A well-organized warehouse maximizes space efficiency and streamlines inventory management to boost overall productivity. Implementing advanced technologies, such as automated storage and retrieval systems, ensures faster order fulfillment and reduces errors. Discover key strategies to optimize your warehouse operations by reading the full article.

Table of Comparison

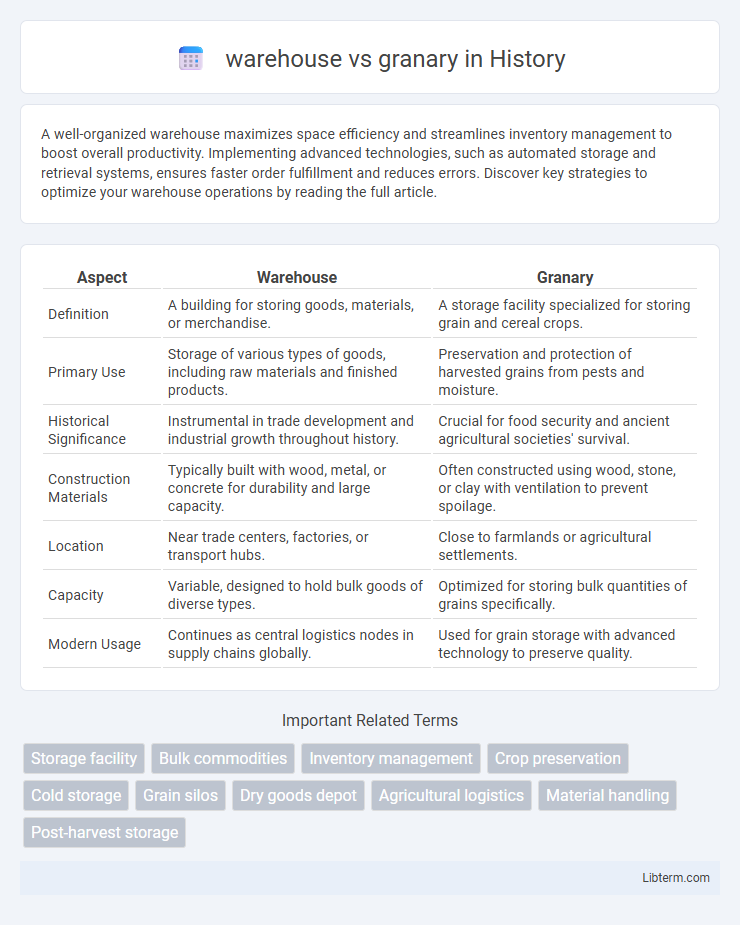

| Aspect | Warehouse | Granary |

|---|---|---|

| Definition | A building for storing goods, materials, or merchandise. | A storage facility specialized for storing grain and cereal crops. |

| Primary Use | Storage of various types of goods, including raw materials and finished products. | Preservation and protection of harvested grains from pests and moisture. |

| Historical Significance | Instrumental in trade development and industrial growth throughout history. | Crucial for food security and ancient agricultural societies' survival. |

| Construction Materials | Typically built with wood, metal, or concrete for durability and large capacity. | Often constructed using wood, stone, or clay with ventilation to prevent spoilage. |

| Location | Near trade centers, factories, or transport hubs. | Close to farmlands or agricultural settlements. |

| Capacity | Variable, designed to hold bulk goods of diverse types. | Optimized for storing bulk quantities of grains specifically. |

| Modern Usage | Continues as central logistics nodes in supply chains globally. | Used for grain storage with advanced technology to preserve quality. |

Introduction: Understanding Warehouses and Granaries

Warehouses store a wide variety of goods, including manufactured products, raw materials, and finished items, while granaries specialize in storing grains like wheat, rice, and corn. Both structures are designed to protect their contents from environmental damage and pests, but granaries emphasize moisture control to preserve seed viability. The distinction lies in their purpose and design, with warehouses catering to diverse inventory management and granaries focusing on agricultural grain preservation.

