Oil glaze enhances the richness and depth of paintings by applying thin, translucent layers of oil-based paint over dried layers, creating luminous color effects and smooth texture transitions. This technique maximizes color vibrancy and adds a glossy finish that makes your artwork visually striking and professionally polished. Discover how mastering oil glaze can transform your paintings by reading the full article.

Table of Comparison

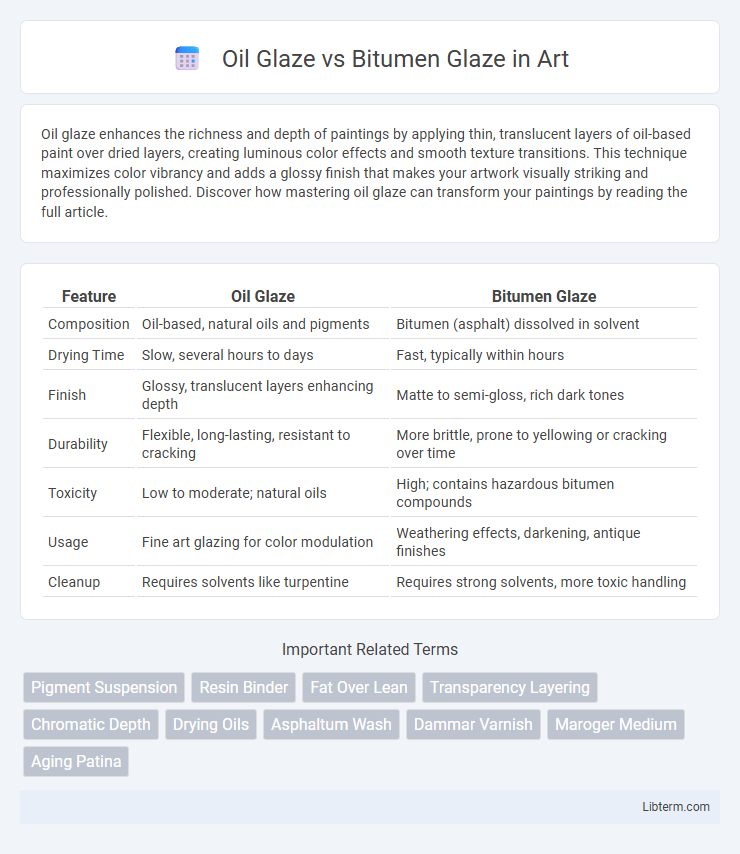

| Feature | Oil Glaze | Bitumen Glaze |

|---|---|---|

| Composition | Oil-based, natural oils and pigments | Bitumen (asphalt) dissolved in solvent |

| Drying Time | Slow, several hours to days | Fast, typically within hours |

| Finish | Glossy, translucent layers enhancing depth | Matte to semi-gloss, rich dark tones |

| Durability | Flexible, long-lasting, resistant to cracking | More brittle, prone to yellowing or cracking over time |

| Toxicity | Low to moderate; natural oils | High; contains hazardous bitumen compounds |

| Usage | Fine art glazing for color modulation | Weathering effects, darkening, antique finishes |

| Cleanup | Requires solvents like turpentine | Requires strong solvents, more toxic handling |

Introduction to Glazing in Art and Construction

Oil glaze and bitumen glaze serve distinct functions in art and construction, enhancing surface texture and protection through transparent layers. Oil glaze, typically made from linseed oil mixed with pigments, creates a smooth, glossy finish that enriches color depth in paintings and woodwork. Bitumen glaze, derived from natural asphalt, offers a dark, matte coating used for waterproofing and weatherproofing surfaces in building materials.

Defining Oil Glaze: Composition and Uses

Oil glaze consists of natural oils such as linseed or tung oil blended with solvent and pigments to create a translucent finish that enhances wood grain and depth. Common in woodworking and fine furniture restoration, oil glaze penetrates surfaces, providing protection while enriching color and texture. Unlike bitumen glaze, which is primarily used for its waterproofing and darkening properties, oil glaze emphasizes aesthetic enhancement and surface durability.

