Ball bearings reduce friction between moving parts by using smooth, spherical balls to maintain separation. These components enhance machine efficiency and longevity by minimizing wear and allowing precise motion. Explore the rest of the article to understand how ball bearings can improve your equipment's performance.

Table of Comparison

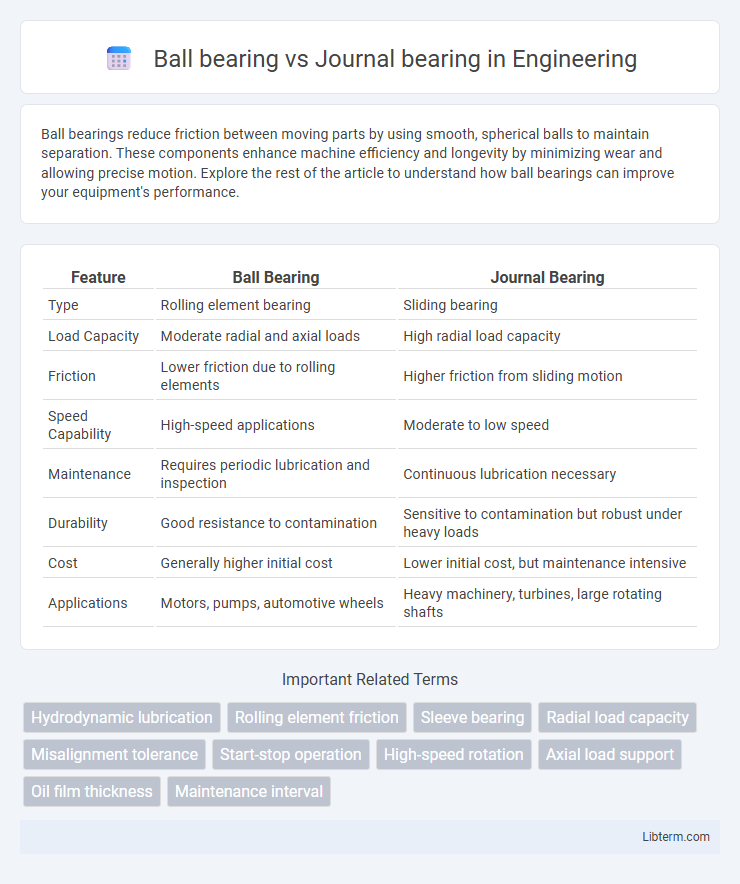

| Feature | Ball Bearing | Journal Bearing |

|---|---|---|

| Type | Rolling element bearing | Sliding bearing |

| Load Capacity | Moderate radial and axial loads | High radial load capacity |

| Friction | Lower friction due to rolling elements | Higher friction from sliding motion |

| Speed Capability | High-speed applications | Moderate to low speed |

| Maintenance | Requires periodic lubrication and inspection | Continuous lubrication necessary |

| Durability | Good resistance to contamination | Sensitive to contamination but robust under heavy loads |

| Cost | Generally higher initial cost | Lower initial cost, but maintenance intensive |

| Applications | Motors, pumps, automotive wheels | Heavy machinery, turbines, large rotating shafts |

Introduction to Ball Bearings and Journal Bearings

Ball bearings consist of rolling elements that reduce friction between rotating shafts and stationary components, offering high efficiency and the ability to support radial and axial loads. Journal bearings, also known as plain bearings, use a sliding motion with a lubricating film between the shaft and bearing surface, providing a simple design and excellent load-carrying capacity for heavy-duty applications. Both types are essential in mechanical systems, with ball bearings favored for precision and high-speed operations and journal bearings preferred for durability and shock absorption.

How Ball Bearings Work

Ball bearings work by using spherical balls to maintain the separation between bearing races, reducing friction and enabling smooth rotational motion. The balls rotate between an inner and outer ring, distributing loads evenly and minimizing surface contact area to decrease wear and heat generation. This design supports both radial and axial loads, enhancing machinery efficiency and longevity compared to journal bearings, which rely on sliding motion.

