Carving transforms raw materials like wood, stone, or ice into intricate shapes through precise cutting and shaping techniques. Mastering carving enhances your artistic expression and craftsmanship, allowing you to create detailed sculptures, decorations, and functional objects. Explore the rest of the article to discover essential carving tools, techniques, and tips to refine your skills.

Table of Comparison

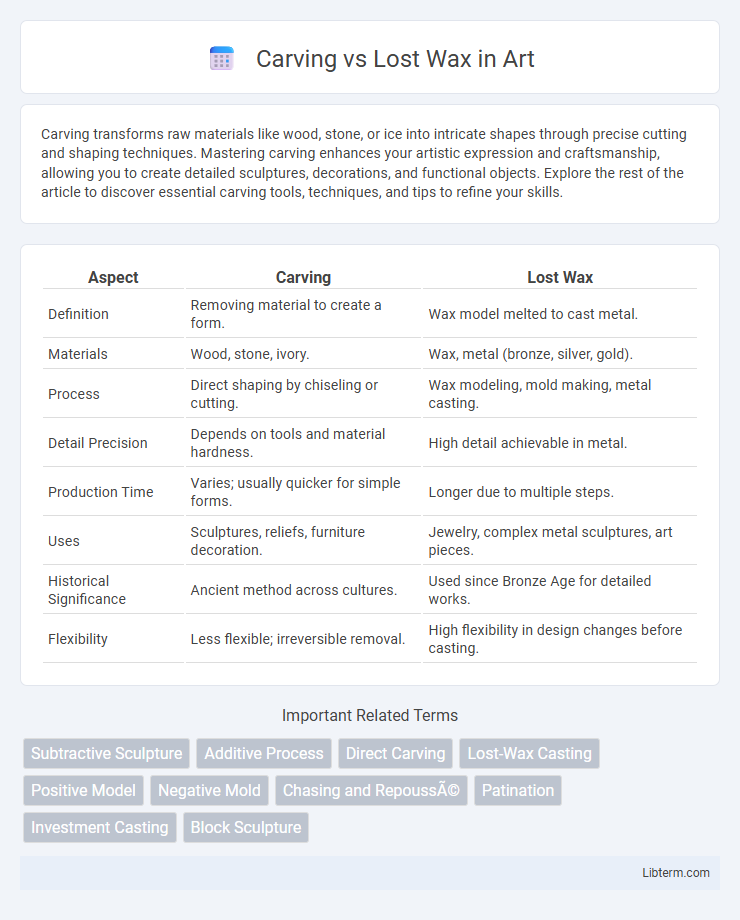

| Aspect | Carving | Lost Wax |

|---|---|---|

| Definition | Removing material to create a form. | Wax model melted to cast metal. |

| Materials | Wood, stone, ivory. | Wax, metal (bronze, silver, gold). |

| Process | Direct shaping by chiseling or cutting. | Wax modeling, mold making, metal casting. |

| Detail Precision | Depends on tools and material hardness. | High detail achievable in metal. |

| Production Time | Varies; usually quicker for simple forms. | Longer due to multiple steps. |

| Uses | Sculptures, reliefs, furniture decoration. | Jewelry, complex metal sculptures, art pieces. |

| Historical Significance | Ancient method across cultures. | Used since Bronze Age for detailed works. |

| Flexibility | Less flexible; irreversible removal. | High flexibility in design changes before casting. |

Introduction to Carving and Lost Wax Techniques

Carving is a traditional sculpting method involving the removal of material from wood, stone, or other solid mediums to create detailed forms, prioritizing precision and manual skill. Lost wax casting, also known as investment casting, uses a wax model encased in a heat-resistant mold that melts away during firing, leaving a cavity for molten metal to fill, enabling intricate metalwork replication. Both techniques offer unique advantages in artistic and industrial applications, with carving excelling in direct manipulation and lost wax allowing for complex metal reproductions.

Historical Background of Carving and Lost Wax

Carving as a technique dates back to prehistoric times, with evidence found in ancient civilizations such as Mesopotamia and Egypt, where artisans sculpted wood, stone, and bone for both functional and decorative purposes. Lost Wax casting, also known as cire-perdue, originated around 3500 BCE in Mesopotamia and later flourished in regions like the Indus Valley and Africa, enabling detailed metalwork through a process involving wax models coated in clay or plaster molds. Both methods have evolved through millennia, preserving cultural heritage and advancing artistic expression across diverse societies.

Overview of Carving: Methods and Materials

Carving involves sculpting materials such as wood, stone, or ice by removing portions to create a desired shape, relying on tools like chisels, knives, and mallets for precision. This subtractive method demands careful planning and skill to achieve intricate details and smooth finishes. Common materials include hardwoods like mahogany, soft stones such as alabaster, and synthetic substances, each influencing the carving technique and final texture.

Overview of Lost Wax: Process and Materials

The lost wax process involves creating a detailed wax model that is encased in a refractory mold material, often a mixture of silica, plaster, or ceramic. Once the mold hardens, the wax is melted away, leaving a precise cavity for molten metal casting, commonly bronze, gold, or silver. This technique enables intricate designs and fine surface details that are challenging to achieve with direct carving methods.

Key Differences Between Carving and Lost Wax

Carving involves shaping a solid material, such as wood or stone, by removing parts to create a final form, while lost wax is a casting process where a wax model is used to produce intricate metal objects through mold making. Carving allows for direct manipulation and immediate adjustments, whereas lost wax offers high precision in reproducing complex details and fine textures. The choice depends on the desired material, detail level, and production scale, with carving favored for one-of-a-kind pieces and lost wax suited for detailed metalwork and mass duplication.

Advantages of Carving in Art and Jewelry

Carving offers unparalleled control over the artistic process, enabling artists to directly shape and refine materials for intricate and unique jewelry designs. This hands-on technique allows for immediate adjustments and a tactile connection with the medium, enhancing precision and creativity. Unlike the Lost Wax method, carving reduces dependency on molds and casting, minimizing production time and material waste.

Benefits of Lost Wax Casting in Modern Craft

Lost wax casting offers unparalleled precision and detail, allowing modern artisans to create intricate designs that are difficult to achieve through traditional carving. The process supports complex geometries and thin-walled structures, enhancing artistic freedom and material efficiency. Its adaptability to various metals and alloys makes it a preferred technique for producing high-quality, durable pieces in contemporary jewelry and sculpture.

Common Applications of Carving vs Lost Wax

Carving is commonly used for direct shaping of materials such as wood, stone, and soap, ideal for crafting sculptures, architectural details, and custom furniture. Lost wax casting excels in producing intricate metal objects like jewelry, statues, and industrial components, where precision and complex geometries are required. Both techniques serve artistic and manufacturing purposes but differ in material application and detail fidelity.

Durability and Precision: Carving vs Lost Wax

Carving techniques provide high durability by using sturdy materials like wood or stone but may lack the fine precision achieved through the lost wax method. Lost wax casting offers exceptional precision and intricate detail reproduction due to its ability to capture minute features from wax models. The combination of lost wax casting's accuracy and the lasting durability of metals typically surpasses traditional carving in creating long-lasting, finely detailed objects.

Choosing the Right Technique: Factors to Consider

Choosing the right technique between carving and lost wax depends on the desired level of detail, production volume, and material used. Carving is ideal for larger, solid pieces with less intricate details, offering direct control over the shape, while lost wax casting excels in creating complex, highly detailed items with smooth finishes. Material compatibility, cost efficiency, and project timeline also influence the choice, with lost wax providing superior precision for fine metals like gold and silver.

Carving Infographic

libterm.com

libterm.com