Mortise and tenon joints provide exceptional strength and stability by interlocking two pieces of wood with precise craftsmanship. This traditional woodworking technique ensures a durable connection ideal for furniture and frame construction. Discover how mastering this joint can elevate your woodworking projects by reading the full article.

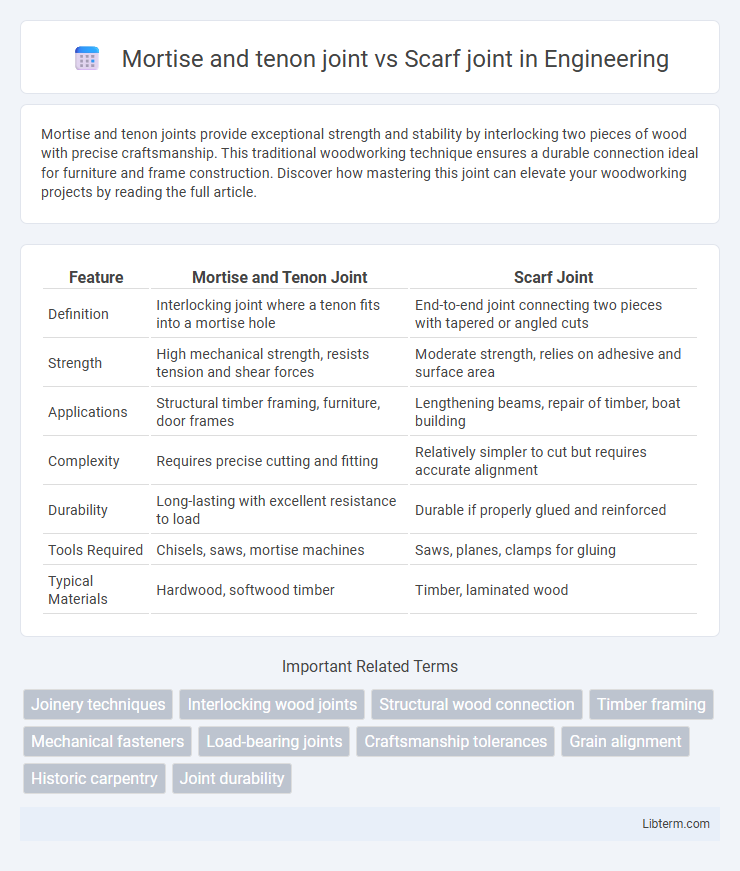

Table of Comparison

| Feature | Mortise and Tenon Joint | Scarf Joint |

|---|---|---|

| Definition | Interlocking joint where a tenon fits into a mortise hole | End-to-end joint connecting two pieces with tapered or angled cuts |

| Strength | High mechanical strength, resists tension and shear forces | Moderate strength, relies on adhesive and surface area |

| Applications | Structural timber framing, furniture, door frames | Lengthening beams, repair of timber, boat building |

| Complexity | Requires precise cutting and fitting | Relatively simpler to cut but requires accurate alignment |

| Durability | Long-lasting with excellent resistance to load | Durable if properly glued and reinforced |

| Tools Required | Chisels, saws, mortise machines | Saws, planes, clamps for gluing |

| Typical Materials | Hardwood, softwood timber | Timber, laminated wood |

Introduction to Mortise and Tenon vs Scarf Joints

Mortise and tenon joints provide strong, interlocking connections by fitting a projecting tenon into a precise mortise cavity, widely used in traditional woodworking for durability and load-bearing structures. Scarf joints join two wood pieces end-to-end by overlapping and angling cuts, ensuring an extended length with moderate strength, often used in timber framing and repair work. Understanding the differences in mechanical strength, application, and complexity helps select the appropriate joint for structural integrity and aesthetic finish.

