Shaping is a behavioral technique used to gradually guide actions toward a desired outcome through successive approximations. This method is essential in training, learning, and personal development as it breaks complex behaviors into manageable steps. Discover how mastering shaping can transform your approach to achieving goals by reading the full article.

Table of Comparison

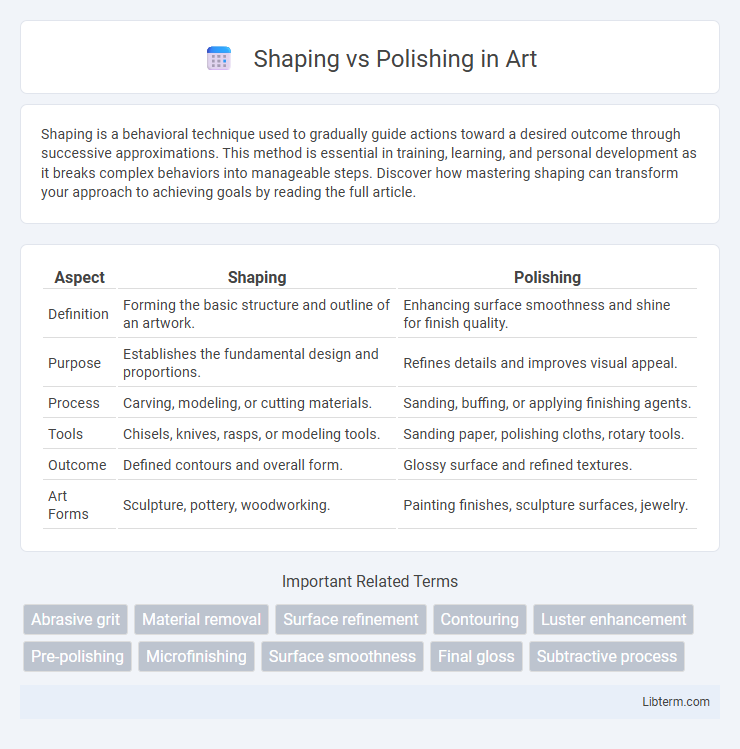

| Aspect | Shaping | Polishing |

|---|---|---|

| Definition | Forming the basic structure and outline of an artwork. | Enhancing surface smoothness and shine for finish quality. |

| Purpose | Establishes the fundamental design and proportions. | Refines details and improves visual appeal. |

| Process | Carving, modeling, or cutting materials. | Sanding, buffing, or applying finishing agents. |

| Tools | Chisels, knives, rasps, or modeling tools. | Sanding paper, polishing cloths, rotary tools. |

| Outcome | Defined contours and overall form. | Glossy surface and refined textures. |

| Art Forms | Sculpture, pottery, woodworking. | Painting finishes, sculpture surfaces, jewelry. |

Introduction to Shaping and Polishing

Shaping refers to the initial process of refining a material or surface to achieve a desired form, often involving cutting, grinding, or carving techniques. Polishing follows shaping by enhancing the surface finish through abrasion, producing a smooth, reflective, and aesthetically pleasing result. Both processes are essential in manufacturing, woodworking, and metalworking to create precise and high-quality products.

Defining Shaping in Material Processing

Defining shaping in material processing involves transforming raw materials into specific forms or geometries through mechanical, thermal, or chemical methods such as casting, forging, extrusion, or molding. Shaping aims to create the initial structure and dimensions required for further refinement, distinguishing it from polishing, which enhances surface smoothness and appearance. The efficiency of shaping directly impacts material properties and production costs by determining the accuracy and feasibility of subsequent processes.

What is Polishing?

Polishing is a finishing process that enhances the surface smoothness and shine of materials such as metal, wood, or plastic by removing fine scratches and imperfections. This technique improves aesthetic appeal and prevents corrosion or wear by creating a reflective, glossy surface. Polishing often involves abrasive compounds and specialized tools like buffing wheels or polishing pads tailored to the specific material.

Key Differences Between Shaping and Polishing

Shaping involves removing excess material to create the desired form or contour, typically using abrasives or cutting tools, while polishing focuses on smoothing surfaces to enhance shine and reduce imperfections using finer abrasives or polishing compounds. The key difference lies in their objectives: shaping alters form and dimensions, whereas polishing improves surface texture and appearance. Shaping is a coarse process often done early in manufacturing, whereas polishing is a finishing step aimed at achieving a refined surface finish.

Tools and Techniques for Shaping

Shaping involves the use of specialized tools such as shaping knives, carving chisels, and rasps designed to remove material and create rough contours or forms in wood, metal, or other materials. Techniques for shaping include controlled cutting strokes, precise pressure application, and gradual material removal to ensure accurate dimensions and desired shapes. Mastery of these tools and techniques allows craftsmen to prepare a structured foundation that can be refined further through polishing processes.

Polishing Methods and Materials

Polishing methods often involve abrasive materials such as diamond paste, aluminum oxide, or silicon carbide combined with polishing wheels, cloths, or pads to achieve a smooth, reflective surface. Mechanical polishing techniques utilize rotary tools or vibratory tumblers, while chemical-mechanical polishing (CMP) applies both chemical etchants and abrasives for precise surface finishing. Common materials polished include metals, gemstones, ceramics, and optical lenses, with specific abrasives selected based on hardness and desired finish quality.

Applications of Shaping vs. Polishing

Shaping is primarily used for removing substantial material to form or alter the basic geometry of a workpiece in applications such as metal fabrication, woodworking, and stone carving. Polishing, on the other hand, is applied to improve surface finish, enhance aesthetics, and reduce friction in products like automotive parts, optical lenses, and electronic components. Industries leverage shaping for structural precision and polishing for surface refinement and performance enhancement.

Benefits and Drawbacks of Shaping

Shaping strategically modifies the structure of a product or service to better align with market demands, offering benefits such as enhanced user experience and increased competitive advantage. However, shaping can involve higher initial costs and the risk of misaligned changes if customer insights are inaccurate. Its impact on long-term innovation requires careful balancing between flexibility and maintaining core functionalities.

Advantages and Disadvantages of Polishing

Polishing enhances surface smoothness and brightness, improving aesthetic appeal and reducing friction, which extends the lifespan of materials. However, it can remove microscopic layers, potentially weakening delicate surfaces and increasing susceptibility to damage over time. The process often requires more time and specialized equipment compared to shaping, making it less efficient for rapid production needs.

Choosing the Right Process: Shaping or Polishing?

Choosing the right process between shaping and polishing depends on the desired outcome and material type. Shaping removes excess material to create the basic form, while polishing enhances surface smoothness and shine. For initial material removal, shaping is essential, whereas polishing is best suited for final finishing to achieve a refined appearance.

Shaping Infographic

libterm.com

libterm.com