Plaster mold casting offers precise detail and smooth surface finishes, making it ideal for complex metal parts and prototypes. This technique uses a mixture of plaster combined with additives to create durable molds that can withstand high temperatures during metal pouring. Discover how plaster mold casting can enhance your manufacturing process and improve your product quality by reading the full article.

Table of Comparison

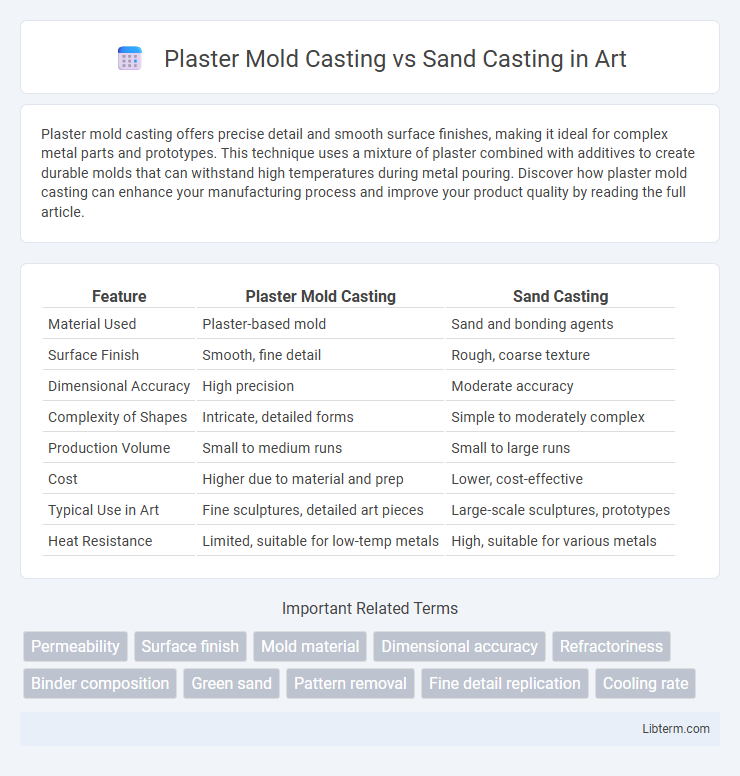

| Feature | Plaster Mold Casting | Sand Casting |

|---|---|---|

| Material Used | Plaster-based mold | Sand and bonding agents |

| Surface Finish | Smooth, fine detail | Rough, coarse texture |

| Dimensional Accuracy | High precision | Moderate accuracy |

| Complexity of Shapes | Intricate, detailed forms | Simple to moderately complex |

| Production Volume | Small to medium runs | Small to large runs |

| Cost | Higher due to material and prep | Lower, cost-effective |

| Typical Use in Art | Fine sculptures, detailed art pieces | Large-scale sculptures, prototypes |

| Heat Resistance | Limited, suitable for low-temp metals | High, suitable for various metals |

Introduction to Plaster Mold Casting and Sand Casting

Plaster mold casting utilizes a fine, high-strength plaster mixture to create detailed and smooth molds, ideal for producing complex and intricate metal parts with tight tolerances. Sand casting employs a sand-based mold, offering versatility and cost-effectiveness for larger, simpler components but with lower surface finish quality and dimensional accuracy. Both processes serve distinct manufacturing needs based on factors like mold material, casting complexity, and production volume.

Key Differences Between Plaster Mold and Sand Casting

Plaster mold casting utilizes a fine plaster-based mold, offering superior surface finish and dimensional accuracy compared to sand casting, which uses a coarser sand mold. Plaster molds are best suited for intricate, small to medium-sized parts requiring detailed features, while sand casting is more versatile, ideal for large castings with less precise tolerances. The cost and time for plaster mold casting are generally higher due to mold preparation, but it enables better reproduction of complex geometries and thinner walls than sand casting.

