Biodegradable plastics break down naturally through the action of microorganisms, reducing long-term pollution in landfills and oceans. These materials offer an eco-friendly alternative to traditional plastics by decomposing more quickly and helping conserve environmental resources. Discover how biodegradable plastics can transform waste management and benefit your sustainability efforts in the rest of this article.

Table of Comparison

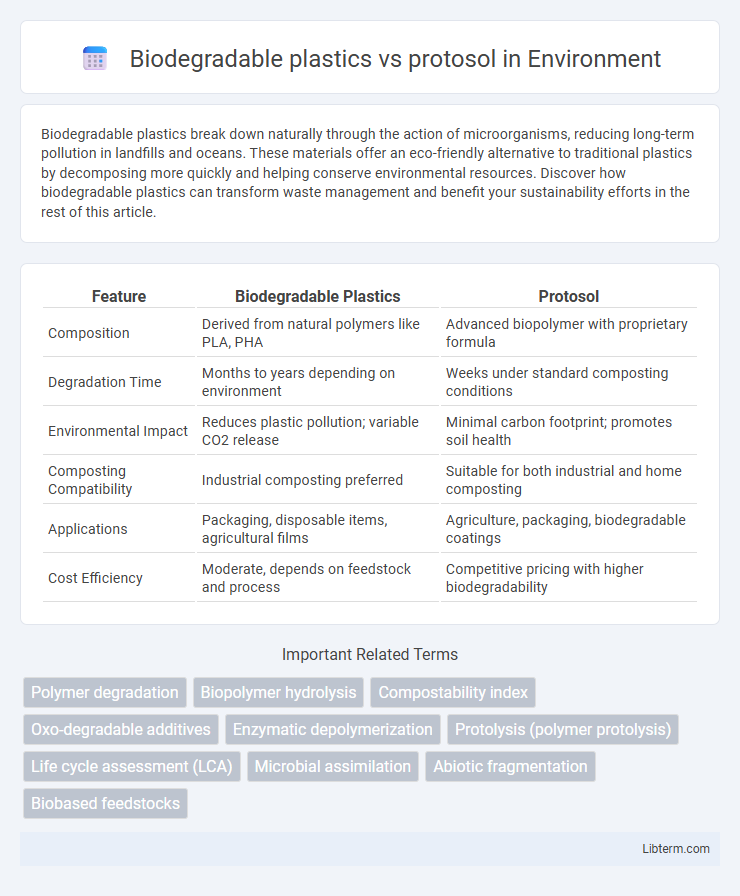

| Feature | Biodegradable Plastics | Protosol |

|---|---|---|

| Composition | Derived from natural polymers like PLA, PHA | Advanced biopolymer with proprietary formula |

| Degradation Time | Months to years depending on environment | Weeks under standard composting conditions |

| Environmental Impact | Reduces plastic pollution; variable CO2 release | Minimal carbon footprint; promotes soil health |

| Composting Compatibility | Industrial composting preferred | Suitable for both industrial and home composting |

| Applications | Packaging, disposable items, agricultural films | Agriculture, packaging, biodegradable coatings |

| Cost Efficiency | Moderate, depends on feedstock and process | Competitive pricing with higher biodegradability |

Introduction to Biodegradable Plastics and Protosol

Biodegradable plastics are designed to break down naturally through microbial activity, reducing environmental impact compared to conventional plastics. Protosol is a novel biodegradable polymer that enhances degradation speed while maintaining durability for industrial applications. Combining innovation and sustainability, Protosol represents a significant advancement in biodegradable plastic technologies.

Defining Biodegradable Plastics

Biodegradable plastics are polymers capable of decomposing naturally through the action of microorganisms, converting into water, carbon dioxide, and biomass, thereby reducing environmental impact compared to conventional plastics. Unlike protosol, which is a specialized soil-conditioning material, biodegradable plastics serve primarily as sustainable packaging or disposable products designed to minimize persistent pollution. Their definition hinges on specific standards such as ASTM D6400 and ISO 14855, which certify the rate and extent of breakdown under industrial composting conditions.

