Center load washing machines offer superior washing performance by evenly distributing clothes around a central agitator, reducing wear on your fabrics. Their ergonomic design allows easy loading and unloading, making laundry tasks quicker and less strenuous. Discover how choosing a center load washer can transform your laundry routine by reading the rest of the article.

Table of Comparison

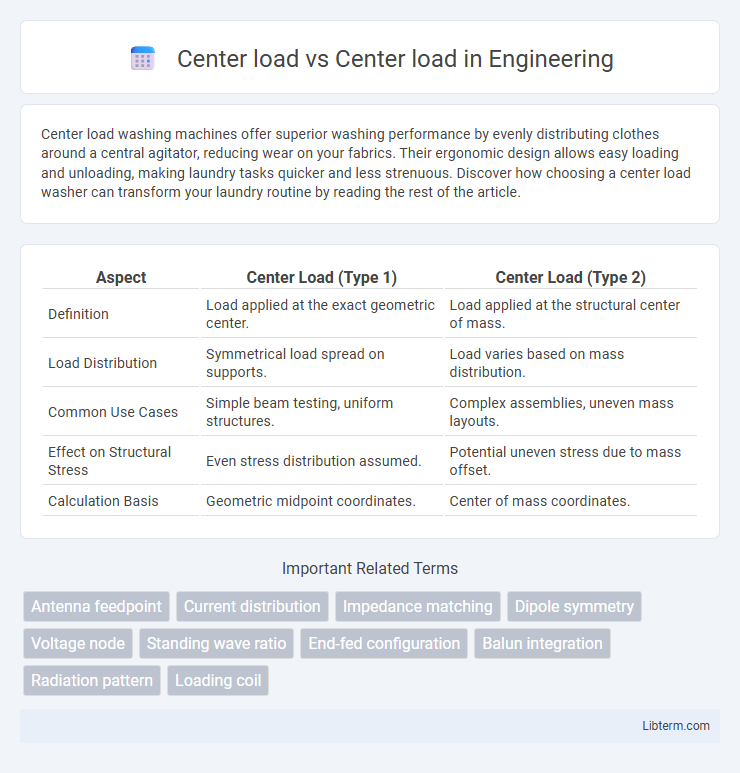

| Aspect | Center Load (Type 1) | Center Load (Type 2) |

|---|---|---|

| Definition | Load applied at the exact geometric center. | Load applied at the structural center of mass. |

| Load Distribution | Symmetrical load spread on supports. | Load varies based on mass distribution. |

| Common Use Cases | Simple beam testing, uniform structures. | Complex assemblies, uneven mass layouts. |

| Effect on Structural Stress | Even stress distribution assumed. | Potential uneven stress due to mass offset. |

| Calculation Basis | Geometric midpoint coordinates. | Center of mass coordinates. |

Understanding Center Load: Definition and Importance

Center load refers to the point where the entire weight or force is concentrated at the center of an object or system, crucial for maintaining balance and structural integrity. Understanding center load ensures accurate calculations in engineering, construction, and logistics, minimizing risks of tipping, uneven stress distribution, or structural failure. Proper management of center load optimizes stability and performance in various applications, from vehicle design to material handling.

Center Load vs Center Load: Key Differences

Center load refers to placing a load at the geometric center of an object or structure, ensuring balanced weight distribution and minimizing shear forces. In contrast, center load can also describe centralized load handling in mechanisms or logistics, emphasizing efficiency and stability in load management. Key differences lie in the context of application: structural engineering centers on physical balance, whereas operational use focuses on optimized load positioning for performance.

Structural Impacts of Center Load Placement

Center load placement significantly influences structural stability by affecting load distribution and stress concentrations within a building's framework. Proper alignment of the center load with primary support elements reduces bending moments and shear forces, enhancing overall structural integrity. Misaligned center loads can cause uneven deflections and potential failure points, demanding careful engineering analysis for optimal design.

Load Distribution Efficiency: Center Load Comparison

Center load configurations optimize load distribution by evenly balancing weight around the central axis, enhancing stability and reducing stress on structural components. Compared to off-center load arrangements, center load systems minimize torque and shear forces, resulting in improved mechanical efficiency and extended equipment lifespan. Efficient center load distribution is critical in applications such as crane operations, industrial lifting, and vehicle design, where precise balance ensures operational safety and performance.

Material Stress Under Center Load Conditions

Center load conditions subject materials to concentrated stress at the exact midpoint, resulting in a uniform distribution of compressive or tensile forces that test the material's intrinsic strength. Stress analysis under center load reveals critical insights into the elasticity, yield strength, and fracture toughness of materials like steel, aluminum, or composites. Understanding material behavior under these conditions informs design optimization for structural elements, ensuring resilience against deformation and failure.

Installation and Maintenance Considerations

Center load equipment simplifies installation by providing balanced weight distribution that reduces structural stress and alignment issues. Maintenance is streamlined due to easier access of internal components from the center, allowing quicker inspections and repairs. Proper alignment during installation minimizes wear and prolongs equipment lifespan, ensuring reliable operation.

Performance Analysis: Center Load Variations

Center load variations significantly impact performance analysis by influencing system stability and operational efficiency. Precise measurement of center load distribution enables optimization of load-bearing components to prevent overloading and minimize mechanical stress. Evaluating center load fluctuations helps identify potential failure points and improve the reliability of structural or mechanical systems.

Common Applications for Center Load Configurations

Center load configurations are commonly used in industrial machinery, including robotics and conveyor systems, due to their balanced weight distribution and enhanced stability. These setups optimize load handling in manufacturing processes like assembly lines and material transport, improving operational efficiency and reducing wear on mechanical components. Their ability to evenly distribute force makes them ideal for applications requiring precise control and high load capacity.

Advantages and Disadvantages of Center Load Types

Center load types provide balanced weight distribution, enhancing stability and reducing structural stress, which is advantageous in applications such as mechanical shafts and conveyor systems. However, they may require precise alignment and can be more complex to manufacture, leading to higher costs and potential maintenance challenges. Understanding the trade-offs between center load configurations is crucial for optimizing performance in engineering designs and industrial processes.

Choosing the Right Center Load for Your Project

Choosing the right center load depends on factors such as load weight, material type, and project specifications, impacting stability and efficiency. Opt for a high-capacity center load when handling heavy or irregularly shaped materials to ensure balanced force distribution and reduce strain on equipment. An optimal center load enhances project safety, operational performance, and longevity of machinery by minimizing wear and preventing structural failure.

Center load Infographic

libterm.com

libterm.com