Plastic is a versatile material widely used in packaging, construction, and everyday products due to its durability and lightweight properties. Its environmental impact, however, raises significant concerns about pollution and waste management. Explore the rest of this article to understand how plastic affects your world and the innovations aimed at reducing its footprint.

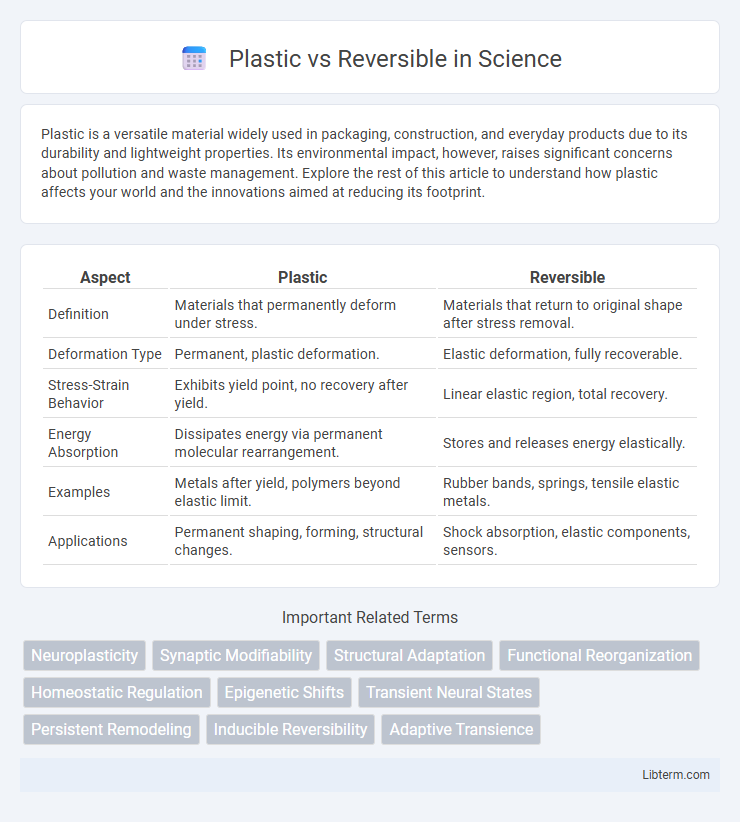

Table of Comparison

| Aspect | Plastic | Reversible |

|---|---|---|

| Definition | Materials that permanently deform under stress. | Materials that return to original shape after stress removal. |

| Deformation Type | Permanent, plastic deformation. | Elastic deformation, fully recoverable. |

| Stress-Strain Behavior | Exhibits yield point, no recovery after yield. | Linear elastic region, total recovery. |

| Energy Absorption | Dissipates energy via permanent molecular rearrangement. | Stores and releases energy elastically. |

| Examples | Metals after yield, polymers beyond elastic limit. | Rubber bands, springs, tensile elastic metals. |

| Applications | Permanent shaping, forming, structural changes. | Shock absorption, elastic components, sensors. |

Introduction to Plastic and Reversible Materials

Plastic materials consist of synthetic polymers that are lightweight, durable, and moldable, making them prevalent in packaging, automotive, and consumer goods industries. Reversible materials, often thermoplastics, can be repeatedly melted and reshaped without significant degradation, enabling recycling and sustainability in manufacturing processes. The distinction between plastic types heavily influences environmental impact, resource efficiency, and circular economy practices.

Defining Plastic: Properties and Uses

Plastic is a synthetic material composed of polymers that exhibit versatility, durability, and resistance to chemicals and moisture, making them ideal for a wide range of applications from packaging to automotive parts. Their lightweight nature and ability to be molded into various shapes support mass production and customization in industries such as electronics, construction, and medical devices. Common types include polyethylene, polypropylene, and polyvinyl chloride, each offering distinct mechanical and thermal properties tailored to specific functional requirements.

Understanding Reversible Materials: An Overview

Reversible materials, unlike traditional plastics, possess the unique ability to undergo multiple cycles of transformation without degradation, enabling sustainable reuse and recycling. These materials often include thermoplastics, shape-memory polymers, and certain bio-based substances that respond to environmental stimuli such as heat or light to return to their original state. Emphasizing reversible materials supports circular economy models by reducing waste and conserving resources through enhanced lifecycle management.

Environmental Impact: Plastic vs Reversible Alternatives

Plastic products contribute significantly to environmental pollution, with millions of tons of plastic waste accumulating in oceans and landfills every year, causing long-term damage to ecosystems and wildlife. Reversible alternatives, such as reusable bags, containers, and packaging, reduce waste generation and resource consumption by enabling multiple uses and minimizing single-use disposal. Choosing reversible options decreases carbon emissions and plastic pollution, promoting sustainability and environmental health through reduced landfill burden and resource conservation.

Cost Comparison: Economic Factors

Plastic repairs generally incur lower upfront costs due to inexpensive materials and simpler processes, making them more budget-friendly for short-term fixes. Reversible alternatives often involve higher initial expenses because they require specialized materials and techniques designed for sustainability and reusability. Evaluating long-term economic factors, reversible solutions can reduce costs over time by minimizing waste and enabling multiple uses, offering better value despite the initial investment.

Durability and Lifespan Analysis

Plastic materials offer a wide range of durability depending on their composition, but they typically degrade over time due to exposure to UV light, chemicals, and physical stress, resulting in a lifespan that can vary from a few years to several decades. Reversible materials, designed for reuse and repair, provide enhanced durability by allowing components to be restored or replaced, significantly extending their functional lifespan and reducing waste. This durability and lifespan analysis highlights that while plastics are often disposable, reversible materials present sustainable solutions through their potential for longevity and environmental impact reduction.

Recyclability and Waste Management

Reversible materials offer superior recyclability compared to conventional plastics, as they can be broken down and reformed without loss of quality, reducing landfill accumulation. Plastic waste often ends up in incinerators or landfills due to contamination and limited recycling facilities, complicating waste management efforts. Emphasizing reversible materials supports a circular economy by enhancing resource recovery and minimizing environmental pollution.

Applications in Industry: Where Each Excels

Plastic materials dominate industries requiring lightweight, durable, and cost-effective solutions such as packaging, automotive components, and consumer electronics due to their moldability and resistance to corrosion. Reversible materials, including shape-memory alloys and thermoplastics, excel in applications demanding adaptability and reusability like medical devices, adaptable aerospace parts, and sustainable fashion, enabling repeated reshaping without degradation. The choice between plastic and reversible materials hinges on factors like lifecycle sustainability, mechanical performance, and specific industry requirements.

Consumer Perspectives: Preferences and Trends

Consumers increasingly prioritize sustainability, driving demand for reversible products that reduce waste compared to traditional plastic items. Preference shifts toward recyclable, reusable materials reflect growing awareness of environmental impact and health concerns associated with plastic use. Market trends highlight a rise in eco-friendly alternatives, influencing brand strategies and product development to align with consumer values on durability and circular economy principles.

Future Outlook: Innovations and Sustainability

Innovations in reversible plastics focus on enhancing material recyclability, reducing environmental impact through chemical recycling and biodegradable additives. Advanced polymer engineering enables the design of reversible plastics that can be repeatedly processed without degradation, promoting circular economy models. Sustainability efforts prioritize the development of eco-friendly reversible plastics to replace conventional plastics, drastically cutting carbon footprints and plastic waste in future markets.

Plastic Infographic

libterm.com

libterm.com