Materials Used in Plaster Mold Casting and Sand Casting

Plaster mold casting utilizes fine plaster of Paris mixed with water and additives, producing a smooth, high-resolution mold ideal for non-ferrous metals like aluminum, copper, and zinc alloys. Sand casting employs silica sand mixed with clay and water, creating a porous mold suitable for ferrous and non-ferrous metals including cast iron, steel, and bronze. The choice of mold material in plaster mold casting allows for intricate detail and fine surface finishes, whereas sand casting provides durability and reuse for larger, less detailed castings.

Step-by-Step Process: Plaster Mold Casting

Plaster mold casting involves creating a detailed mold by mixing plaster with water and pouring it around a pattern to form a shell, which hardens to capture fine surface details. After removing the pattern, the mold undergoes drying and baking to eliminate moisture before molten metal is poured into the cavity. This process offers superior dimensional accuracy and surface finish compared to sand casting, which uses compacted sand around a pattern and typically yields rougher textures.

Step-by-Step Process: Sand Casting

Sand casting involves creating a mold by compacting sand around a pattern, which is then removed to form a cavity. Molten metal is poured into this cavity and allowed to solidify before the sand mold is broken away to reveal the cast part. This process includes pattern making, molding, core making, pouring, cooling, and cleaning.

Surface Finish and Dimensional Accuracy Comparison

Plaster mold casting delivers superior surface finish with smooth, fine details due to the fine plaster material that minimizes grain size and reduces surface roughness compared to the coarse texture of sand used in sand casting. Dimensional accuracy in plaster mold casting is higher, typically within +-0.5%, as the rigid plaster mold resists distortion and allows precise replication of the pattern, whereas sand casting tends to have looser tolerances around +-2-3% due to sand grain shifting and mold deformation. This makes plaster mold casting ideal for complex, detailed components requiring tight dimensional control and enhanced aesthetic quality.

Cost Analysis: Plaster Mold Casting vs Sand Casting

Plaster mold casting typically incurs higher initial expenses due to the cost of plaster materials and the need for precise mold preparation, yet it offers fine surface finish and dimensional accuracy that potentially reduce post-processing costs. Sand casting is generally more cost-effective for low to medium production volumes, benefiting from reusable sand molds and lower material expenses, though it may require additional machining to achieve desired tolerances. Evaluating total production costs hinges on factors such as batch size, part complexity, and finishing requirements, with plaster mold casting preferred for intricate, small-to-medium runs and sand casting favored for larger, less precise components.

Applications and Industry Use Cases

Plaster mold casting excels in producing high-precision, complex parts with fine surface finishes, making it ideal for aerospace components, jewelry, and intricate automotive parts where dimensional accuracy is crucial. Sand casting is widely used in heavy industries such as construction, marine, and heavy machinery for large, durable metal parts due to its cost-effectiveness and versatility with various metals. Both processes serve distinct market needs, with plaster mold casting preferred for small-to-medium production runs requiring detail, whereas sand casting supports large-scale manufacturing of robust, structural components.

Advantages and Limitations of Each Casting Method

Plaster mold casting offers superior surface finish and high dimensional accuracy, making it ideal for intricate designs and thin-walled components, but it is limited by slower production rates and inability to handle large castings. Sand casting provides flexibility with large and complex geometries, cost-effectiveness for low-volume production, and rapid prototyping capabilities, though it results in rougher surface finish and less precise tolerances compared to plaster mold casting. Choosing between plaster mold and sand casting depends on the required precision, production volume, and component size.

Choosing the Right Casting Process for Your Project

Plaster mold casting offers superior surface finish and dimensional accuracy, making it ideal for intricate designs and small to medium-sized production runs. Sand casting is more cost-effective for large-scale projects and accommodates a wider range of metal alloys and part sizes with robust mechanical properties. Selecting the right casting process depends on factors like part complexity, production volume, budget constraints, and required material characteristics.

Plaster Mold Casting Infographic

libterm.com

libterm.com