Industrial modernization drives increased efficiency and innovation by integrating advanced technologies such as automation, artificial intelligence, and IoT into manufacturing processes. These improvements reduce operational costs, enhance product quality, and boost overall competitiveness in the global market. Discover how industrial modernization can transform your business by reading further.

Table of Comparison

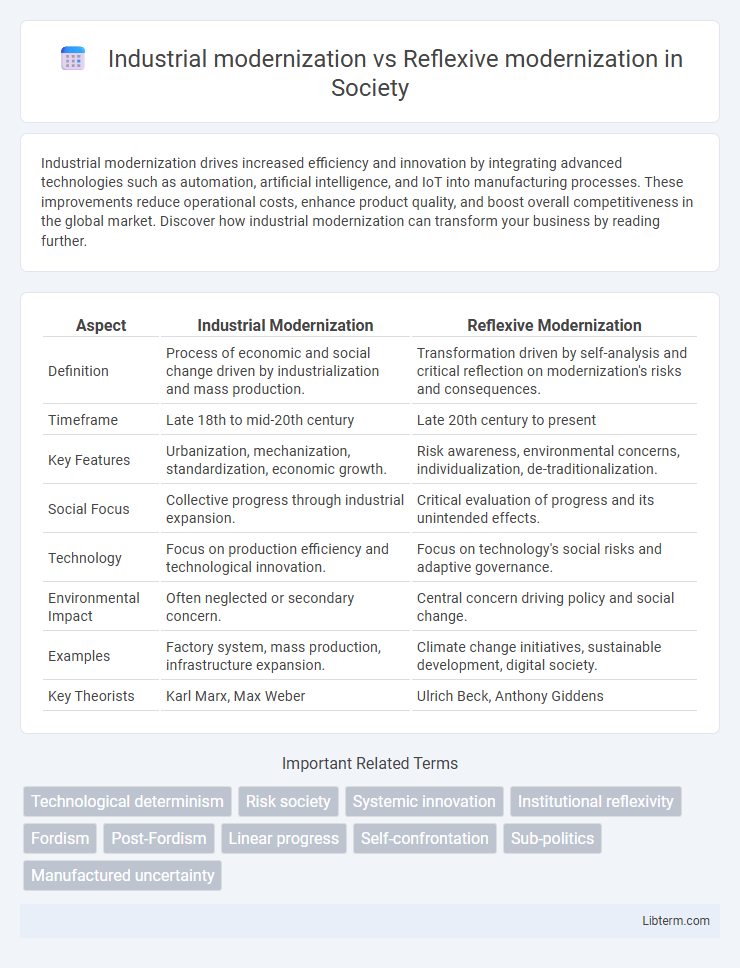

| Aspect | Industrial Modernization | Reflexive Modernization |

|---|---|---|

| Definition | Process of economic and social change driven by industrialization and mass production. | Transformation driven by self-analysis and critical reflection on modernization's risks and consequences. |

| Timeframe | Late 18th to mid-20th century | Late 20th century to present |

| Key Features | Urbanization, mechanization, standardization, economic growth. | Risk awareness, environmental concerns, individualization, de-traditionalization. |

| Social Focus | Collective progress through industrial expansion. | Critical evaluation of progress and its unintended effects. |

| Technology | Focus on production efficiency and technological innovation. | Focus on technology's social risks and adaptive governance. |

| Environmental Impact | Often neglected or secondary concern. | Central concern driving policy and social change. |

| Examples | Factory system, mass production, infrastructure expansion. | Climate change initiatives, sustainable development, digital society. |

| Key Theorists | Karl Marx, Max Weber | Ulrich Beck, Anthony Giddens |

Introduction to Modernization Theories

Industrial modernization emphasizes the transformation of economies through mechanization, urbanization, and increased production efficiency, reflecting the shift from agrarian societies to industrial powerhouses. Reflexive modernization centers on the self-critical nature of modern societies that continuously adapt by questioning traditional structures, risks, and innovations while reshaping social and cultural norms. These contrasting theories outline the evolution of modernization, highlighting its empirical roots in industrial growth versus the sociological focus on change driven by constant reflexivity.

