Ultimate tensile strength measures the maximum stress a material can withstand while being stretched or pulled before breaking, serving as a critical indicator of durability and performance in engineering applications. Understanding this property helps you select the right materials for construction, manufacturing, and design projects that demand high resilience. Explore the rest of the article to learn how ultimate tensile strength influences material choice and structural integrity.

Table of Comparison

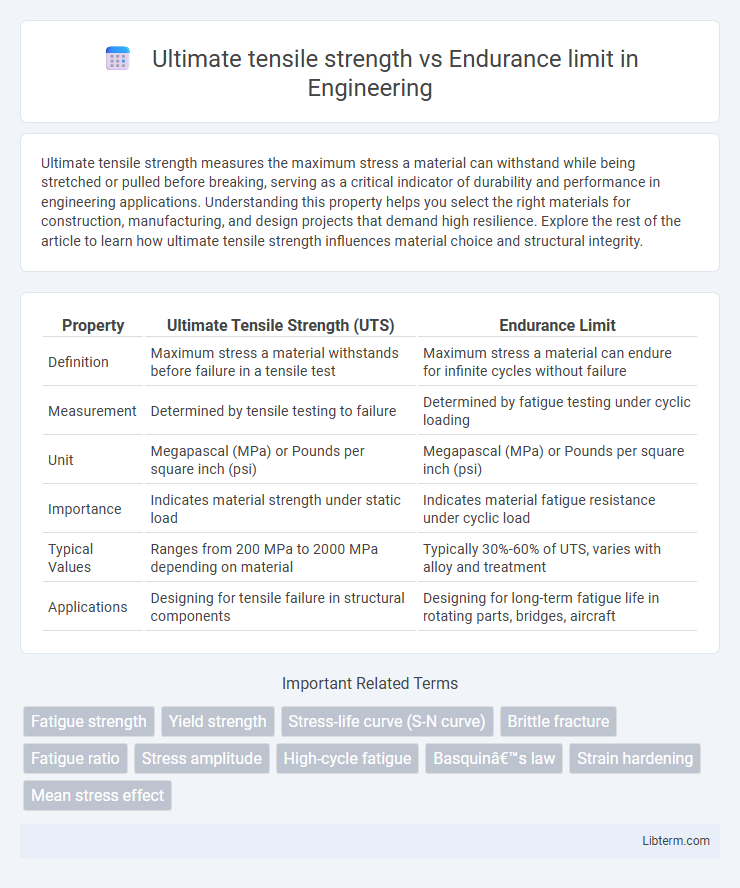

| Property | Ultimate Tensile Strength (UTS) | Endurance Limit |

|---|---|---|

| Definition | Maximum stress a material withstands before failure in a tensile test | Maximum stress a material can endure for infinite cycles without failure |

| Measurement | Determined by tensile testing to failure | Determined by fatigue testing under cyclic loading |

| Unit | Megapascal (MPa) or Pounds per square inch (psi) | Megapascal (MPa) or Pounds per square inch (psi) |

| Importance | Indicates material strength under static load | Indicates material fatigue resistance under cyclic load |

| Typical Values | Ranges from 200 MPa to 2000 MPa depending on material | Typically 30%-60% of UTS, varies with alloy and treatment |

| Applications | Designing for tensile failure in structural components | Designing for long-term fatigue life in rotating parts, bridges, aircraft |

Introduction to Ultimate Tensile Strength and Endurance Limit

Ultimate tensile strength (UTS) defines the maximum stress a material can withstand while being stretched or pulled before breaking. Endurance limit represents the highest stress amplitude a material can endure for an infinite number of loading cycles without failure. Understanding both UTS and endurance limit is crucial for designing components subjected to static and cyclic loads to ensure reliability and structural integrity.

Definitions: Ultimate Tensile Strength vs Endurance Limit

Ultimate tensile strength (UTS) represents the maximum stress a material can withstand while being stretched or pulled before breaking, measured in units such as megapascals (MPa). Endurance limit, also known as fatigue limit, is the maximum stress level a material can endure for an infinite number of load cycles without failure, commonly relevant for ferrous metals. UTS indicates the peak load capacity under a single application, whereas endurance limit defines durability under repeated loading conditions.

