Understanding the mechanics of materials reveals how substances behave under various forces, stresses, and strains, ensuring structural integrity and safety. This knowledge is crucial for designing and analyzing everything from bridges to aircraft components. Explore the rest of the article to deepen your grasp on how materials respond and how it impacts engineering decisions.

Table of Comparison

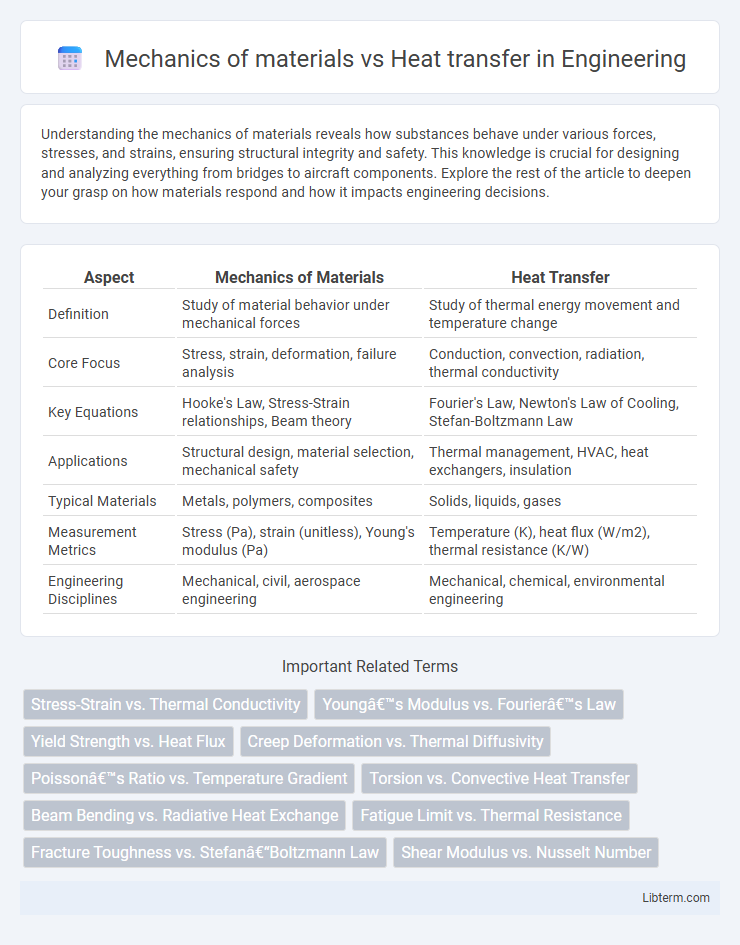

| Aspect | Mechanics of Materials | Heat Transfer |

|---|---|---|

| Definition | Study of material behavior under mechanical forces | Study of thermal energy movement and temperature change |

| Core Focus | Stress, strain, deformation, failure analysis | Conduction, convection, radiation, thermal conductivity |

| Key Equations | Hooke's Law, Stress-Strain relationships, Beam theory | Fourier's Law, Newton's Law of Cooling, Stefan-Boltzmann Law |

| Applications | Structural design, material selection, mechanical safety | Thermal management, HVAC, heat exchangers, insulation |

| Typical Materials | Metals, polymers, composites | Solids, liquids, gases |

| Measurement Metrics | Stress (Pa), strain (unitless), Young's modulus (Pa) | Temperature (K), heat flux (W/m2), thermal resistance (K/W) |

| Engineering Disciplines | Mechanical, civil, aerospace engineering | Mechanical, chemical, environmental engineering |

Introduction to Mechanics of Materials and Heat Transfer

Mechanics of Materials studies the behavior of solid materials under various types of loading, emphasizing concepts such as stress, strain, elasticity, and deformation to analyze structural integrity and material performance. Heat Transfer explores the mechanisms of thermal energy movement through conduction, convection, and radiation, focusing on temperature distribution and heat flux in solids, liquids, and gases. Both disciplines apply fundamental principles of physics and mathematics to solve engineering problems related to structural design and thermal management.