Understanding Bitumen Glaze: Properties and Applications

Bitumen glaze is a viscous, black, waterproof coating derived from bitumen, widely used for protecting surfaces from moisture and corrosion due to its excellent adhesive and insulating properties. Its high resistance to chemicals and weathering makes it ideal for roofing, road construction, and metal protection applications. Compared to oil glaze, bitumen glaze offers superior durability and water resistance, making it a preferred choice in heavy-duty industrial environments.

Key Differences Between Oil Glaze and Bitumen Glaze

Oil glaze is a transparent, slow-drying finish made from natural oils, providing a smooth, glossy surface ideal for enhancing wood grain, while bitumen glaze is a dark, thick, tar-based coating primarily used for waterproofing and protecting surfaces from corrosion. Oil glaze offers flexibility and ease of reapplication, making it suitable for decorative and protective interior wood finishes, whereas bitumen glaze is more durable and resistant to harsh environmental conditions, commonly applied on metal and concrete structures. The key differences lie in their composition, drying times, finish appearance, and typical usage scenarios, with oil glaze focusing on aesthetics and bitumen glaze emphasizing protection and durability.

Aesthetic Outcomes: Color, Finish, and Texture

Oil glaze produces a warm, amber-toned finish that enhances wood grain with a smooth, satin sheen, creating a natural and rich aesthetic. Bitumen glaze offers a darker, more opaque appearance with matte to semi-gloss finishes, imparting a rustic or aged look characterized by deeper textures and subtle variations. Both glazes influence color depth and surface texture distinctly, with oil glaze emphasizing clarity and warmth, while bitumen glaze favors depth and vintage character.

Durability and Longevity: Oil Glaze vs Bitumen Glaze

Oil glaze offers moderate durability with a natural finish that enhances wood grain but requires regular maintenance to prevent wear and fading. Bitumen glaze provides superior longevity by forming a robust, waterproof barrier resistant to UV rays, moisture, and harsh weather conditions. The choice between the two depends on the desired lifespan and maintenance frequency, with bitumen glaze favored for long-term protection in outdoor applications.

Application Techniques for Both Glaze Types

Oil glaze application involves brushing a thin, even coat over painted or wooden surfaces to enhance depth and richness, often requiring multiple layers with drying time in between for optimal results. Bitumen glaze, commonly used on masonry and metal surfaces, is applied using a brush or spray method, emphasizing quick, uniform coverage to create a protective, waterproof barrier. Both techniques demand surface preparation such as cleaning and priming to ensure adhesion and durability of the glaze finish.

Environmental and Safety Considerations

Oil glaze typically contains volatile organic compounds (VOCs) that contribute to air pollution and pose health risks such as skin irritation and respiratory issues during application. Bitumen glaze, derived from petroleum, is less volatile but can release harmful polycyclic aromatic hydrocarbons (PAHs), which are carcinogenic and require careful handling and disposal to avoid environmental contamination. Choosing low-VOC or water-based alternatives can mitigate environmental impact and enhance worker safety by reducing toxic emissions and flammability concerns.

Cost Effectiveness: Which Glaze is More Affordable?

Oil glaze typically offers a more affordable option due to lower material costs and easier application methods compared to bitumen glaze, which often requires specialized handling and longer curing times that increase overall expenses. Bitumen glaze, while providing superior waterproofing and durability, tends to be costlier because of its complex formulation and labor-intensive process. For budget-conscious projects, oil glaze presents a cost-effective solution without significantly compromising on protective qualities.

Choosing the Right Glaze for Your Project

Choosing the right glaze depends on the project's surface and desired finish; oil glaze offers a durable, glossy coat ideal for wood and metal, enhancing natural textures while providing excellent protection against moisture. Bitumen glaze is best suited for waterproofing and sealing in construction or roofing applications due to its strong adhesive qualities and resistance to harsh weather conditions. Evaluating the substrate type and environmental exposure ensures the optimal selection between oil and bitumen glaze for lasting performance.

Oil Glaze Infographic

libterm.com

libterm.com