Definition of Warehouse

A warehouse is a large commercial building designed for storing goods, raw materials, and finished products before distribution or sale. It features specialized infrastructure such as shelving systems, climate control, and loading docks to facilitate efficient inventory management and logistics. Unlike a granary, which specifically stores bulk grains, a warehouse accommodates a diverse range of products across multiple industries.

Definition of Granary

A granary is a specialized storage facility designed specifically for preserving harvested grains like wheat, rice, and corn, ensuring protection from pests, moisture, and contamination. Unlike a general warehouse, which stores a wide variety of goods including machinery, raw materials, and finished products, a granary's structure and materials are optimized to maintain optimal conditions for grain longevity. The design of granaries often includes ventilation systems and elevated flooring to prevent spoilage and maintain grain quality over time.

Core Functions: Storage Purposes Compared

Warehouses primarily store manufactured goods and raw materials to support industrial and commercial activities, emphasizing inventory management and distribution efficiency. Granaries focus specifically on preserving harvested grains, utilizing controlled environments to prevent spoilage and pest infestation. The core function of a warehouse revolves around versatile storage for diverse products, while a granary specializes in maintaining grain quality over extended periods.

Types of Goods Stored: Warehouses vs Granaries

Warehouses primarily store a wide variety of goods including manufactured products, raw materials, machinery, and packaged consumer items, supporting industries like retail, manufacturing, and logistics. Granaries specialize in storing agricultural products, particularly grains such as wheat, rice, corn, and barley, ensuring protection from pests and moisture to maintain quality. The controlled environments in granaries optimize conditions for preserving perishable crops, while warehouses accommodate diverse storage requirements with features like temperature control and shelving systems.

Design and Structure Differences

Warehouses feature robust metal or concrete constructions designed for heavy-duty storage and easy access via loading docks, optimizing space with high ceilings and reinforced flooring to support industrial equipment. Granaries incorporate ventilated, often cylindrical or rectangular silos with temperature and moisture control systems essential for preserving grain quality and preventing spoilage. The structural emphasis in warehouses lies in versatility and load capacity, whereas granaries prioritize airtightness and environmental control to maintain agricultural produce.

Location and Accessibility Considerations

Warehouses are typically situated near urban centers, transportation hubs, or industrial zones to ensure efficient distribution and easy access for trucks, trains, or shipping containers. Granaries are often located closer to agricultural fields or rural areas to facilitate rapid storage of harvested crops and reduce transit time from farms. Accessibility to warehouses prioritizes logistics infrastructure, while granary access emphasizes proximity to farming communities and equipment for handling bulk grains.

Technology and Equipment Used

Warehouses utilize advanced technology such as automated storage and retrieval systems (AS/RS), conveyor belts, and climate control equipment to efficiently handle diverse goods and maintain optimal conditions. Granaries rely on specialized equipment like grain dryers, aeration systems, and moisture sensors designed to preserve the quality of stored cereals and prevent spoilage. Both facilities employ monitoring and control technologies, but warehouses emphasize versatility and automation, while granaries focus on maintaining grain-specific environmental conditions.

Security and Preservation Methods

Warehouses use advanced security systems such as surveillance cameras, access controls, and alarm systems to prevent theft and unauthorized access, while granaries employ physical barriers like thick walls and pest-proof doors to protect stored grains. For preservation, warehouses often implement climate control technologies to regulate temperature and humidity, ensuring optimal storage conditions for diverse products; granaries rely on moisture control, aeration, and regular inspection to prevent mold growth and insect infestation. Both structures prioritize environmental monitoring but adopt specialized methods tailored to the specific nature of their stored goods.

Choosing Between Warehouse and Granary: Key Factors

Selecting between a warehouse and a granary depends on the type of goods stored, moisture control needs, and storage duration. Warehouses are designed for diverse products requiring robust security and space flexibility, while granaries specialize in storing grains with ventilation systems to maintain quality. Evaluating factors like product sensitivity, storage volume, and environmental conditions is essential in making an informed choice.

warehouse Infographic

libterm.com

libterm.com