Aerated static pile composting enhances organic waste decomposition by supplying oxygen through a controlled airflow system, optimizing microbial activity and accelerating the breakdown process. This method minimizes labor and turning frequency while maintaining consistent temperature and moisture levels for efficient compost production. Discover how this sustainable technique can improve your composting efforts by exploring the rest of the article.

Table of Comparison

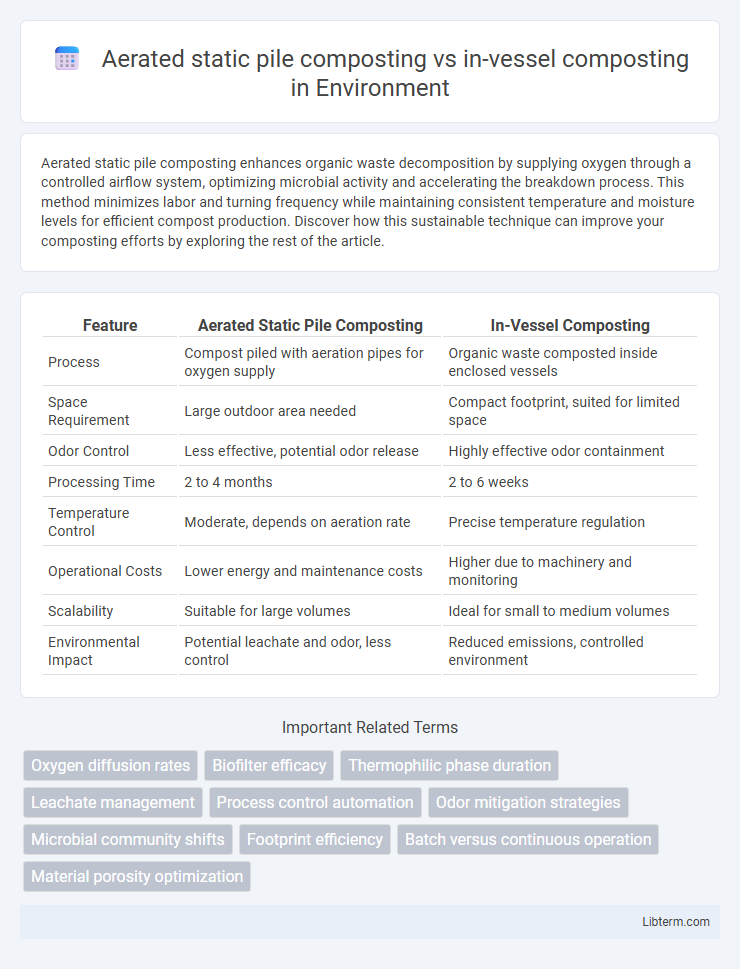

| Feature | Aerated Static Pile Composting | In-Vessel Composting |

|---|---|---|

| Process | Compost piled with aeration pipes for oxygen supply | Organic waste composted inside enclosed vessels |

| Space Requirement | Large outdoor area needed | Compact footprint, suited for limited space |

| Odor Control | Less effective, potential odor release | Highly effective odor containment |

| Processing Time | 2 to 4 months | 2 to 6 weeks |

| Temperature Control | Moderate, depends on aeration rate | Precise temperature regulation |

| Operational Costs | Lower energy and maintenance costs | Higher due to machinery and monitoring |

| Scalability | Suitable for large volumes | Ideal for small to medium volumes |

| Environmental Impact | Potential leachate and odor, less control | Reduced emissions, controlled environment |

Introduction to Aerated Static Pile and In-Vessel Composting

Aerated static pile composting involves managing organic waste in large, porous piles with forced aeration to optimize microbial activity and reduce odors. In-vessel composting confines organic material within a controlled, enclosed environment, allowing precise regulation of temperature, moisture, and oxygen levels for accelerated decomposition. Both methods enhance organic waste management but differ in scalability, operational control, and infrastructure requirements.

Key Differences Between Composting Methods

Aerated static pile composting relies on forced aeration using fans to circulate air through a large pile, enhancing oxygen availability and accelerating decomposition, whereas in-vessel composting confines organic material within a closed container, providing precise control over temperature, moisture, and aeration. Aerated static pile systems are generally suited for larger-scale outdoor operations with moderate equipment investment, while in-vessel composting is ideal for smaller-scale, odor-sensitive, or urban environments requiring faster, more consistent composting cycles. Key differences include the level of environmental control, scalability, odor management, and initial capital costs, with in-vessel composting offering greater process control but higher setup expenses compared to the simpler, bulk aeration approach of aerated static piles.

