Brittle materials are prone to breaking or cracking under stress without significant deformation, making them vulnerable in structural applications. Understanding brittleness helps you choose the right materials for durability and safety in engineering projects. Discover more about how brittleness affects material performance in the full article.

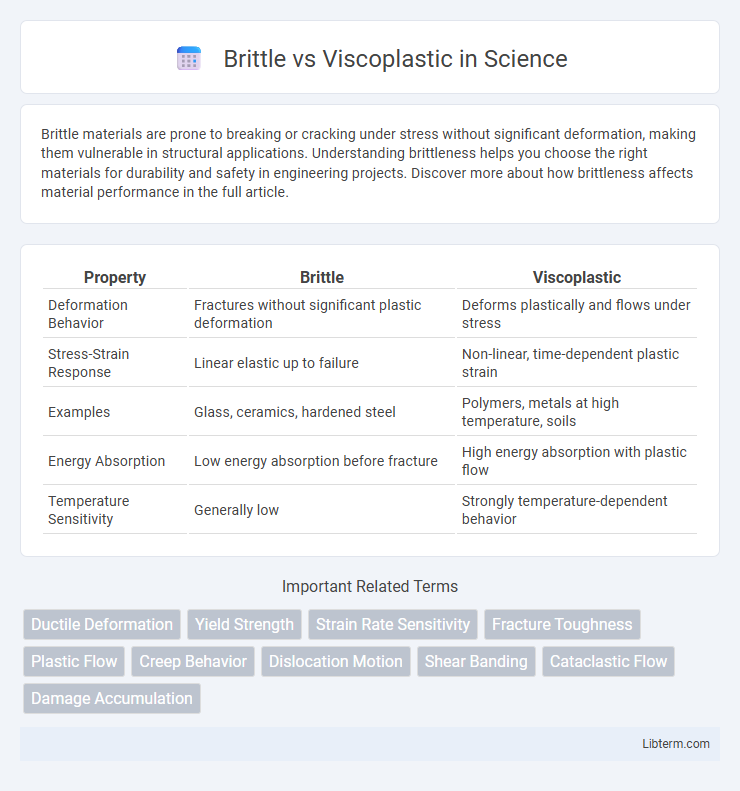

Table of Comparison

| Property | Brittle | Viscoplastic |

|---|---|---|

| Deformation Behavior | Fractures without significant plastic deformation | Deforms plastically and flows under stress |

| Stress-Strain Response | Linear elastic up to failure | Non-linear, time-dependent plastic strain |

| Examples | Glass, ceramics, hardened steel | Polymers, metals at high temperature, soils |

| Energy Absorption | Low energy absorption before fracture | High energy absorption with plastic flow |

| Temperature Sensitivity | Generally low | Strongly temperature-dependent behavior |

Introduction to Brittle and Viscoplastic Behavior

Brittle behavior in materials is characterized by sudden fracture without significant prior deformation, often occurring in ceramics and certain metals at low temperatures. Viscoplastic behavior involves time-dependent plastic deformation under stress, typical in polymers and metals at elevated temperatures, combining viscosity and plasticity effects. Understanding these distinct mechanical responses is crucial for selecting materials in applications requiring specific strength and deformation characteristics.

Defining Brittle Materials

Brittle materials are characterized by their inability to undergo significant plastic deformation before fracture, typically breaking suddenly under stress. These materials, such as glass, ceramics, and some cast irons, exhibit low toughness and high hardness, making them susceptible to crack propagation. Understanding the brittle behavior is crucial for applications requiring high strength but low ductility, where failure can occur without noticeable prior deformation.

Understanding Viscoplastic Materials

Viscoplastic materials exhibit time-dependent deformation under stress, combining characteristics of viscosity and plasticity that differentiate them from brittle materials, which fracture with minimal deformation. The understanding of viscoplastic behavior involves analyzing strain rate sensitivity and irreversible flow that occurs once the yield stress is exceeded. This knowledge is essential for predicting long-term material performance in applications involving high temperatures or sustained loads.

Key Differences Between Brittle and Viscoplastic Deformation

Brittle deformation occurs when materials fracture or crack under stress without significant plastic deformation, typically at low temperatures or high strain rates, and involves sudden failure. Viscoplastic deformation involves time-dependent, irreversible plastic flow where materials deform gradually under sustained stress, often observed in metals and polymers at elevated temperatures. Key differences include the nature of strain--elastic and sudden in brittle materials versus continuous and rate-dependent in viscoplastic materials--and the energy absorption capacity before failure, which is minimal in brittle deformation and substantial in viscoplastic deformation.

Stress-Strain Characteristics: Brittle vs. Viscoplastic

Brittle materials exhibit a linear stress-strain curve up to the point of fracture, with minimal plastic deformation, resulting in sudden failure after elastic limit is reached. Viscoplastic materials show a nonlinear stress-strain behavior characterized by time-dependent strain and gradual yielding, allowing for significant plastic deformation before complete failure. The key distinction lies in viscoplastic materials' ability to undergo creep and stress relaxation, contrasting with the instantaneous fracture typical of brittle materials.

Common Examples of Brittle and Viscoplastic Materials

Common examples of brittle materials include glass, ceramics, and cast iron, known for their low ductility and sudden fracture under stress. Viscoplastic materials, such as polymers like polyethylene and metals like lead, exhibit time-dependent deformation under applied stress, combining viscous and plastic behavior. These distinctions influence material selection in industries where flexibility or rigidity is crucial for performance and safety.

Factors Influencing Brittle and Viscoplastic Responses

Material temperature, strain rate, and microstructural features significantly influence brittle and viscoplastic responses. Brittle materials typically fail at low temperatures and high strain rates due to limited atomic mobility, while viscoplastic behavior dominates at elevated temperatures and low strain rates where time-dependent deformation mechanisms activate. Grain size, phase distribution, and defect density also critically determine whether a material exhibits brittle fracture or viscoplastic flow under mechanical loading.

Applications in Engineering and Industry

Brittle materials, such as ceramics and glass, are widely used in applications requiring high compressive strength and wear resistance, like cutting tools and structural components in aerospace. Viscoplastic materials, including metals and polymers, are preferred in industries demanding energy absorption and deformation capacity, such as automotive crash zones and metal forming processes. Understanding the distinct deformation behaviors of brittle and viscoplastic materials enables engineers to optimize design for durability, safety, and performance in various industrial applications.

Testing Methods for Brittle and Viscoplastic Behavior

Testing methods for brittle behavior often rely on fracture toughness tests such as the Charpy impact test and the three-point bending test to assess material resistance to crack propagation under sudden loading. Viscoplastic behavior is commonly evaluated through creep tests and stress relaxation experiments, which measure time-dependent deformation under constant stress or strain. Instrumented indentation and cyclic loading tests can also characterize both behaviors by revealing differences in material response under varying strain rates and temperatures.

Conclusion: Choosing the Right Material for Your Needs

Selecting between brittle and viscoplastic materials depends heavily on the application's stress conditions and deformation requirements. Brittle materials offer high strength but fracture easily under tensile stress, making them ideal for load-bearing applications with minimal deformation. Viscoplastic materials provide superior ductility and energy absorption through time-dependent deformation, suited for environments requiring resistance to impact and dynamic stresses.

Brittle Infographic

libterm.com

libterm.com