Bioreactors provide controlled environments essential for optimizing biological reactions, supporting applications from pharmaceuticals to biofuels production. They enhance cellular growth and metabolic activity by regulating parameters such as temperature, pH, and oxygen levels. Explore this article to discover how bioreactors can transform your bioprocessing strategies and improve efficiency.

Table of Comparison

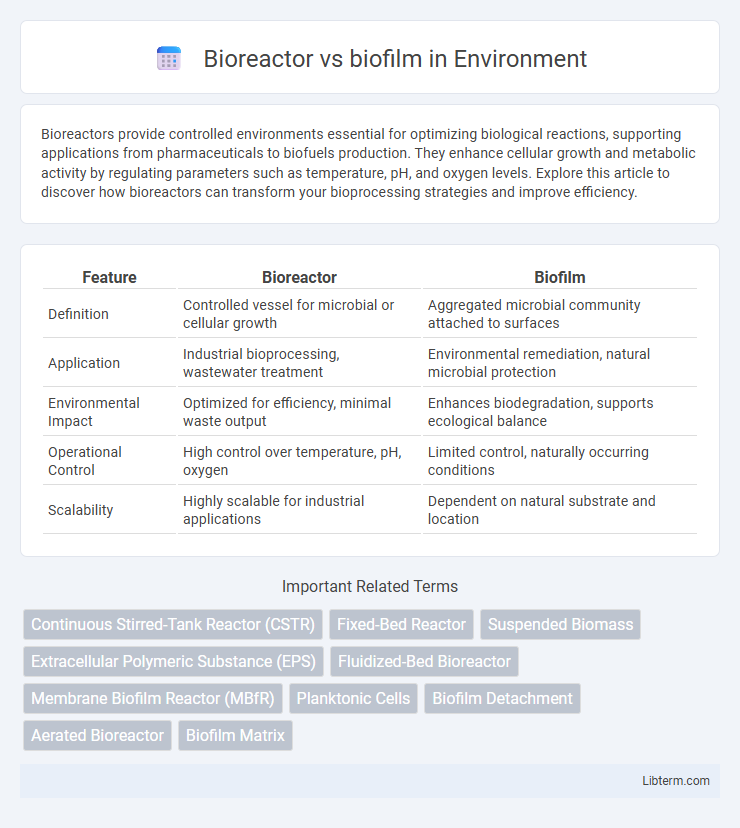

| Feature | Bioreactor | Biofilm |

|---|---|---|

| Definition | Controlled vessel for microbial or cellular growth | Aggregated microbial community attached to surfaces |

| Application | Industrial bioprocessing, wastewater treatment | Environmental remediation, natural microbial protection |

| Environmental Impact | Optimized for efficiency, minimal waste output | Enhances biodegradation, supports ecological balance |

| Operational Control | High control over temperature, pH, oxygen | Limited control, naturally occurring conditions |

| Scalability | Highly scalable for industrial applications | Dependent on natural substrate and location |

Introduction to Bioreactors and Biofilms

Bioreactors are engineered systems designed to support biologically active environments for the cultivation of cells or microorganisms under controlled conditions, optimizing factors such as temperature, pH, and oxygen levels to enhance productivity. Biofilms consist of complex microbial communities that adhere to surfaces and are embedded in a self-produced extracellular matrix, allowing microorganisms to survive in diverse environments and resist antimicrobial agents. Understanding the fundamental differences between bioreactors and biofilms is crucial for applications in wastewater treatment, bioprocessing, and medical device management.

Key Definitions: Bioreactor vs Biofilm

A bioreactor is a controlled system designed to optimize biological reactions, typically for industrial or research purposes such as fermentation or wastewater treatment. Biofilm refers to a complex aggregation of microorganisms adhered to a surface, embedded within a self-produced extracellular matrix, often seen in natural and clinical environments. The primary distinction lies in bioreactors being engineered environments for microbial growth, while biofilms represent naturally occurring microbial communities on surfaces.