Historical Background of Wood Joinery Techniques

The mortise and tenon joint, dating back over 7,000 years to ancient Egyptian and Chinese woodworking, became a cornerstone of timber framing and furniture construction due to its exceptional strength and simplicity. The scarf joint, utilized by early shipbuilders and carpenters in medieval Europe, evolved as a crucial method for joining two pieces of wood end-to-end to accommodate long beams and structural repairs. Both joints have profoundly influenced traditional craftsmanship and remain fundamental in historical and contemporary woodworking practices.

Structural Overview: What is a Mortise and Tenon Joint?

A mortise and tenon joint consists of a rectangular projection (tenon) on one timber that fits precisely into a corresponding cavity (mortise) on another, creating a strong, interlocking connection commonly used in woodworking and timber framing. This joint is renowned for its ability to bear heavy loads and resist lateral stresses, making it ideal for structural frameworks such as doors, tables, and traditional timber buildings. Its mechanical strength and clean lines offer superior durability compared to a scarf joint, which typically involves overlapping and gluing rather than interlocking components.

Structural Overview: What is a Scarf Joint?

A scarf joint is a woodworking technique used to join two pieces of timber end-to-end by cutting complementary angled surfaces that fit tightly together, creating a longer structural element. Unlike the mortise and tenon joint, which connects pieces at right angles with a protruding tenon fitting into a corresponding mortise, the scarf joint's angled cuts distribute stress along the joint, improving tensile strength and reducing the risk of splitting. Common in timber framing and boatbuilding, scarf joints are optimized for lengthening beams while maintaining structural integrity.

Comparative Strength and Durability

Mortise and tenon joints exhibit superior strength and durability due to their interlocking design, providing enhanced resistance to shear and tensile stresses, making them ideal for load-bearing structures. Scarf joints, while useful for extending timber lengths, generally offer less mechanical strength and rely heavily on adhesive or fasteners, which may degrade over time and reduce joint integrity. The mortise and tenon joint's ability to maintain structural stability under dynamic loads outperforms the scarf joint, particularly in applications requiring long-term resilience.

Applications in Woodworking and Construction

Mortise and tenon joints are extensively used in furniture making and timber framing due to their superior strength and stability for load-bearing structures. Scarf joints are commonly applied in repairing or extending wooden beams and rafters where length continuity is essential but structural loads are moderate. Both joints serve crucial roles in woodworking and construction, with mortise and tenon favored for rigid, long-lasting connections and scarf joints preferred for seamless material extension.

Ease of Fabrication and Assembly

Mortise and tenon joints offer superior ease of assembly due to their self-aligning properties, which reduce the need for clamps or fasteners during construction. Scarf joints generally require more precise cutting and alignment, making fabrication more complex and assembly more time-consuming. For woodworking projects focused on efficiency, mortise and tenon joints provide a more straightforward and reliable solution.

Material Suitability and Limitations

Mortise and tenon joints excel in hardwood applications due to their strong interlocking design, providing superior shear strength and load-bearing capacity compared to scarf joints. Scarf joints are more suitable for softwoods or engineered wood where extending length is necessary but lower mechanical stress is expected; they rely heavily on adhesive strength and precise cutting. Limitations of mortise and tenon include complexity in fabrication and higher material waste, while scarf joints may suffer from reduced durability and susceptibility to delamination under high stress or moisture exposure.

Aesthetic Considerations in Joint Selection

Mortise and tenon joints provide a clean, traditional look with minimal visible seams, enhancing the aesthetic appeal in fine woodworking and furniture making. Scarf joints, often used in lengthening timber, can be less visually striking but offer a distinctive, decorative grain pattern when properly aligned and finished. Choosing between these joints depends on desired visual impact and the balance between structural integrity and surface smoothness.

Choosing the Right Joint for Your Project

Mortise and tenon joints provide exceptional strength and durability, making them ideal for load-bearing structures like furniture frames and door assemblies. Scarf joints are better suited for extending timber length in non-structural applications where aesthetics and seamless appearance are priorities. Selecting the right joint depends on project requirements for strength, appearance, and the specific wood types being used.

Mortise and tenon joint Infographic

libterm.com

libterm.com