Defining Industrial Modernization

Industrial modernization refers to the transformation of traditional industries through the adoption of advanced technologies, mechanization, and streamlined production processes to increase efficiency and output. It emphasizes large-scale infrastructure development, standardized manufacturing, and the integration of factory systems to drive economic growth and societal progress. This form of modernization contrasts with reflexive modernization, which focuses on the critical assessment and restructuring of modernity's social and environmental impacts.

Core Principles of Reflexive Modernization

Reflexive modernization centers on the self-critical examination of modernity's risks and uncertainties, emphasizing the transformation of institutions through continuous feedback and adaptation. Core principles include the deconstruction of traditional social structures, increased transparency, and the democratization of knowledge to manage complex technological and ecological challenges. Unlike industrial modernization's focus on technological progress and economic growth, reflexive modernization prioritizes sustainability, accountability, and the co-evolution of society and technology.

Historical Contexts: Industrial vs Reflexive Modernization

Industrial modernization emerged during the 18th and 19th centuries with the rise of mechanized production, urbanization, and the establishment of factory systems, fundamentally transforming economic and social structures. Reflexive modernization, developing in the late 20th century, emphasizes self-critical awareness of modernization's risks, such as environmental degradation and social inequalities, leading to institutional reforms and new governance models. These historical contexts highlight a shift from external, production-driven changes in industrial modernization to internal, risk-focused adaptations in reflexive modernization.

Key Drivers of Industrial Modernization

Industrial modernization is primarily driven by advancements in technology, increased automation, and the integration of digital systems such as IoT and AI to enhance productivity and operational efficiency. Key factors include the adoption of sustainable energy solutions, innovation in manufacturing processes, and the shift towards smart factories that enable real-time data analysis and adaptive control. Investment in workforce skills development and infrastructure modernization also plays a critical role in sustaining competitive advantage and fostering economic growth within industrial sectors.

Social Implications of Reflexive Modernization

Reflexive modernization emphasizes the self-confrontation of societies with the unintended consequences of industrial modernization, leading to heightened awareness of risks and uncertainties in social structures. It fosters critical public debates on issues like environmental degradation, technological hazards, and social inequality, thereby transforming traditional institutions and governance models. This process encourages inclusive participation and reflexivity, promoting adaptive social policies that address complex global challenges more effectively than conventional industrial modernization.

Technological Advancements in Both Paradigms

Industrial modernization emphasizes the mechanization and mass production driven by innovations like the steam engine and assembly lines, which transformed manufacturing efficiency. Reflexive modernization centers on integrating advanced technologies such as information systems, biotechnology, and renewable energy to address risks and uncertainties generated by earlier industrial changes. Both paradigms highlight technological advancements as key drivers but differ in scale and focus, with industrial modernization aiming at production expansion and reflexive modernization targeting adaptive, sustainable progress.

Risks and Opportunities in Modernization Processes

Industrial modernization emphasizes large-scale technological advancements and infrastructure upgrades, offering opportunities for increased productivity and economic growth but risking environmental degradation and social displacement. Reflexive modernization involves critical self-assessment of modernization impacts, promoting sustainable development and adaptive governance while facing challenges in managing complex uncertainties and conflicting stakeholder interests. Balancing these approaches requires integrating innovation with reflexivity to mitigate risks and maximize resilient, inclusive modernization outcomes.

Case Studies: Comparing Industrial and Reflexive Models

Case studies comparing industrial and reflexive modernization models reveal distinct approaches to technological innovation and social change. Industrial modernization emphasizes mass production, standardized processes, and economic growth driven by mechanization, as seen in the 19th and early 20th centuries' manufacturing sectors. Reflexive modernization, exemplified by post-industrial societies, focuses on adaptive technologies, environmental sustainability, and self-critical institutional reforms that respond to complex social challenges and uncertainties.

Future Trajectories and Policy Implications

Industrial modernization emphasizes technological innovation, infrastructure development, and economic growth as key drivers for future trajectories, promoting policies that support industrial investment and market expansion. Reflexive modernization focuses on societal self-awareness and critical evaluation of the consequences of modernization, encouraging policies that integrate environmental sustainability, risk management, and ethical considerations. Policy implications suggest balancing industrial growth with reflexive strategies to ensure resilient, adaptive, and socially responsible development pathways.

Industrial modernization Infographic

libterm.com

libterm.com