Fundamental Concepts and Definitions

Mechanics of materials studies the behavior of solid materials under external forces, emphasizing stress, strain, elasticity, and plasticity to predict deformation and failure. Heat transfer focuses on the mechanisms of thermal energy movement through conduction, convection, and radiation, governed by Fourier's law, Newton's law of cooling, and the Stefan-Boltzmann law. Both fields rely on core principles: mechanics of materials on material properties and force equilibrium, and heat transfer on energy conservation and temperature gradients.

Key Principles in Mechanics of Materials

Mechanics of materials centers on understanding stress, strain, and deformation in solid structures under various loading conditions, employing key principles like Hooke's Law and the concepts of axial, torsional, and bending stresses. It analyzes material behavior through stress-strain relationships, elastic and plastic deformation, and factors like yield strength and modulus of elasticity. Heat transfer, in contrast, deals primarily with the modes of thermal energy transfer--conduction, convection, and radiation--focusing on temperature gradients and heat flux without directly addressing mechanical stresses or material deformation.

Core Processes in Heat Transfer

Heat transfer encompasses conduction, convection, and radiation as its core processes, each involving distinct mechanisms of energy transfer through solids, fluids, and electromagnetic waves. Mechanics of materials primarily deals with stress, strain, and deformation under various forces, focusing on material behavior rather than thermal energy exchange. Understanding heat transfer processes is crucial for designing thermal systems, whereas mechanics of materials underpins structural integrity and mechanical performance.

Material Behavior Under Mechanical Stress vs Thermal Loads

Material behavior under mechanical stress involves deformation, yielding, and failure modes such as fracture or fatigue, which are characterized by stress-strain relationships and mechanical properties like elasticity, plasticity, and toughness. In contrast, heat transfer focuses on thermal loads causing temperature gradients, thermal expansion, and associated stresses, governed by conduction, convection, and radiation principles. Understanding both mechanical and thermal responses is critical for designing materials and structures that withstand combined mechanical and thermal stresses without performance degradation.

Mathematical Models and Governing Equations

Mechanical behavior in Mechanics of Materials is primarily governed by constitutive equations such as Hooke's Law and stress-strain relations, formulated through partial differential equations like the Navier-Cauchy equations for elasticity. Heat Transfer relies on the heat conduction equation, also known as Fourier's law in differential form, describing temperature distribution through time-dependent or steady-state heat conduction models. Both disciplines utilize governing equations derived from conservation laws but differ in focus: Mechanics emphasizes deformation and stress fields, while Heat Transfer concentrates on thermal energy distribution and flux.

Experimental Methods and Measurement Techniques

Experimental methods in mechanics of materials emphasize strain gauges, extensometers, and load cells to measure stress, strain, and deformation in solids. Heat transfer experiments primarily utilize thermocouples, infrared cameras, and heat flux sensors to capture temperature gradients and heat flow rates. Both fields rely on precise calibration and data acquisition systems to ensure accuracy in mechanical and thermal property measurements.

Engineering Applications: Structures vs Thermal Systems

Mechanics of materials focuses on analyzing stress, strain, and deformation in structural components, essential for designing safe bridges, buildings, and mechanical parts. Heat transfer investigates conduction, convection, and radiation to optimize thermal systems like heat exchangers, HVAC units, and electronic cooling devices. Engineers apply mechanics for load-bearing structures and heat transfer for managing temperature in engines, power plants, and manufacturing processes.

Interdisciplinary Connections and Overlapping Areas

Mechanics of materials and heat transfer intersect in the study of thermomechanical behavior where temperature changes induce stress, strain, and material deformation. This interdisciplinary connection is crucial in designing components subjected to thermal loads, such as turbine blades and electronic devices, where accurate modeling of both mechanical properties and thermal conductivity ensures reliability and performance. Advanced simulations often integrate principles from both fields to predict failure mechanisms and optimize material selection under combined thermal and mechanical stresses.

Future Trends and Research Directions

Mechanics of materials is advancing through the integration of smart materials and nanotechnology to enhance structural performance and durability, with research focusing on multiscale modeling and additive manufacturing techniques. Heat transfer studies are increasingly leveraging phase-change materials and micro/nanoscale heat transfer mechanisms to improve energy efficiency in electronics and renewable energy systems. Future trends emphasize interdisciplinary approaches combining materials science, computational methods, and experimental analysis to address challenges in thermal management and mechanical reliability.

Mechanics of materials Infographic

libterm.com

libterm.com