxygen demand. Effective management strategies require site-specific approaches informed by case-specific hydrochemical data and pollutant source characterization.

Innovations in Wastewater Remediation

Innovations in wastewater remediation have increasingly targeted the distinct challenges posed by industrial wastewater and acid mine drainage, employing advanced treatment technologies such as membrane filtration, bioremediation, and electrocoagulation. Cutting-edge biotechnological approaches utilize acidophilic microbes to neutralize acidity and precipitate heavy metals specifically in acid mine drainage, while industrial wastewater treatment benefits from integrated systems combining chemical oxidation and constructed wetlands for efficient pollutant removal. Recent developments in nanomaterials and sensor technologies enable real-time monitoring and enhanced contaminant degradation, optimizing remediation processes tailored to the complex compositions of both wastewater types.

Future Trends in Pollution Control

Future trends in pollution control emphasize advanced treatment technologies like membrane filtration and bioelectrochemical systems for both industrial wastewater and acid mine drainage, aiming to enhance contaminant removal efficiency and resource recovery. Innovations in real-time monitoring combined with AI-driven data analytics are becoming crucial for early detection and adaptive management of pollutants in complex wastewater streams. Integration of sustainable practices such as circular economy principles and zero liquid discharge systems is projected to reduce environmental impact and promote water reuse across industries and mining operations.

Industrial wastewater Infographic

libterm.com

libterm.com