Material Behavior: Static vs Cyclic Loading

Ultimate tensile strength (UTS) measures a material's maximum resistance under static loading before failure, representing the peak stress a material can withstand in a single application. Endurance limit defines the maximum stress a material can endure indefinitely under cyclic loading without fatigue failure, crucial for components subjected to repeated stress variations. Understanding the distinction between UTS and endurance limit is essential for predicting material behavior, ensuring safety, and optimizing design in static versus cyclic load environments.

Testing Methods for Tensile Strength and Endurance Limit

Tensile strength testing is typically performed using a universal testing machine that applies a uniaxial tensile load to a specimen until failure, measuring the maximum stress the material withstands. Endurance limit testing involves cyclic loading on a fatigue testing machine, subjecting the material to repeated stress cycles to determine the maximum stress amplitude it can endure without failure over a specified number of cycles, often 10^6 or more. Both tests use standardized specimens and protocols, such as ASTM E8 for tensile testing and ASTM E466 for fatigue testing, ensuring consistent and reliable measurement of ultimate tensile strength and endurance limit.

Factors Influencing Ultimate Tensile Strength

Ultimate tensile strength (UTS) depends on material composition, grain size, heat treatment, and strain rate, as these factors determine the material's ability to withstand maximum stress before fracture. Alloying elements and microstructural characteristics, such as phase distribution and dislocation density, significantly influence UTS by enhancing or reducing material strength. In contrast, endurance limit relates to fatigue resistance under cyclic loading, highlighting the different mechanical performance aspects each property addresses.

Factors Affecting Endurance Limit

Endurance limit is primarily affected by factors such as surface finish, size, temperature, and material defects, which influence the material's ability to resist fatigue under cyclic loading. Ultimate tensile strength measures the maximum stress a material can withstand before failure, but endurance limit specifically relates to the stress level below which fatigue failure does not occur for an infinite number of cycles. Surface roughness and microstructural imperfections significantly reduce the endurance limit by acting as stress concentrators, whereas tensile strength is more dependent on overall material composition and microstructure.

Importance in Engineering Applications

Ultimate tensile strength (UTS) measures the maximum stress a material can withstand before failure, critical for ensuring structural components can handle peak loads without breaking. Endurance limit represents the maximum stress a material can endure for an infinite number of cycles without fatigue failure, vital for the durability of parts subjected to repeated loading such as gears, shafts, and bridges. Both properties guide engineers in selecting materials that balance strength and longevity, optimizing safety and performance in mechanical design.

Comparison Table: UTS vs Endurance Limit

Ultimate tensile strength (UTS) measures the maximum stress a material can withstand before failure, typically expressed in megapascals (MPa), while the endurance limit represents the maximum cyclic stress a material can endure indefinitely without failure. A comparison table highlights that UTS values are generally higher than endurance limits since UTS relates to static loading, whereas endurance limit pertains to fatigue resistance under repeated stress. Metals like steel often exhibit a distinct endurance limit at about 40-60% of their UTS, whereas non-ferrous metals may lack a well-defined endurance limit, emphasizing the importance of selecting materials based on specific mechanical performance requirements.

Material Selection Based on Strength Requirements

Ultimate tensile strength (UTS) indicates the maximum stress a material can withstand before failure, crucial for applications requiring high load-bearing capacity. Endurance limit defines the maximum stress a material can endure for infinite cycles without fatigue failure, essential in components subjected to repetitive loading. Selecting materials based on UTS is ideal for static strength demands, while the endurance limit is critical for durability in cyclic stress environments, ensuring reliability and longevity in mechanical design.

Summary and Key Takeaways

Ultimate tensile strength (UTS) represents the maximum stress a material can withstand under a single tensile load before failure, while the endurance limit is the maximum cyclic stress level a material can endure indefinitely without fatigue failure. Materials with a high UTS do not necessarily have a high endurance limit, as fatigue resistance depends on microstructure and surface conditions. Understanding both properties is crucial for designing components subjected to static and cyclic loads to ensure safety and durability.

Ultimate tensile strength Infographic

libterm.com

libterm.com