Screen printing offers vibrant, long-lasting designs ideal for apparel, signage, and posters, using a mesh stencil to apply ink precisely. This technique excels at producing large quantities quickly while maintaining high quality and color consistency. Explore the full article to learn how screen printing can transform Your creative projects with professional results.

Table of Comparison

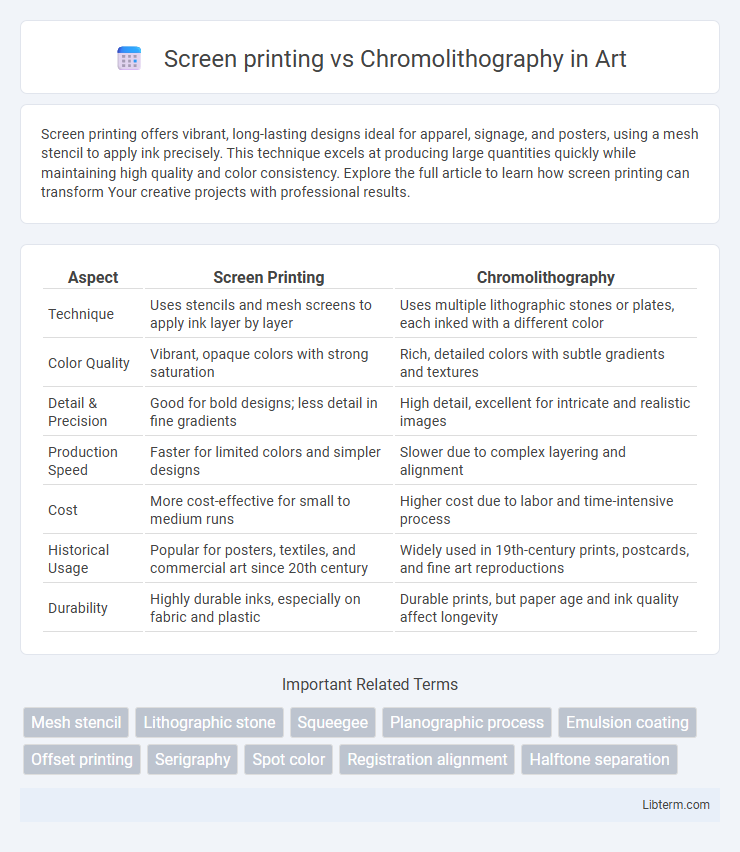

| Aspect | Screen Printing | Chromolithography |

|---|---|---|

| Technique | Uses stencils and mesh screens to apply ink layer by layer | Uses multiple lithographic stones or plates, each inked with a different color |

| Color Quality | Vibrant, opaque colors with strong saturation | Rich, detailed colors with subtle gradients and textures |

| Detail & Precision | Good for bold designs; less detail in fine gradients | High detail, excellent for intricate and realistic images |

| Production Speed | Faster for limited colors and simpler designs | Slower due to complex layering and alignment |

| Cost | More cost-effective for small to medium runs | Higher cost due to labor and time-intensive process |

| Historical Usage | Popular for posters, textiles, and commercial art since 20th century | Widely used in 19th-century prints, postcards, and fine art reproductions |

| Durability | Highly durable inks, especially on fabric and plastic | Durable prints, but paper age and ink quality affect longevity |

Introduction to Screen Printing and Chromolithography

Screen printing is a versatile printing technique where ink is forced through a stencil on a mesh screen to create bold, vibrant designs, ideal for textiles, posters, and signage. Chromolithography, developed in the 19th century, is a method of multi-color printing using separate lithographic stones for each color, renowned for producing richly detailed and colorful prints. Both methods have distinct applications: screen printing excels in durability and large-scale production, while chromolithography is prized for fine art reproductions and intricate color gradients.

