A plate is a fundamental piece of dinnerware used for serving and presenting food, available in various materials such as ceramic, glass, and plastic. Its design and size can greatly influence the portion and appeal of the meal, making it an essential element in both everyday dining and special occasions. Explore the rest of the article to discover how choosing the right plate can enhance your dining experience.

Table of Comparison

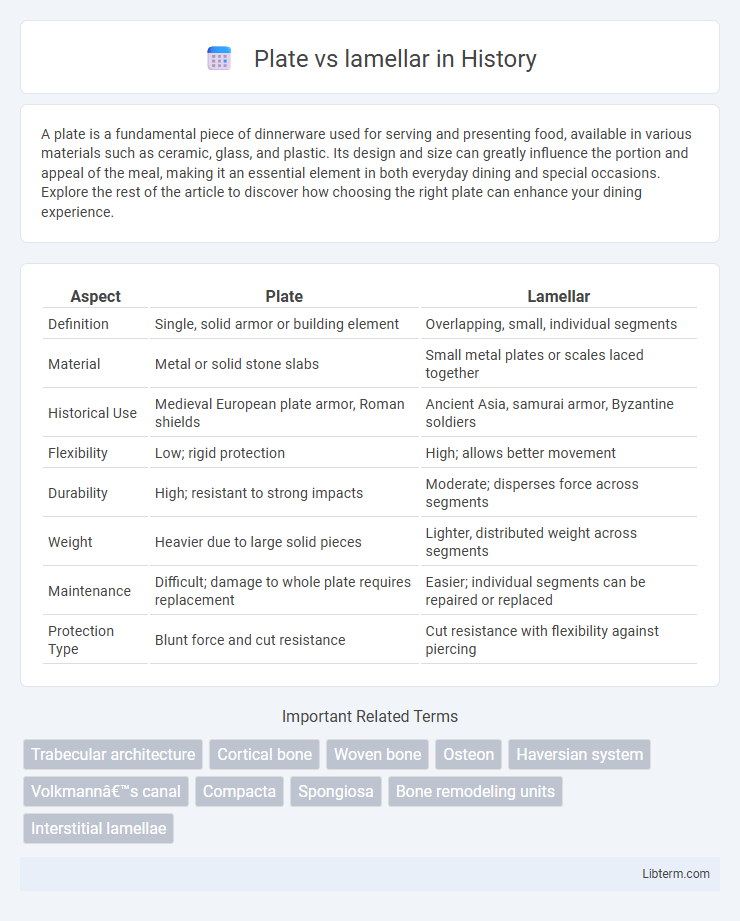

| Aspect | Plate | Lamellar |

|---|---|---|

| Definition | Single, solid armor or building element | Overlapping, small, individual segments |

| Material | Metal or solid stone slabs | Small metal plates or scales laced together |

| Historical Use | Medieval European plate armor, Roman shields | Ancient Asia, samurai armor, Byzantine soldiers |

| Flexibility | Low; rigid protection | High; allows better movement |

| Durability | High; resistant to strong impacts | Moderate; disperses force across segments |

| Weight | Heavier due to large solid pieces | Lighter, distributed weight across segments |

| Maintenance | Difficult; damage to whole plate requires replacement | Easier; individual segments can be repaired or replaced |

| Protection Type | Blunt force and cut resistance | Cut resistance with flexibility against piercing |

Introduction to Plate and Lamellar Structures

Plate structures consist of flat, two-dimensional layers that provide high strength and stiffness in materials like metals and ceramics. Lamellar structures feature alternating layers or lamellae, often found in composites and biological materials, enhancing toughness and resistance to crack propagation. Understanding the differences between plate and lamellar arrangements is crucial for optimizing mechanical properties in engineering and bio-inspired applications.

Definition and Key Differences

Plate structures consist of flat, broad shapes with significant thickness, commonly used in mechanical and structural applications for load distribution. Lamellar structures are composed of thin, stacked layers or plates, often providing enhanced strength and flexibility due to their layered arrangement. Key differences include the geometric form--solid plates versus multiple thin layers--and the resulting mechanical properties, where lamellar designs offer improved resistance to deformation and fracture compared to single plate structures.

Formation Mechanisms

Plate structures form through rapid nucleation and growth in solid-state transformations, where atoms arrange in distinct, parallel layers due to high interface energy and directional solidification. Lamellar structures develop via cooperative growth mechanisms, commonly seen in eutectic or pearlitic transformations, characterized by alternating phases arranged in fine, periodic layers minimizing overall system free energy. The difference in formation mechanisms hinges on atomic diffusion rates and thermodynamic driving forces guiding the microstructural patterning during cooling or thermal treatment.

Material Properties Comparison

Plate structures exhibit higher stiffness and strength due to their two-dimensional geometry, enabling better load distribution compared to lamellar configurations. Lamellar materials, characterized by their stacked, layered morphology, typically offer superior impact resistance and energy absorption because of interlayer sliding mechanisms. The anisotropic mechanical behavior of lamellar materials contrasts with the more isotropic properties of plate structures, influencing their application in aerospace and automotive engineering.

Applications in Industry

Plate and lamellar microstructures exhibit distinct mechanical properties tailored for specific industrial applications. Plate microstructures provide excellent strength and wear resistance, making them ideal for heavy machinery components and cutting tools in manufacturing. Lamellar structures offer enhanced toughness and fatigue resistance, which are critical for aerospace components and automotive parts subjected to cyclic loading.

Advantages of Plate Structures

Plate structures offer superior load distribution due to their ability to resist bending and shear forces efficiently. Their increased stiffness and stability make them ideal for applications requiring high structural integrity and durability. These characteristics result in enhanced performance under dynamic and static loads compared to lamellar structures.

Benefits of Lamellar Structures

Lamellar structures in materials offer enhanced mechanical properties such as increased strength and toughness due to their finely layered microstructure, which inhibits crack propagation effectively. These structures also improve wear resistance and thermal stability, making them ideal for high-performance applications in aerospace and automotive industries. The controlled spacing and orientation of lamellae contribute to superior fatigue resistance and corrosion protection compared to plate-like structures.

Common Materials Exhibiting Plate vs. Lamellar Forms

Common materials exhibiting plate structures include metals like aluminum and copper, which form thin, flat grains enhancing ductility and strength. Lamellar structures are prevalent in alloys such as pearlitic steel and titanium alloys, where alternating layers of different phases improve toughness and wear resistance. Understanding the plate versus lamellar morphology aids in tailoring mechanical properties for aerospace, automotive, and structural applications.

Microstructural Analysis Techniques

Microstructural analysis techniques such as Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM) are critical for distinguishing between plate and lamellar structures in materials. X-ray diffraction (XRD) provides detailed crystallographic information that helps identify the orientation and phase composition unique to plate or lamellar microstructures. Energy Dispersive Spectroscopy (EDS) coupled with electron microscopy enhances elemental mapping, enabling precise characterization of microstructural features and their distribution in plate versus lamellar morphologies.

Future Trends and Research Directions

Future trends in plate versus lamellar microstructures emphasize advanced computational modeling to predict mechanical performance and optimize material properties. Research directions focus on nano-engineered composites and additive manufacturing techniques to enhance the strength-to-weight ratio and thermal stability of plate and lamellar phases. Emerging studies explore in-situ characterization methods for real-time monitoring of microstructural evolution under dynamic loading conditions.

Plate Infographic

libterm.com

libterm.com