Priming enhances your brain's ability to respond faster and more accurately by activating related memories or concepts before receiving new information. This psychological technique improves learning, decision-making, and behavior by setting mental cues that shape perception and reactions. Explore the rest of this article to discover how priming can boost your cognitive performance and everyday interactions.

Table of Comparison

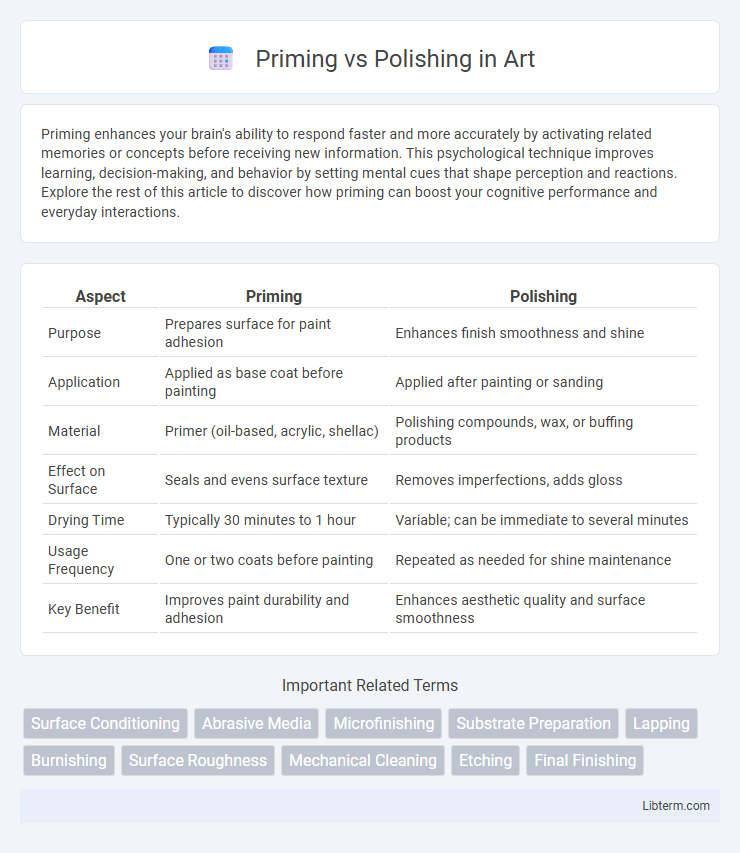

| Aspect | Priming | Polishing |

|---|---|---|

| Purpose | Prepares surface for paint adhesion | Enhances finish smoothness and shine |

| Application | Applied as base coat before painting | Applied after painting or sanding |

| Material | Primer (oil-based, acrylic, shellac) | Polishing compounds, wax, or buffing products |

| Effect on Surface | Seals and evens surface texture | Removes imperfections, adds gloss |

| Drying Time | Typically 30 minutes to 1 hour | Variable; can be immediate to several minutes |

| Usage Frequency | One or two coats before painting | Repeated as needed for shine maintenance |

| Key Benefit | Improves paint durability and adhesion | Enhances aesthetic quality and surface smoothness |

Introduction to Priming and Polishing

Priming involves applying a preparatory coating to surfaces to enhance adhesion, prevent corrosion, and ensure a uniform finish in painting processes. Polishing is the process of creating a smooth and shiny surface by abrasive rubbing or chemical treatment to improve appearance and texture. Both techniques are essential in surface preparation and finishing, with priming providing a base layer and polishing refining the final look.

Defining Priming: Purpose and Process

Priming is a preparatory process in painting that creates a uniform surface by applying a base coat to raw materials like wood, metal, or drywall. Its primary purpose is to enhance adhesion, prevent stains, and seal porous surfaces, ensuring better durability and finish quality. The process involves applying specific primer formulations tailored to substrate characteristics that improve topcoat bonding and protect against corrosion or moisture.

Understanding Polishing: Techniques and Goals

Polishing involves refining a surface by removing fine imperfections to achieve a smooth, glossy finish, often using abrasive compounds or buffing tools. The goal of polishing is to enhance the aesthetic appeal and durability of materials like metals, plastics, or wood, while preparing them for final coatings or display. Techniques vary from wet sanding to machine buffing, each tailored to the material's properties and desired gloss level.

Key Differences Between Priming and Polishing

Priming involves applying a preparatory coating to surfaces to enhance paint adhesion and increase durability, while polishing focuses on smoothing and shining surfaces by removing imperfections like scratches or oxidation. Primers create a uniform base, sealing porous materials and improving paint coverage, whereas polishing refines the existing finish to restore gloss and clarity. The primary difference lies in priming being a base-preparation step, and polishing serving as a restorative or finishing process to enhance surface aesthetics.

Materials and Tools Required for Each Step

Priming requires materials like high-quality primer suited for the surface type, brushes, rollers, or spray guns designed for even application. Polishing involves tools such as polishing pads, buffing machines, and abrasives including polishing compounds or waxes tailored for the specific material being treated. Both steps demand proper preparation tools and surface cleaners to ensure optimal adhesion and finish quality.

Surface Preparation: Priming vs Polishing

Surface preparation techniques such as priming and polishing serve distinct purposes in enhancing material performance and appearance. Priming involves applying a base coat to promote adhesion, protect the substrate, and create a uniform surface for subsequent layers, typically used in painting or coating processes. Polishing, on the other hand, is a mechanical or chemical method to smooth and refine surfaces by removing imperfections, increasing gloss, and improving tactile quality, often employed in metals, glass, and automotive finishes.

Impact on Material Durability and Finish

Priming creates a protective base layer that enhances adhesion and prevents corrosion, significantly increasing material durability. Polishing smooths the surface, improving aesthetic finish and reducing microscopic imperfections that can lead to wear or damage. Combining priming with polishing results in a durable, visually appealing surface resistant to environmental stress and mechanical abrasion.

When to Prime and When to Polish

Priming is essential when surfaces show stains, discoloration, or damage, providing a uniform base that improves paint adhesion and durability. Polishing is ideal for finished surfaces that require enhanced shine, scratch removal, and smoothness without altering the paint layer. Use priming before painting new or bare surfaces and polishing when maintaining or restoring gloss on existing paint.

Common Mistakes to Avoid

Common mistakes in priming include applying primer on a dirty or oily surface, which prevents proper adhesion and leads to peeling. In polishing, using abrasive compounds on delicate finishes can cause scratches or swirl marks, diminishing the paint's gloss. Overlooking compatibility between primer, paint, and polish often results in uneven textures and reduced durability.

Final Thoughts: Choosing the Right Method

Selecting between priming and polishing depends on the surface condition and desired finish quality; priming offers better adhesion and durability for rough or porous materials, while polishing enhances smoothness and shine on already finished surfaces. Consider the project's long-term exposure to elements, as primed surfaces often provide superior protection against wear and corrosion. Opting for the right method ensures optimal results in terms of aesthetics, longevity, and maintenance requirements.

Priming Infographic

libterm.com

libterm.com