What is Protosol?

Protosol is a patented clear, biodegradable additive designed to enhance the environmental performance of conventional plastics by accelerating their degradation process. Unlike traditional biodegradable plastics, which are formulated to break down inherently, Protosol modifies standard polymers to become more susceptible to microbial activity and environmental factors. This additive helps reduce the accumulation of plastic waste in natural ecosystems by promoting faster disintegration without compromising the material's initial functionality.

Chemical Composition and Manufacturing Processes

Biodegradable plastics are primarily composed of polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHA), derived from renewable biomass sources such as corn starch or sugarcane, and are manufactured through polymerization processes involving fermentation or ring-opening polymerization. Protosol, a specialized solvent blend used in prototyping and precision cleaning, consists mainly of hydrocarbons and proprietary additives, produced through chemical refining and blending techniques. The manufacturing process for biodegradable plastics emphasizes eco-friendly synthesis and biodegradability, whereas protosol production focuses on purity and solvent performance tailored for industrial applications.

Environmental Impact Comparison

Biodegradable plastics break down naturally through microbial activity, significantly reducing long-term environmental pollution and landfill waste. Protosol, a synthetic plastic alternative, often persists longer in ecosystems, contributing to microplastic accumulation and potential toxicity in soil and water. Comparing environmental impacts, biodegradable plastics offer a more sustainable solution by minimizing ecological disruption and accelerating decomposition in natural conditions.

Degradation Rates and Mechanisms

Biodegradable plastics degrade primarily through microbial activity that breaks down polymer chains into carbon dioxide, water, and biomass, with rates varying from weeks to months depending on environmental conditions such as temperature, moisture, and microbial presence. Protosol, a photodegradable additive, accelerates plastic degradation by initiating oxidation under UV exposure, fragmenting the polymer into smaller pieces over months to years but often lacking complete mineralization by microbes. Comparative studies show biodegradable plastics generally achieve faster and more complete degradation through biological mechanisms, while protosol-enhanced plastics rely on abiotic processes that primarily reduce plastic size without full biodegradation.

Advantages of Biodegradable Plastics

Biodegradable plastics offer significant environmental benefits by breaking down naturally through microbial activity, reducing long-term pollution and landfill accumulation compared to traditional plastics like Protosol. They support sustainable waste management by decomposing into water, carbon dioxide, and biomass, minimizing toxic residue commonly associated with Protosol degradation. Their use helps decrease reliance on fossil fuels and lowers greenhouse gas emissions during production and disposal stages.

Benefits and Innovations of Protosol

Protosol offers superior environmental benefits compared to traditional biodegradable plastics by accelerating organic waste conversion into nutrient-rich compost through its advanced microbial technology. Innovations in Protosol include enhanced enzymatic formulations that optimize biodegradation rates without releasing harmful residues, promoting sustainable waste management. This technology supports circular economy efforts by reducing landfill waste and minimizing carbon footprints more effectively than conventional biodegradable materials.

Challenges and Limitations: Biodegradable Plastics vs. Protosol

Biodegradable plastics face challenges such as limited breakdown efficiency in natural environments and reliance on industrial composting facilities, which can hinder widespread environmental benefits. Protosol, while promising as a renewable alternative, encounters limitations related to scalable production costs and inconsistent biodegradation rates under diverse ecological conditions. Both materials require advancements in technology and infrastructure to overcome current barriers and achieve sustainable, large-scale implementation.

Future Prospects and Market Trends

Biodegradable plastics are projected to experience significant market growth driven by increasing environmental regulations and consumer demand for sustainable alternatives, with a compound annual growth rate (CAGR) estimated at around 14% through 2030. Protosol, a specialized biodegradable polymer, is gaining attention for its enhanced degradation properties and compatibility with various applications, positioning it as a competitive player in the eco-friendly materials sector. Innovations in biopolymer formulations and expanding investments in green technologies are expected to further accelerate the adoption of both biodegradable plastics and Protosol in packaging, agriculture, and medical industries.

Biodegradable plastics Infographic

libterm.com

libterm.com