Environmental Impact Comparison

Aerated static pile composting generates lower greenhouse gas emissions compared to in-vessel composting due to its passive aeration system, which promotes aerobic decomposition. In-vessel composting, while offering better odor control and faster processing times, requires higher energy inputs, contributing to a larger carbon footprint. Lifecycle assessments indicate aerated static pile methods tend to have reduced environmental impacts, especially in large-scale agricultural waste management.

Space and Infrastructure Requirements

Aerated static pile composting requires significantly less infrastructure investment, utilizing open or semi-covered piles with perforated piping systems to ensure airflow, making it suitable for large-scale operations with ample land availability. In-vessel composting demands a considerably smaller footprint due to the enclosed reactors or drum systems, offering controlled environmental conditions and faster processing times but requiring higher initial capital expenditure and advanced infrastructure. Space constraints often favor in-vessel systems in urban or facility-limited environments, whereas aerated static piles are advantageous in rural or industrial settings with expansive land resources.

Process Efficiency and Timeframes

Aerated static pile composting achieves efficient oxygen distribution through forced aeration, promoting microbial activity and reducing composting time to approximately 4-8 weeks. In-vessel composting offers superior control over temperature, moisture, and aeration, leading to faster stabilization times typically within 1-3 weeks. Process efficiency in in-vessel systems is higher due to minimized emissions and space requirements, while aerated static piles provide scalability for larger organic waste volumes.

Odor and Emission Controls

Aerated static pile composting relies on forced aeration to minimize odor and reduce methane emissions by maintaining aerobic conditions throughout the composting mass. In-vessel composting offers superior odor and emission controls due to its enclosed environment, which captures and treats volatile organic compounds (VOCs) and ammonia through biofilters or scrubbers. The controlled temperature and aeration in in-vessel systems further limit greenhouse gas emissions compared to the more open aerated static pile method.

Cost Analysis and Economic Considerations

Aerated static pile composting generally incurs lower initial capital costs compared to in-vessel composting due to simpler infrastructure and minimal mechanical components. In-vessel composting demands higher investment for specialized enclosed reactors and automated control systems but offers faster decomposition rates, potentially reducing operational expenses over time. Operational costs for aerated static pile composting are typically driven by energy use for aeration equipment, while in-vessel systems balance higher maintenance with increased throughput efficiency and better odor control, impacting overall economic viability based on scale and regulatory requirements.

Scalability for Industrial and Community Use

Aerated static pile composting offers scalable solutions for both industrial and community use due to its ability to handle large volumes of organic waste with minimal infrastructure investment, making it suitable for facilities processing several tons per day. In-vessel composting provides a more controlled environment allowing for faster composting cycles and odor management, ideal for urban or space-constrained communities requiring efficient waste processing within limited footprints. Industrial-scale operations benefit from aerated static pile systems for cost-effectiveness and simplicity, while in-vessel systems cater better to community settings demanding stringent environmental controls and diversified organic waste streams.

Quality of Finished Compost Products

Aerated static pile composting produces finished compost with moderate nutrient retention and varying pathogen reduction depending on temperature control, often resulting in less consistent particle size and moisture content. In-vessel composting offers superior quality control, ensuring homogeneous compost with higher nutrient stability, enhanced pathogen kill rates, and optimal moisture levels due to enclosed environment regulation. Consequently, in-vessel composting typically yields a more uniform, nutrient-rich, and mature compost product suitable for sensitive agricultural applications.

Choosing the Right Composting Method

Choosing between aerated static pile (ASP) composting and in-vessel composting depends heavily on factors such as space availability, feedstock type, and process control requirements. ASP composting is ideal for large volumes of organic waste where cost efficiency and oxygen management through forced aeration are priorities, whereas in-vessel composting provides superior environmental control, faster decomposition, and is suited for smaller-scale or odor-sensitive operations. Evaluating operational scale, desired composting speed, and odor control needs ensures selecting the most effective and sustainable composting technology.

Aerated static pile composting Infographic

libterm.com

libterm.com