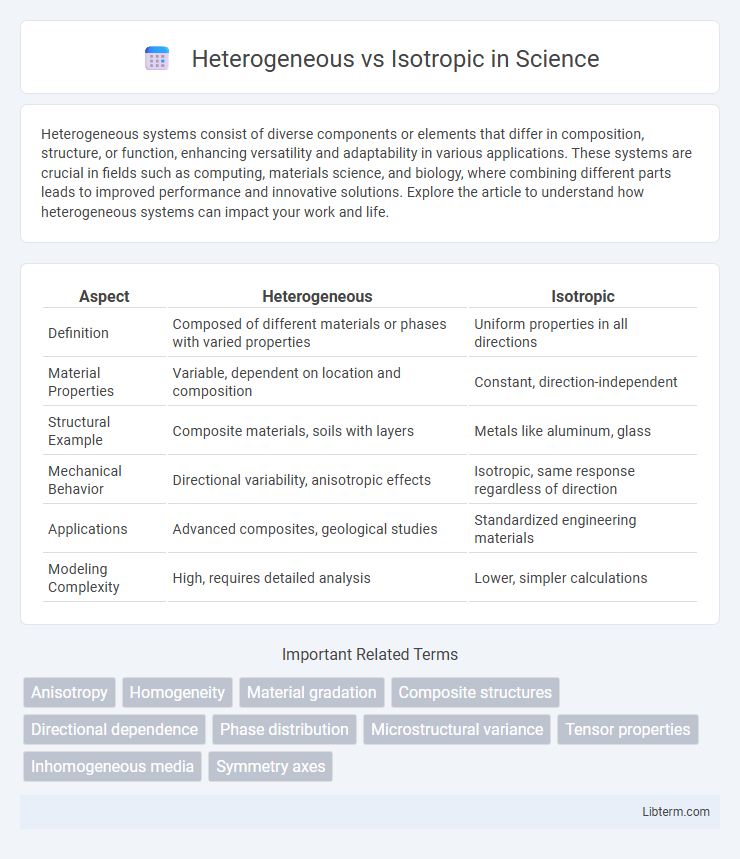

Heterogeneous systems consist of diverse components or elements that differ in composition, structure, or function, enhancing versatility and adaptability in various applications. These systems are crucial in fields such as computing, materials science, and biology, where combining different parts leads to improved performance and innovative solutions. Explore the article to understand how heterogeneous systems can impact your work and life.

Table of Comparison

| Aspect | Heterogeneous | Isotropic |

|---|---|---|

| Definition | Composed of different materials or phases with varied properties | Uniform properties in all directions |

| Material Properties | Variable, dependent on location and composition | Constant, direction-independent |

| Structural Example | Composite materials, soils with layers | Metals like aluminum, glass |

| Mechanical Behavior | Directional variability, anisotropic effects | Isotropic, same response regardless of direction |

| Applications | Advanced composites, geological studies | Standardized engineering materials |

| Modeling Complexity | High, requires detailed analysis | Lower, simpler calculations |

Introduction to Heterogeneous and Isotropic Materials

Heterogeneous materials consist of multiple distinct phases or components with varying physical or chemical properties, resulting in non-uniform composition and behavior. In contrast, isotropic materials exhibit uniform properties in all directions due to their homogeneous structure. Understanding these differences is crucial in fields like materials science and engineering, where material performance depends on anisotropy and phase distribution.

Defining Heterogeneous Materials

Heterogeneous materials consist of multiple distinct phases or components with varying properties distributed unevenly throughout the material, resulting in non-uniform composition and behavior. These materials contrast with isotropic materials, which exhibit consistent properties in all directions due to their uniform structure. Examples of heterogeneous materials include composites, concrete, and biological tissues, where microscopic differences influence macroscopic mechanical, thermal, or electrical performance.

Understanding Isotropic Materials

Isotropic materials exhibit uniform properties in all directions, making their mechanical, thermal, and optical characteristics predictable and consistent regardless of the orientation. Unlike heterogeneous materials, which possess varying compositions or structures that lead to directional dependency, isotropic materials provide simplicity in analysis and application. Understanding isotropy is essential for optimizing material selection in engineering fields where homogeneity and direction-independent behavior are critical.

Key Differences: Heterogeneous vs Isotropic

Heterogeneous materials exhibit variations in composition or structure throughout their volume, causing different properties in different regions, whereas isotropic materials possess uniform properties in all directions due to their consistent internal structure. Key differences include anisotropy in heterogeneous materials leading to direction-dependent mechanical, thermal, or electrical behavior, while isotropic materials maintain uniform responses regardless of direction. This distinction significantly impacts material selection and performance in engineering applications, such as composite materials versus metals.

Mechanical Properties Comparison

Heterogeneous materials exhibit varied mechanical properties across different regions due to their non-uniform composition, leading to anisotropy in strength, stiffness, and deformation behavior. In contrast, isotropic materials demonstrate uniform mechanical properties in all directions, providing predictable and consistent performance under stress. This fundamental difference influences the design and application of materials in engineering, where heterogeneous materials are often tailored for specific load-bearing capabilities, while isotropic materials offer reliability in uniform stress environments.

Applications in Engineering and Technology

Heterogeneous materials exhibit varying properties within their structure, enabling tailored applications in composite materials for aerospace and civil engineering where strength-to-weight ratios are crucial. Isotropic materials maintain uniform properties in all directions, making them ideal for components requiring consistent performance, such as metal sheets in automotive manufacturing and optical lenses in telecommunications. Engineering applications leverage the directional characteristics of heterogeneous materials for load-bearing efficiency while relying on isotropic materials for predictable stress distribution and durability.

Advantages and Disadvantages

Heterogeneous materials exhibit varied properties across different regions, offering advantages like tailored mechanical strength and improved thermal resistance, but they may suffer from issues like structural weaknesses and complex manufacturing processes. Isotropic materials have uniform properties in all directions, which simplifies design and ensures consistent performance but can limit customization and optimization for specific applications. Selecting between heterogeneous and isotropic materials depends on the balance between desired property variation and manufacturing feasibility.

Case Studies and Real-World Examples

Heterogeneous materials exhibit varying properties across different regions, as seen in composite aircraft components combining carbon fiber and resin for optimized strength and weight. Isotropic materials like steel show uniform properties regardless of direction, widely used in construction for consistent mechanical performance in buildings and bridges. Case studies in aerospace and civil engineering highlight how material selection based on heterogeneity or isotropy impacts durability, safety, and efficiency in real-world applications.

Material Selection Considerations

Material selection for heterogeneous composites involves evaluating properties that vary spatially, such as strength and thermal conductivity, to ensure performance under diverse loading conditions. Isotropic materials, characterized by uniform properties in all directions, simplify design criteria but may limit optimization for specific applications requiring directional strength. Engineers prioritize anisotropy metrics, phase distribution, and compatibility with manufacturing processes when choosing between heterogeneous and isotropic materials.

Future Trends in Material Science

Future trends in material science emphasize the development of heterogeneous materials with tailored microstructures to achieve superior mechanical, thermal, and electrical properties compared to isotropic materials. Advanced techniques such as additive manufacturing and nanoscale engineering enable precise control over anisotropy to enhance performance in aerospace, electronics, and biomedical applications. Machine learning models are increasingly applied to predict and optimize the behavior of heterogeneous composites, accelerating innovation beyond traditional isotropic material designs.

Heterogeneous Infographic

libterm.com

libterm.com