Elastic technology offers unparalleled flexibility and scalability, making it essential for businesses aiming to adapt quickly to changing demands. Its powerful search and analytics capabilities enable you to derive actionable insights from vast amounts of data in real-time. Explore the rest of this article to discover how Elastic can transform your data management strategy.

Table of Comparison

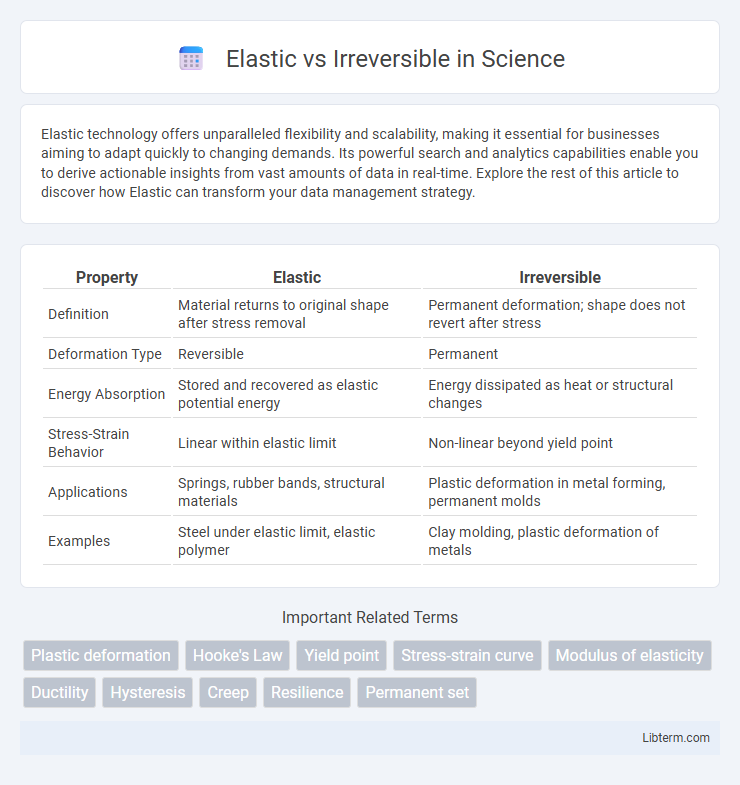

| Property | Elastic | Irreversible |

|---|---|---|

| Definition | Material returns to original shape after stress removal | Permanent deformation; shape does not revert after stress |

| Deformation Type | Reversible | Permanent |

| Energy Absorption | Stored and recovered as elastic potential energy | Energy dissipated as heat or structural changes |

| Stress-Strain Behavior | Linear within elastic limit | Non-linear beyond yield point |

| Applications | Springs, rubber bands, structural materials | Plastic deformation in metal forming, permanent molds |

| Examples | Steel under elastic limit, elastic polymer | Clay molding, plastic deformation of metals |

Introduction to Elastic and Irreversible Behavior

Elastic behavior refers to a material's ability to deform under stress and return to its original shape once the stress is removed, characterized by reversible strain within the elastic limit. Irreversible behavior involves permanent deformation where the material does not regain its initial configuration after the removal of stress, often resulting from plastic deformation or damage beyond the elastic threshold. Understanding these fundamental differences is crucial for applications in material science and structural engineering to predict performance and failure modes.

Defining Elastic Deformation

Elastic deformation refers to the reversible change in the shape or size of a material when subjected to stress, where the material returns to its original form once the applied force is removed. This phenomenon is governed by Hooke's Law, stating that stress is proportional to strain within the elastic limit. Unlike irreversible deformation, elastic deformation does not cause permanent structural changes or damage to the material.

Understanding Irreversible (Plastic) Deformation

Irreversible deformation, also known as plastic deformation, occurs when a material is stressed beyond its elastic limit, causing permanent shape change even after the applied force is removed. This phenomenon is critical in engineering as it dictates the material's yield strength and failure point, influencing design safety and durability. Unlike elastic deformation, which is fully recoverable, plastic deformation involves dislocation movements within the material's crystal structure, leading to permanent atomic rearrangement.

Key Differences: Elastic vs Irreversible

Elastic materials return to their original shape after deformation due to their ability to store and release strain energy, while irreversible materials undergo permanent deformation or damage when stressed beyond their elastic limit. Elastic behavior is characterized by a linear stress-strain relationship within the elastic limit, whereas irreversible deformation involves plastic or permanent changes to the material's microstructure. The key difference lies in the recoverability of shape: elastic materials exhibit full recovery, whereas irreversible materials do not regain their initial form after unloading.

Real-World Examples of Elastic Materials

Elastic materials like rubber bands and springs exhibit reversible deformation, returning to their original shape after stress is removed, which contrasts with irreversible materials such as clay or plasticine that permanently deform. Natural rubber, used in automotive tires and flexible seals, demonstrates high elasticity by stretching under pressure and recovering without damage, essential for durability and performance. Similarly, steel springs in mechanical watches and suspension systems rely on elastic properties to maintain functionality through continuous cyclic loading and unloading.

Real-World Examples of Irreversible Changes

Irreversible changes in the real world include the burning of fossil fuels, which transforms coal and oil into carbon dioxide, permanently altering their chemical structure and contributing to climate change. Biological examples like cell death or hair bleaching result in non-reversible alterations at the molecular or structural level. Geological processes such as volcanic eruptions permanently reshape landscapes through the deposition of lava and ash, illustrating irreversible physical transformations.

Factors Influencing Elastic and Irreversible Responses

Elastic responses depend on material properties such as Young's modulus, temperature, and strain rate, allowing the material to return to its original shape after deformation. Irreversible responses occur when stress exceeds the yield strength or when plastic deformation, creep, or fatigue occurs, leading to permanent changes in the material's microstructure. Environmental factors like humidity, chemical exposure, and loading duration also significantly influence whether a material exhibits elastic or irreversible behavior.

Importance in Material Selection and Engineering

Elastic materials return to their original shape after deformation, making them essential in applications requiring repeated stress cycles and durability, such as springs and flexible components. Irreversible, or plastic, deformation indicates permanent shape change, critical for processes like metal forming and structural components where reshaping or energy absorption is necessary. Selecting materials based on elasticity versus plasticity directly impacts product lifespan, performance under load, and safety in engineering design and manufacturing.

Testing Methods for Elastic and Irreversible Properties

Testing methods for elastic properties typically involve stress-strain analysis using techniques like tensile, compression, and cyclic loading tests to measure material deformation and recovery. Irreversible properties are evaluated through plastic deformation tests, creep testing, and hardness measurements that quantify permanent changes after applied stresses exceed elastic limits. Advanced methods such as dynamic mechanical analysis (DMA) and nanoindentation provide precise data on both reversible elastic behavior and irreversible structural changes at micro and nano scales.

Conclusion: Choosing Elastic or Irreversible Based on Application

Choosing between elastic and irreversible materials depends on the specific application requirements such as flexibility, durability, and load conditions. Elastic materials are ideal for applications needing repeated deformation and recovery, including springs, rubber seals, and flexible electronics. Irreversible materials suit uses where permanent shape change or damage resistance is critical, like structural adhesives, thermal bonding, and crash components.

Elastic Infographic

libterm.com

libterm.com