Structural Differences

Bioreactors are engineered systems designed for controlled microbial growth, featuring reactors such as stirred-tank or packed-bed types with suspended or immobilized cells, allowing precise environmental regulation. Biofilms consist of microbial communities attached to surfaces within an extracellular polymeric substance (EPS) matrix, creating a highly structured, heterogeneous environment with nutrient gradients and spatial organization. Structural differences lie in containment and organization: bioreactors facilitate homogeneous mixing and suspension, while biofilms form complex, surface-bound, multi-layered aggregates with distinct microenvironments.

Mechanisms of Action

Bioreactors facilitate microbial growth by controlling environmental factors such as nutrient supply, temperature, and oxygen levels to optimize biochemical reactions. Biofilms function through microbial communities adhering to surfaces, producing extracellular polymeric substances that protect cells and enable nutrient exchange. The main mechanism difference lies in bioreactors maintaining suspended cells in a controlled environment, whereas biofilms rely on structured surface-associated communities with enhanced resistance and metabolic cooperation.

Applications in Biotechnology

Bioreactors are extensively used in biotechnology for controlled fermentation and large-scale production of pharmaceuticals, enzymes, and biofuels, enabling precise regulation of environmental conditions to maximize microbial or cell growth. Biofilms, on the other hand, find applications in bioremediation and wastewater treatment by facilitating the degradation of pollutants through microbial communities attached to surfaces. Both systems enhance biotechnological processes, with bioreactors optimizing product yield and biofilms providing robust and sustainable microbial activity in complex environments.

Advantages of Bioreactors

Bioreactors offer precise control over environmental conditions such as temperature, pH, and oxygen levels, enhancing microbial growth and metabolite production compared to biofilms. Their scalability and ability to maintain homogeneous mixing improve yield consistency and facilitate industrial-scale processes. Enhanced nutrient supply and waste removal in bioreactors contribute to higher cell densities and productivity relative to biofilm systems.

Advantages of Biofilms

Biofilms offer enhanced microbial stability and resistance to environmental stressors compared to traditional bioreactors, enabling sustained metabolic activity under fluctuating conditions. Their natural matrix promotes efficient substrate retention and gradient formation, enhancing nutrient access and waste removal for microbial communities. This structural complexity leads to improved biocatalytic performance and resilience in wastewater treatment and bioprocessing applications.

Limitations and Challenges

Bioreactors face limitations such as high operational costs, complex scalability issues, and challenges in maintaining optimal environmental conditions for microbial growth. Biofilms present difficulties related to mass transfer limitations, uneven nutrient distribution, and increased resistance to antimicrobial agents, complicating efficient treatment or production processes. Both systems require precise control and monitoring to overcome biofouling, contamination risks, and inconsistent performance outcomes.

Comparative Efficiency and Outcomes

Bioreactors enable controlled environmental conditions to optimize microbial growth and metabolic activity, resulting in higher biomass yield and faster processing times compared to biofilms, which rely on surface-attached microbial communities with limited nutrient diffusion. Biofilms offer enhanced resilience and stability in fluctuating environments, often leading to improved long-term pollutant degradation despite slower initial reaction rates. Efficiency in bioreactors is measured by parameters such as substrate conversion rate and product yield, while biofilms excel in systems requiring resistance to shear stress and sustained microbial activity over extended periods.

Future Trends in Bioprocessing Technologies

Future trends in bioprocessing technologies emphasize integrating bioreactors with biofilm systems to enhance microbial productivity and stability. Advances in continuous flow bioreactors combined with engineered biofilms enable improved substrate utilization and higher biomass retention, essential for sustainable industrial fermentation. Emerging materials and sensor technologies facilitate precise control and monitoring, driving efficiency and scalability in bioprocessing applications.

Bioreactor Infographic

libterm.com

libterm.com