Historical Overview of Each Printing Method

Screen printing, originating in ancient China around 960 AD, gained widespread popularity in the early 20th century for its versatility in printing on various materials such as fabric, glass, and metal. Chromolithography, developed in the 19th century by Alois Senefelder, revolutionized color printing by using multiple lithographic stones for each color, making it the dominant method for vibrant, multi-colored prints during the Victorian era. Both methods significantly impacted the commercial and artistic printing industries, with screen printing evolving into a staple for mass production and chromolithography setting new standards for detailed, color-accurate reproductions.

Core Principles and Techniques

Screen printing employs a mesh stencil to apply ink directly onto a substrate, creating bold, vibrant designs with precise color layering through multiple passes. Chromolithography relies on chemically treating stone or metal plates to produce detailed, multi-colored images by sequentially printing each color with a separate lithographic plate. Both techniques emphasize color accuracy and reproduction fidelity but differ significantly in their processes: screen printing uses physical ink deposition while chromolithography depends on ink transfer through treated surfaces.

Materials and Equipment Used

Screen printing employs a mesh screen, squeegee, and specialized inks that adhere to a variety of materials like textiles, paper, and plastics, allowing for versatility and vibrant color application. Chromolithography relies on multiple stone or metal plates, each etched for a specific color layer, requiring precise alignment and craftsmanship to produce detailed, multicolor prints primarily on paper. The durability of screen printing hardware and the complexity of chromolithographic presses significantly influence production speed and artwork complexity.

Image Quality and Color Reproduction

Screen printing excels in vibrant color saturation and durability, producing bold, solid areas of ink ideal for graphic designs with fewer colors. Chromolithography offers superior color gradation and fine detail through layered lithographic stones, ensuring high-resolution images with smooth transitions between hues. While screen printing emphasizes vividness and texture, chromolithography provides exceptional color fidelity and delicate shading for intricate, photorealistic prints.

Versatility and Suitable Applications

Screen printing offers exceptional versatility by allowing printing on a wide range of materials including textiles, glass, ceramics, and metals, making it ideal for custom apparel, posters, and industrial products. Chromolithography, known for its high-quality and vibrant color reproduction, is best suited for fine art prints, vintage posters, and decorative prints where detailed color gradation is essential. Screen printing excels in durability and large-scale production, whereas chromolithography is preferred for limited edition prints demanding rich color depth and historical authenticity.

Production Speed and Efficiency

Screen printing offers faster production speeds for small to medium runs due to its direct stencil process and quick drying inks, making it highly efficient for custom or limited-edition prints. Chromolithography, requiring multiple plates and color layers, involves a lengthier setup and printing time, resulting in slower output but high-quality, detailed prints ideal for large-scale productions. Efficiency in screen printing is maximized through automation and simplified workflow, whereas chromolithography demands meticulous alignment and longer preparation, impacting overall production speed.

Cost Considerations and Accessibility

Screen printing offers lower setup costs and is more accessible for small runs or custom projects, making it ideal for startups and small businesses. Chromolithography involves higher initial expenses due to complex color separation and plate preparation but offers excellent image quality for large-scale, high-volume print jobs. While screen printing provides flexibility and affordability, chromolithography excels in producing detailed, vibrant prints at scale, impacting overall cost and accessibility depending on project size and budget.

Environmental Impact and Sustainability

Screen printing generates significant waste through the use of inks, stencils, and chemicals, often leading to water and soil contamination if not properly managed. Chromolithography, relying on multiple layers of colored inks and heavy use of solvents, contributes to air pollution and higher energy consumption throughout its complex process. Sustainable practices in screen printing include water-based inks and recyclable materials, while chromolithography demands advanced waste treatment and solvent recovery systems to minimize environmental harm.

Choosing the Right Method for Your Project

Screen printing offers vibrant colors and durability, making it ideal for apparel and signage requiring long-lasting visuals. Chromolithography excels in producing finely detailed, multi-colored prints perfect for art reproductions and high-quality posters. Evaluate project needs such as color complexity, budget, and print volume to select the most efficient and cost-effective method.

Screen printing Infographic

libterm.com

libterm.com