A strong baseline is essential for measuring your project's progress and ensuring consistent performance over time. It provides a clear reference point that helps identify deviations and optimize future strategies. Explore the rest of the article to learn how establishing an effective baseline can transform your results.

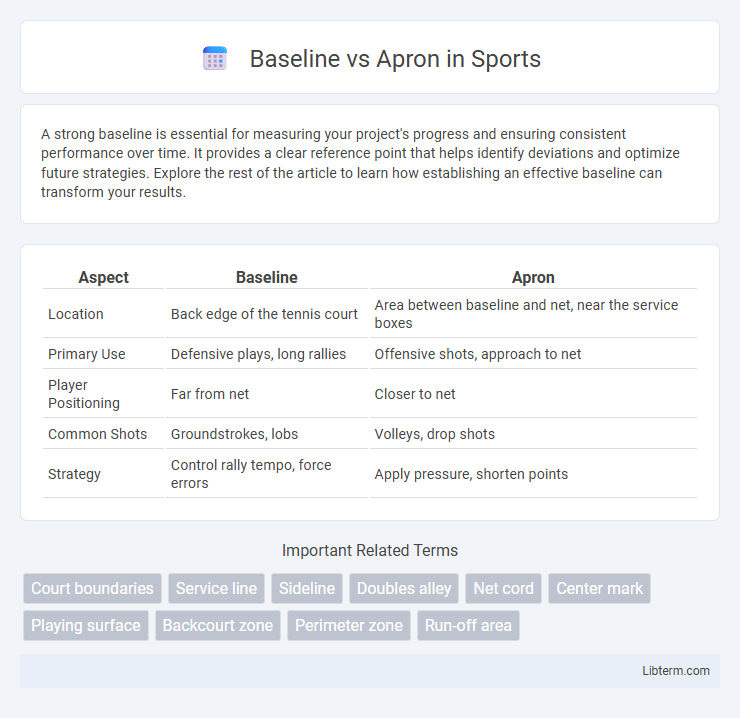

Table of Comparison

| Aspect | Baseline | Apron |

|---|---|---|

| Location | Back edge of the tennis court | Area between baseline and net, near the service boxes |

| Primary Use | Defensive plays, long rallies | Offensive shots, approach to net |

| Player Positioning | Far from net | Closer to net |

| Common Shots | Groundstrokes, lobs | Volleys, drop shots |

| Strategy | Control rally tempo, force errors | Apply pressure, shorten points |

Understanding Baseline and Apron: Definitions

Baseline refers to a fixed reference line used in field surveys and mapping to ensure accurate measurements and alignment of structures, serving as a fundamental starting point. Apron in construction denotes a paved or concrete area, typically surrounding an aircraft parking or loading zone, designed to provide a stable surface for vehicles and equipment. Understanding the distinct roles of baseline as a measurement anchor and apron as a physical surface is essential for precise engineering and airport design applications.

Key Functional Differences Between Baseline and Apron

Baseline refers to the standard measurement or reference point used in project management and design to track progress and performance, while Apron in aviation is the designated area where aircraft are parked, loaded, unloaded, refueled, or boarded. The key functional difference lies in their application: Baseline serves as a control tool for monitoring project scope and schedule changes, whereas Apron functions as a critical infrastructure component supporting airport ground operations and aircraft servicing. Baseline emphasizes data consistency and project alignment, whereas Apron ensures operational efficiency and aircraft turnaround on the airfield.

Structural Importance of Baseline in Construction

The baseline in construction serves as a critical reference point that ensures accurate alignment and measurement across the entire project site, forming the foundation for structural integrity. Unlike the apron, which primarily protects and finishes the base of structures such as sidewalks or runways, the baseline dictates precise placement of walls, columns, and other key elements, thereby preventing cumulative errors. Its structural importance lies in maintaining consistency and stability throughout the construction process, directly influencing the durability and safety of the finished building.

Apron: Purpose and Applications in Building Design

The apron in building design serves as a protective element placed at the base of exterior walls, preventing soil erosion and water damage near the foundation. It is commonly made from durable materials such as concrete or asphalt, providing a sturdy barrier against weather elements and heavy foot traffic. Aprons enhance structural longevity by diverting moisture away from the foundation and improving site drainage around buildings.

Baseline vs Apron: Comparative Advantages

Baseline provides a clear reference line critical for precise measurements in design and construction, ensuring consistent alignment across projects. Apron offers a protective or decorative element typically used in architecture and clothing, enhancing durability and aesthetics. Comparing baseline vs apron reveals that baseline is essential for measurement accuracy, while apron delivers functional protection and style.

Materials Used for Baseline and Apron

Baselines are typically made from durable materials such as polypropylene or polyester to withstand frequent contact and environmental exposure. Aprons are often constructed from waterproof and abrasion-resistant fabrics like PVC-coated polyester or rubberized materials to provide protection against spills and chemicals. Choosing the right material for baselines ensures accurate markings and long-term visibility, while apron materials prioritize user safety and durability.

Installation Process: Baseline Versus Apron

The installation process for a baseline involves setting a reference line or level to ensure accurate alignment and measurements, typically used in surveying or construction layout. An apron installation requires preparing a smooth, sloped surface at the edge of a pavement or doorway to facilitate drainage and prevent water accumulation. Both methods demand precise leveling tools, but baseline establishment prioritizes measurement accuracy while apron installation emphasizes surface grading and water management.

Impact on Durability and Maintenance

Baseline materials typically offer moderate durability but require frequent maintenance to address wear and environmental exposure. Apron construction utilizes reinforced surfaces that enhance resistance to abrasion, significantly extending lifespan while reducing maintenance frequency. The increased structural integrity of apron designs minimizes repair costs by protecting critical areas from damage caused by heavy use and weathering.

Cost Considerations: Baseline Compared to Apron

Baseline surfaces typically incur lower initial construction costs compared to apron installations due to simpler design and material requirements. Aprons demand higher investment due to reinforced concrete usage and enhanced durability features designed for heavy load-bearing and erosion resistance. Long-term maintenance expenses are generally reduced with aprons, offsetting their higher upfront costs through increased lifespan and lowered repair frequency.

Choosing Between Baseline and Apron for Your Project

Choosing between a baseline and an apron depends on the specific needs of your project's foundation and surface support. A baseline serves as a fundamental reference line for measurements and alignment in construction, essential for maintaining accuracy and consistency. An apron, typically a flat slab or paved area adjacent to structures, provides additional protection against erosion and supports heavy equipment, making it ideal for projects requiring reinforced surface stability.

Baseline Infographic

libterm.com

libterm.com