Replacement involves swapping out a faulty or outdated component with a new one to restore optimal function. Whether it's in machinery, technology, or everyday items, timely replacement can prevent further damage and enhance efficiency. Discover how strategic replacement can save you time and money by reading the rest of the article.

Table of Comparison

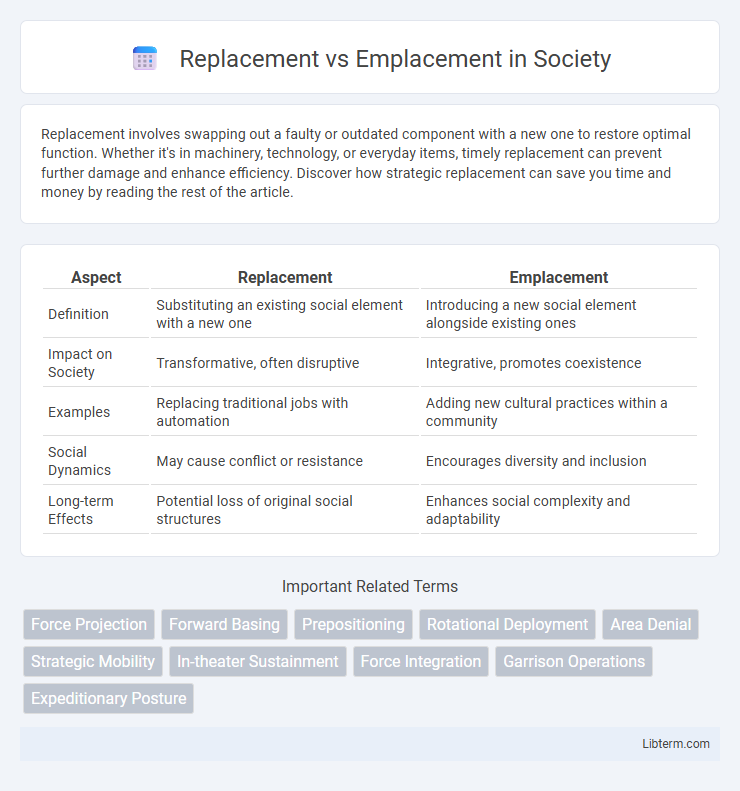

| Aspect | Replacement | Emplacement |

|---|---|---|

| Definition | Substituting an existing social element with a new one | Introducing a new social element alongside existing ones |

| Impact on Society | Transformative, often disruptive | Integrative, promotes coexistence |

| Examples | Replacing traditional jobs with automation | Adding new cultural practices within a community |

| Social Dynamics | May cause conflict or resistance | Encourages diversity and inclusion |

| Long-term Effects | Potential loss of original social structures | Enhances social complexity and adaptability |

Understanding Replacement and Emplacement: Key Differences

Replacement involves removing an existing object or component and installing a new one in its place, often to restore functionality or improve performance. Emplacement refers to the strategic positioning or installation of an object, typically in a permanent or semi-permanent location, without necessarily removing what was there before. Key differences include the intent behind the action--replacement targets substitution and renewal, while emplacement focuses on placement and stability within a specific environment.

Historical Context: Evolution of Replacement and Emplacement

Replacement and emplacement strategies have evolved significantly throughout military history, reflecting changes in warfare technology, tactics, and organizational structures. Early military formations relied on straightforward replacement to fill gaps in ranks, while modern forces incorporate complex emplacement techniques to optimize battlefield positioning and resource allocation. The shift from linear mass infantry tactics to combined arms and mechanized warfare underscores the growing importance of emplacement in achieving strategic advantage.

When to Choose Replacement Over Emplacement

Choose replacement over emplacement when an object needs to be updated or entirely swapped out, especially if it already exists in a container or data structure. Replacement is ideal when performance impact is minimal and when the current object's state is no longer valid or useful. Emplacement should be avoided if the object requires reinitialization or if maintaining container integrity through direct construction is unnecessary.

Benefits of Replacement: Pros and Cons

Replacement ensures updated technology and improved efficiency by substituting outdated components completely, reducing downtime and maintenance costs while enhancing system reliability. However, this approach can involve higher initial investment and potential compatibility issues with existing infrastructure. Despite these drawbacks, replacement often leads to long-term savings through increased performance and reduced operational risks.

Advantages of Emplacement: Pros and Cons

Emplacement offers significant advantages such as precise positioning and enhanced durability because components are directly integrated into their designated locations, reducing movement and wear over time. This method improves thermal management and structural stability, particularly in high-stress environments like heavy machinery and aerospace applications. However, emplacement can entail higher initial costs and complexity in assembly compared to replacement, which remains simpler for maintenance and quick fixes.

Cost Analysis: Replacement vs Emplacement

Cost analysis between replacement and emplacement reveals significant differences in initial investment and long-term expenses. Replacement often incurs higher upfront costs due to new materials and labor, but can result in lower maintenance expenses if modern technologies are utilized. Emplacement typically requires less capital initially but may lead to increased operational and repair costs over time, impacting overall cost efficiency.

Environmental Impact: Replacement versus Emplacement

Replacement of existing infrastructure often involves demolition and waste generation, leading to significant environmental impacts such as increased carbon emissions and landfill use. Emplacement typically minimizes disruption by integrating new components with existing systems, reducing resource consumption and environmental degradation. Life cycle assessments indicate emplacement strategies generally result in lower overall ecological footprints compared to replacement projects.

Industry Applications: Where Each Method Excels

Emplacement excels in heavy industries requiring precise positioning of large, heavy components such as shipbuilding, aerospace assembly, and nuclear power plant construction due to its ability to place parts directly at their final location. Replacement is preferred in automotive manufacturing and heavy machinery maintenance where parts are removed and substituted rapidly to minimize downtime and maintain production efficiency. Industry applications leverage emplacement for initial complex setups and replacement for ongoing maintenance and part upgrades to optimize operational workflows.

Common Challenges and Solutions in Replacement and Emplacement

Replacement and emplacement both face challenges such as environmental disruption, logistical complexity, and high costs, often requiring specialized equipment and expert planning to ensure successful execution. Common solutions include thorough site assessments, use of advanced technology for precise installation, and adherence to sustainable practices to minimize ecological impact. Streamlined project management and proactive stakeholder communication further mitigate risks and enhance operational efficiency in both approaches.

Future Trends: Replacement vs Emplacement in Modern Practice

Future trends in modern practice emphasize increasing adoption of emplacement techniques over replacement due to enhanced precision and reduced operational downtime. Advanced sensor integration and automated deployment systems facilitate real-time monitoring and adaptive emplacement strategies, optimizing maintenance schedules and extending equipment lifespan. Emplacement methods also support sustainable practices by minimizing material waste and environmental impact compared to traditional replacement processes.

Replacement Infographic

libterm.com

libterm.com