How Journal Bearings Function

Journal bearings function by supporting rotating shafts through a thin film of lubricant that separates the bearing surface from the shaft, reducing friction and wear. The load carried by the shaft creates pressure in the lubricant film, generating a hydrodynamic wedge that maintains rotor stability and minimizes metal-to-metal contact. This mechanism allows journal bearings to handle high loads and provide smooth, quiet operation, making them essential in applications like turbines, engines, and heavy machinery.

Key Differences Between Ball Bearings and Journal Bearings

Ball bearings utilize rolling elements to reduce friction between rotating shafts and stationary parts, enabling high-speed and low-load applications with precise motion control. Journal bearings rely on a thin film of lubricant to support radial loads by creating hydrodynamic pressure between the shaft and bearing surface, suitable for heavy-load and low-speed operations. Key differences include the mechanism of friction reduction, load capacity, speed limits, and typical applications, where ball bearings excel in precision and speed while journal bearings offer durability under heavy loads.

Performance Comparison: Friction and Efficiency

Ball bearings exhibit lower friction coefficients, typically ranging from 0.001 to 0.005, resulting in higher mechanical efficiency and reduced energy losses compared to journal bearings. Journal bearings operate on a hydrodynamic lubrication regime that can handle higher load capacities but generally have higher friction due to fluid shear, with coefficients around 0.01 to 0.03 under normal conditions. The overall efficiency of ball bearings often exceeds 95%, making them optimal for high-speed applications, while journal bearings excel in heavy-load, low-speed scenarios despite slightly lower efficiency.

Durability and Maintenance Requirements

Ball bearings generally offer higher durability under high-speed and heavy-load conditions due to their rolling element design, which reduces friction and wear. Journal bearings, relying on a thin film of lubricant to separate sliding surfaces, require more frequent maintenance to monitor and replenish lubrication and prevent metal-to-metal contact. The maintenance demands of journal bearings are higher, but they can provide smoother operation and better shock load absorption in certain applications.

Applications: Where Ball Bearings Excel

Ball bearings excel in high-speed and precise applications such as electric motors, robotics, and aerospace components due to their low friction and ability to handle both radial and axial loads. They are ideal for environments requiring smooth rotation and minimal maintenance, including automotive wheel hubs, machinery spindles, and hard disk drives. Compared to journal bearings, ball bearings provide superior performance in conditions demanding quick startup and shutdown cycles or frequent changes in load direction.

Applications: Best Uses for Journal Bearings

Journal bearings excel in high-load, low-speed applications such as heavy machinery, turbines, and internal combustion engines due to their ability to support substantial radial loads and provide smooth, stable rotation. Their self-lubricating properties and durability make them ideal for continuous operation in industrial equipment, power plants, and automotive engines where reliability and maintenance intervals are critical. Unlike ball bearings, journal bearings perform better under shock loads and misalignment, making them suitable for applications requiring robust performance under harsh conditions.

Cost Considerations and Longevity

Ball bearings generally have higher upfront costs due to precision manufacturing and materials but offer longer service life with lower maintenance needs, making them cost-effective over time. Journal bearings typically require lower initial investment but suffer from more frequent maintenance and shorter lifespan due to increased wear under heavy loads. Selecting between ball and journal bearings depends on balancing initial cost constraints with desired operational longevity and maintenance expenses.

Choosing the Right Bearing for Your Application

Selecting the right bearing for your application depends on load, speed, and lubrication requirements; ball bearings excel in high-speed and low-friction scenarios, providing precise rotational movement, while journal bearings are better suited for heavy loads and shock absorption in slower-speed applications. Ball bearings offer superior performance in environments where minimal friction and accurate positioning are critical, whereas journal bearings provide greater durability and load-carrying capacity through conformal surfaces supporting the shaft. Consider operational conditions, maintenance needs, and cost-effectiveness to ensure optimal bearing performance and longevity.

Ball bearing Infographic

libterm.com

libterm.com